Intensified heat exchange tube with intersectional zoomed sections of circle-ellipse

An elliptical section, heat exchange tube technology, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of troublesome design and manufacture of heat exchangers, poor pressure resistance of elliptical tubes, small flow resistance, etc. Good heat transfer enhancement performance, wide application range, small flow resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

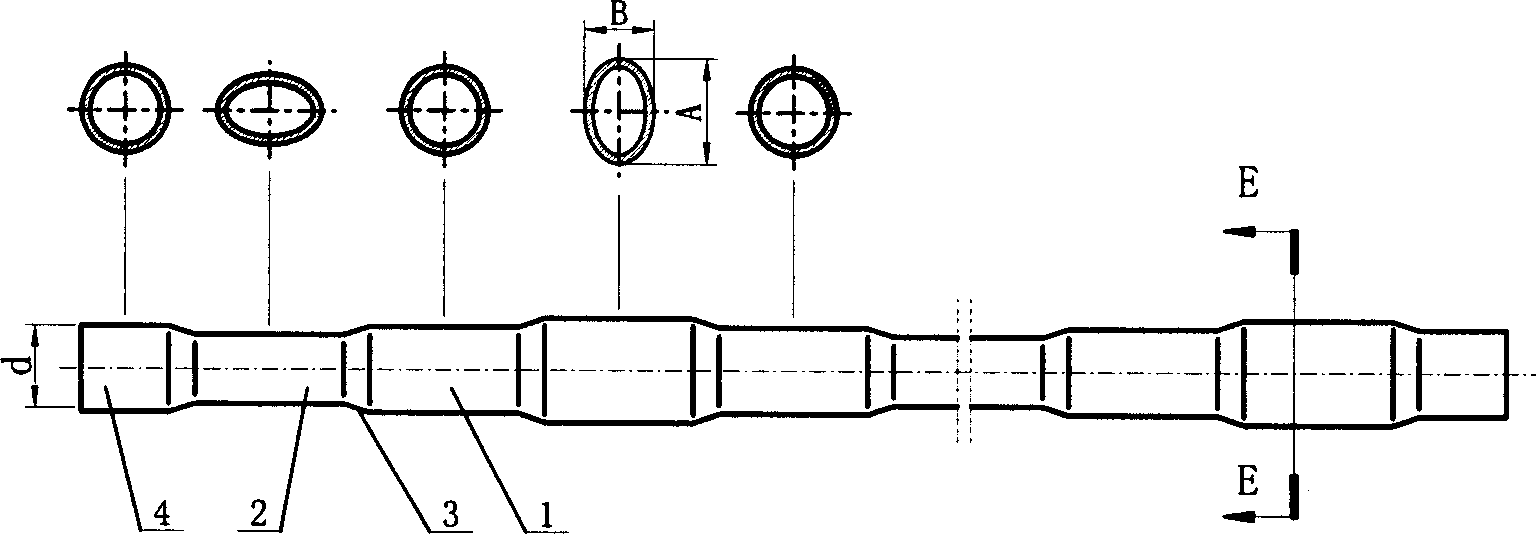

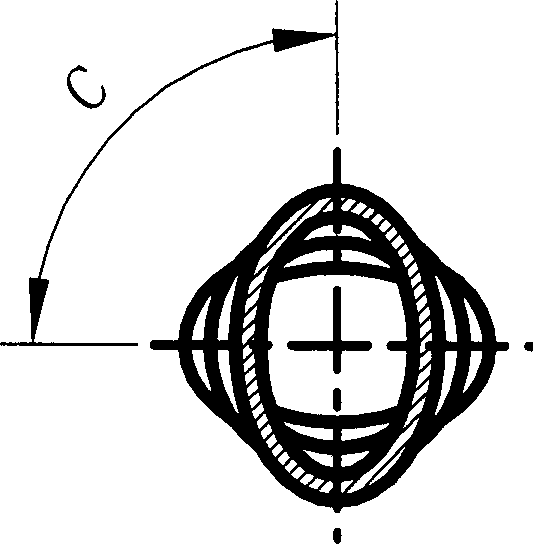

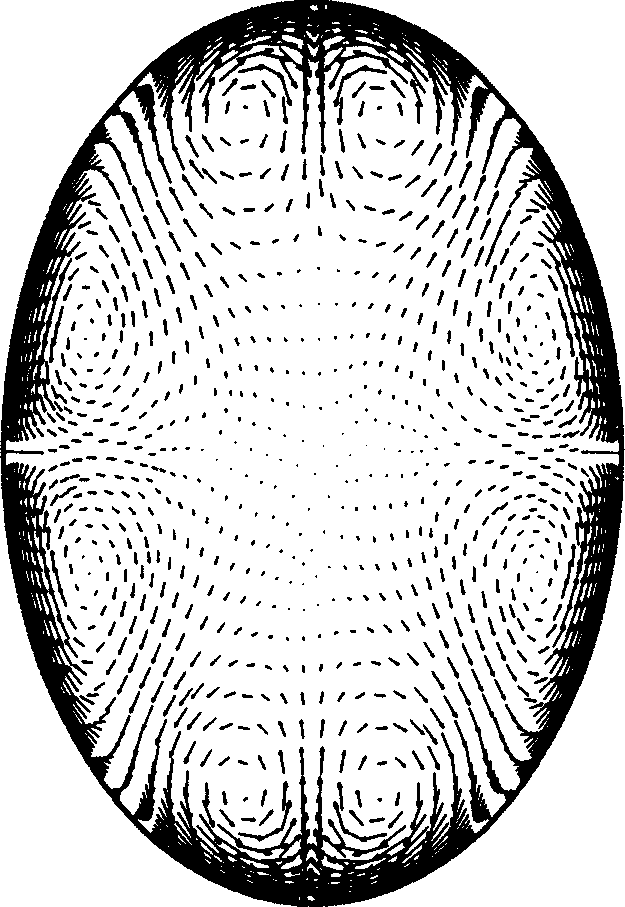

[0015] figure 1 It is a structural schematic diagram of a circle-ellipse section cross-scaling enhanced heat exchange tube provided by the present invention. The enhanced heat exchange tube is composed of several circular tube sections 1, elliptical tube sections 2, circular-elliptical transition sections 3 and inlet circular tube sections 4 at both ends. The length Lc of the round pipe section is determined according to the requirements of pressure resistance, flow resistance, and installation of baffle plates or baffle rods. Generally, Lc / d=0.5~10, where d is the inner diameter of the round pipe. The lengths of each circular pipe section can be equal or unequal. The length Lo of the round tube section at both ends can be 2 to 4 times the thickness of the tube sheet, depending on the needs of its assembly with the tube sheet, and take the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com