Heat exchanger

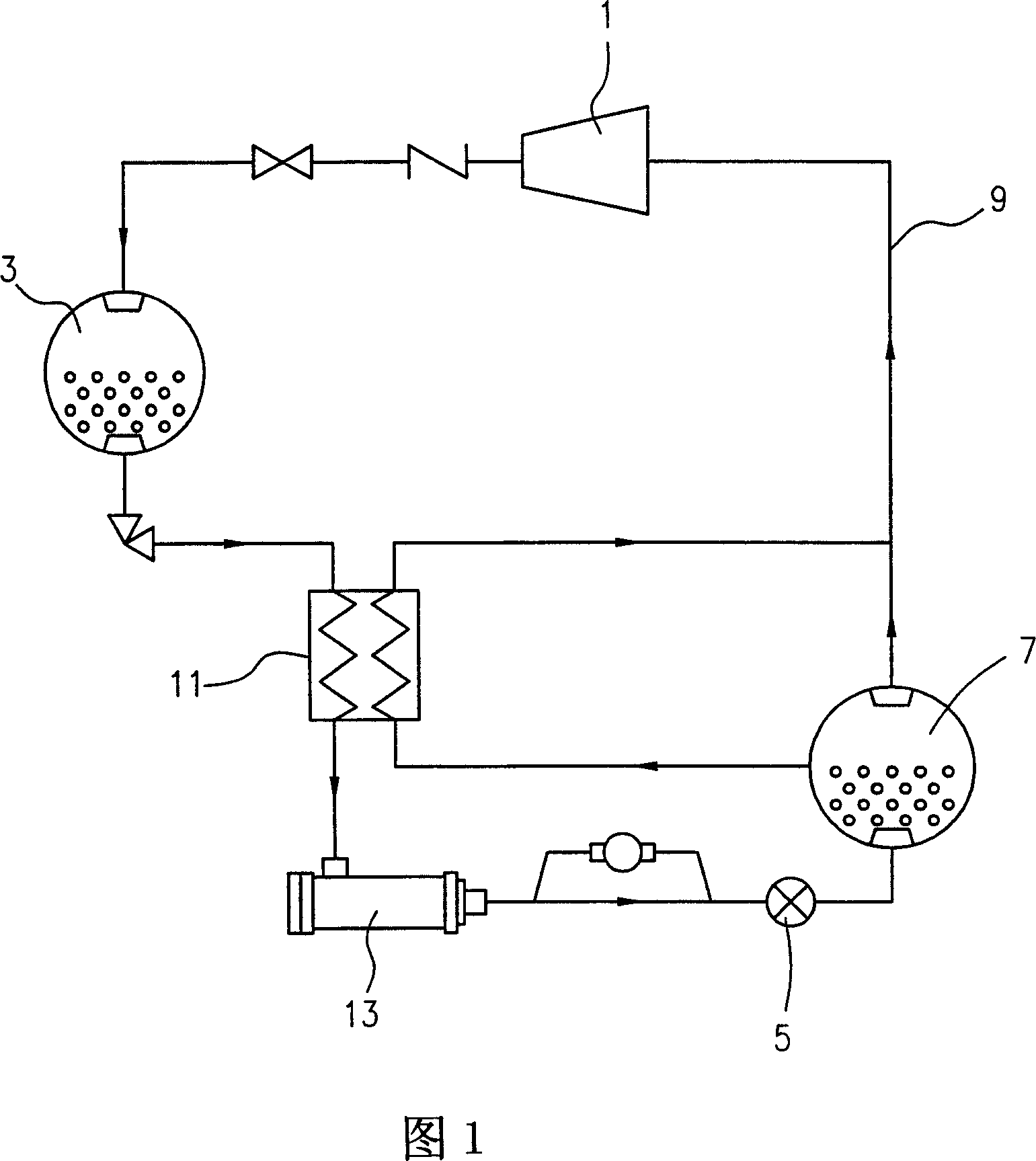

A heat exchanger and heating tube technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of affecting heat exchange efficiency, reducing heat exchange efficiency, increasing flow rate, etc., to improve heat exchange Benefit, enhance heat exchange effect, increase the effect of flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

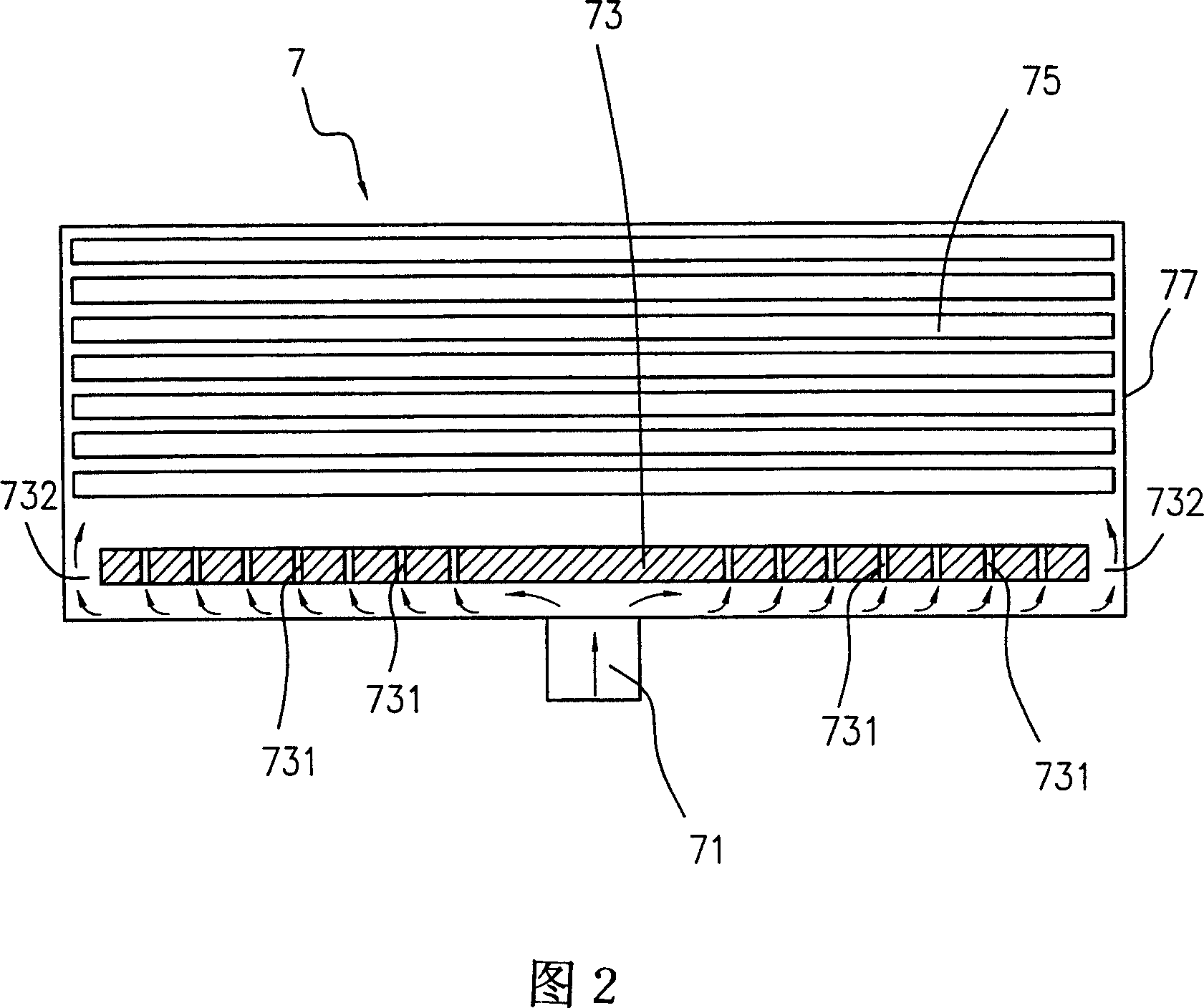

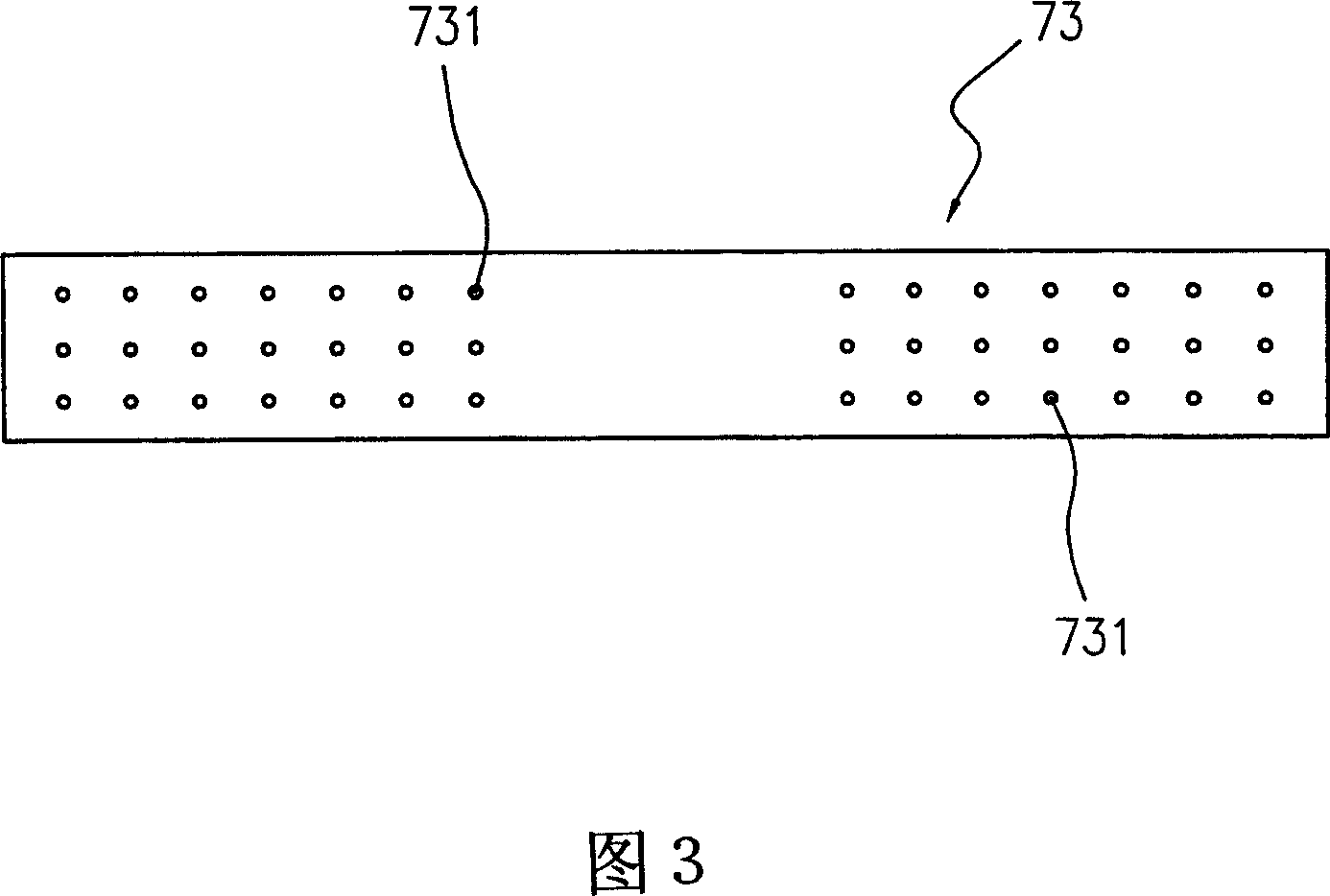

[0051] Please refer to Fig. 4 and Fig. 5 at the same time, wherein, Fig. 4 is a schematic diagram of the internal structure configuration of the flooded evaporator of the present invention, which is used to show the structural configuration when the diverter baffle plate 10 of the present invention is arranged inside the evaporator 7, Fig. 5 Plan view of the splitter baffle 10 of the present invention. The present invention is mainly used in a flooded evaporator 7, but is not limited to a specific chiller or evaporator, and generally belongs to the category of heat exchangers, such as: shell-and-tube heat exchangers, or All kinds of condensers, as long as they must disperse the flow of refrigerant and distribute them evenly on the surface of various types of heating tubes to generate heat exchange effect, they should all belong to the patent application scope of the present invention.

[0052] As shown in the drawings, the same as the known technology, the evaporator 7 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com