Pump-driven two-phase loop heat dissipation system for high-power-density cabinet

A technology of high power density and heat dissipation system, which is applied in the field of pump drive two-phase loop heat dissipation system, to achieve the effect of improving utilization rate, saving floor space and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following embodiments are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

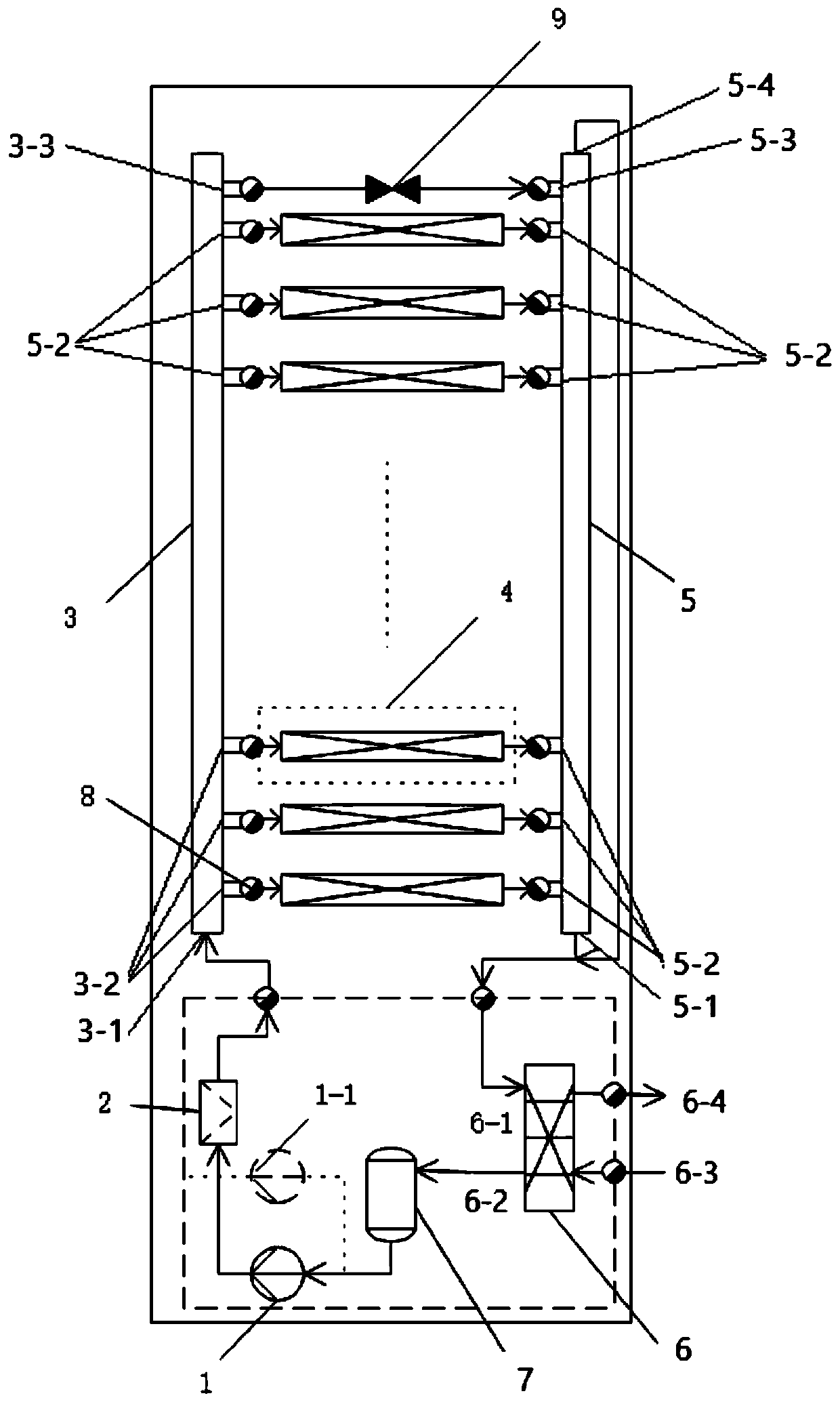

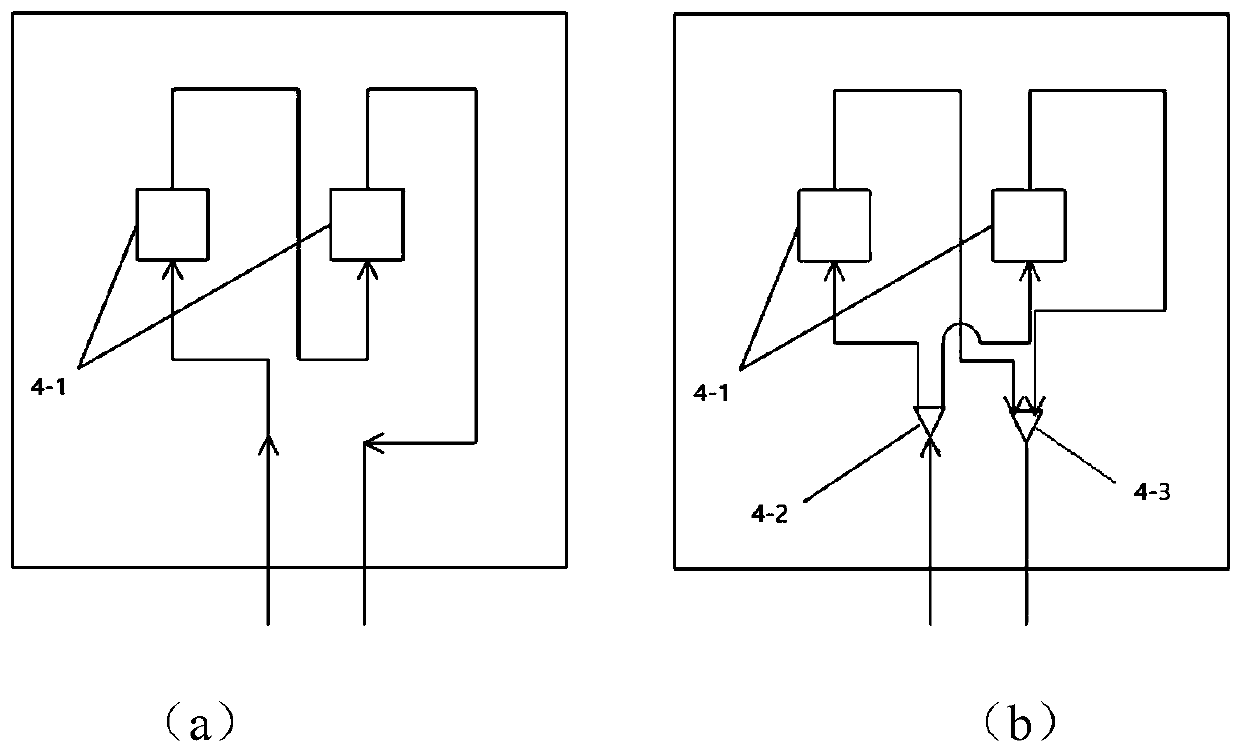

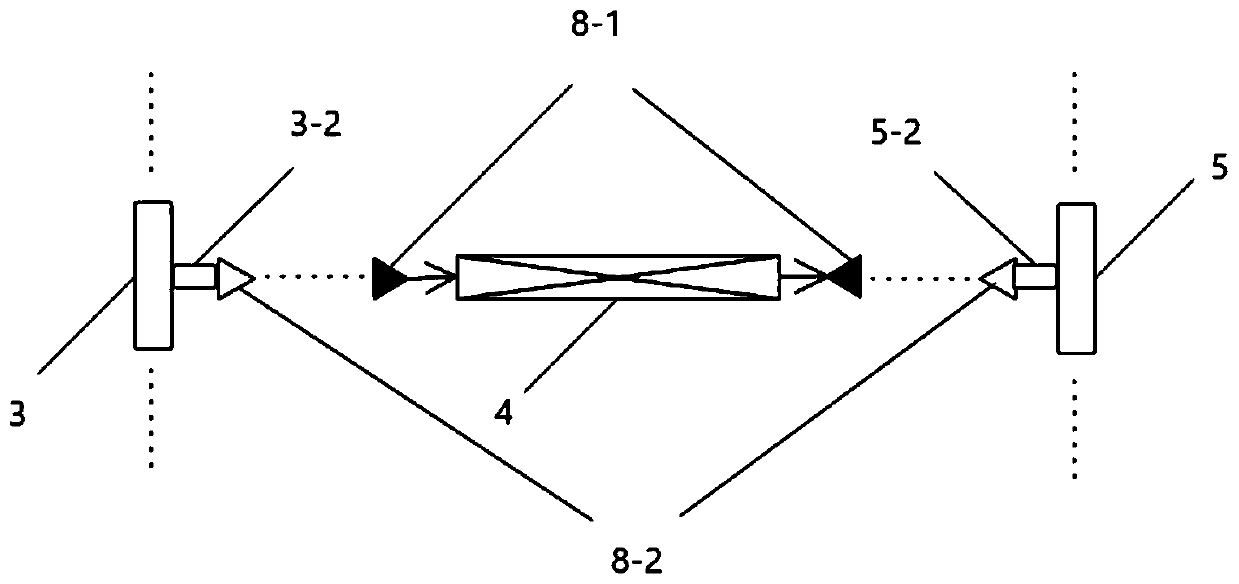

[0035] Such as figure 1 As shown, the pump-driven two-phase loop heat dissipation system for high power density cabinets of the present invention includes a refrigerant liquid storage tank 7, a pump 1, a distribution pipe 3, a plurality of server heat dissipation units 4, a confluence pipe 5 and The heat exchanger 6 communicates with the refrigerant storage tank 7 to form a circulation loop. Among them, the pump 1, the filter 2, the heat exchanger 6 and the refrigerant liquid storage tank 7 are fixed in the drawer-type shelter at the bottom of the cabinet, and the pipeline connection between the shelter and the outside world is completed through a pluggable self-locking joint 8, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com