Efficient low-temperature vibration vaporizer

A vaporizer, low temperature technology, applied in indirect heat exchangers, heat exchanger types, fixed conduit components, etc., can solve the problems of icing, frosting, and low heat exchange efficiency outside the heat exchange tubes, and reduce icing, The effect of reducing heat transfer resistance and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

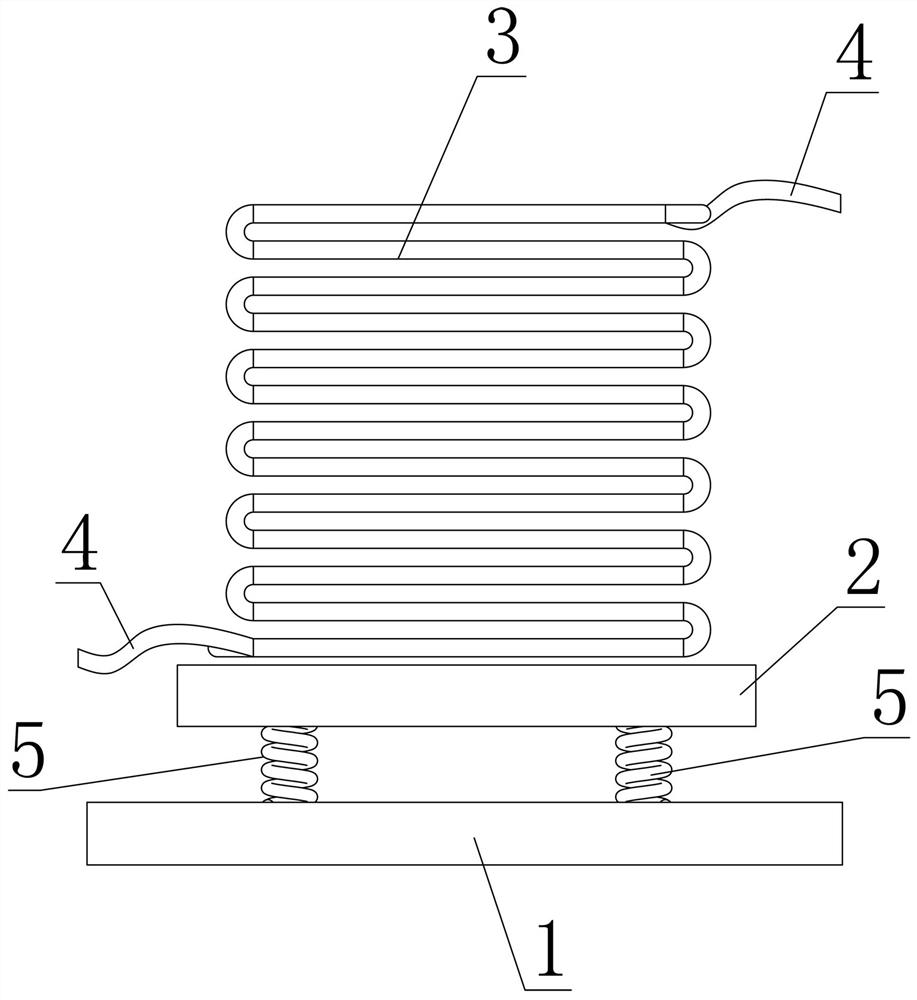

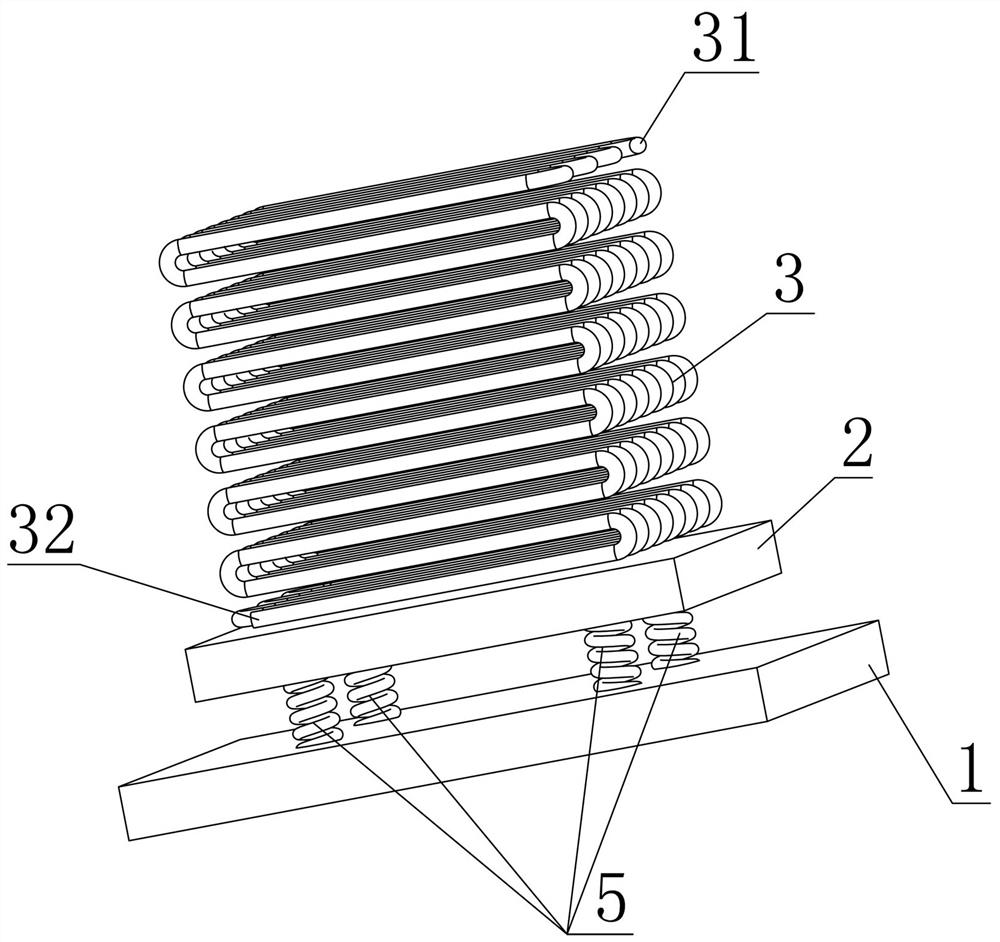

[0016] like figure 1 , figure 2 As shown, the high-efficiency low-temperature vibrating vaporizer includes a bottom plate 1, the bottom plate 1 is a whole flat plate structure, a back plate 2 is arranged above the bottom plate 1, and a heat exchange tube composed of heat exchange tubes is fixed on the back plate 2. The vaporization unit 3, the medium inlet 31 and the medium outlet 32 of the heat exchange vaporization unit 3 are respectively equipped with a low temperature resistant hose 4 for connecting to the hydrogen supply system, and the low temperature resistant hose 4 is used to eliminate the vibration effect of the vaporizer vibration brought to the system; The back plate 2 is installed on the bottom plate 1 through a number of elastic components 5, and the back plate 2 and the heat exchange and vaporization unit 3 can shake relative to the bottom plate 1 through the elastic components 5 when they are naturally excited or forcedly excited; The component 5 is a singl...

specific Embodiment 2

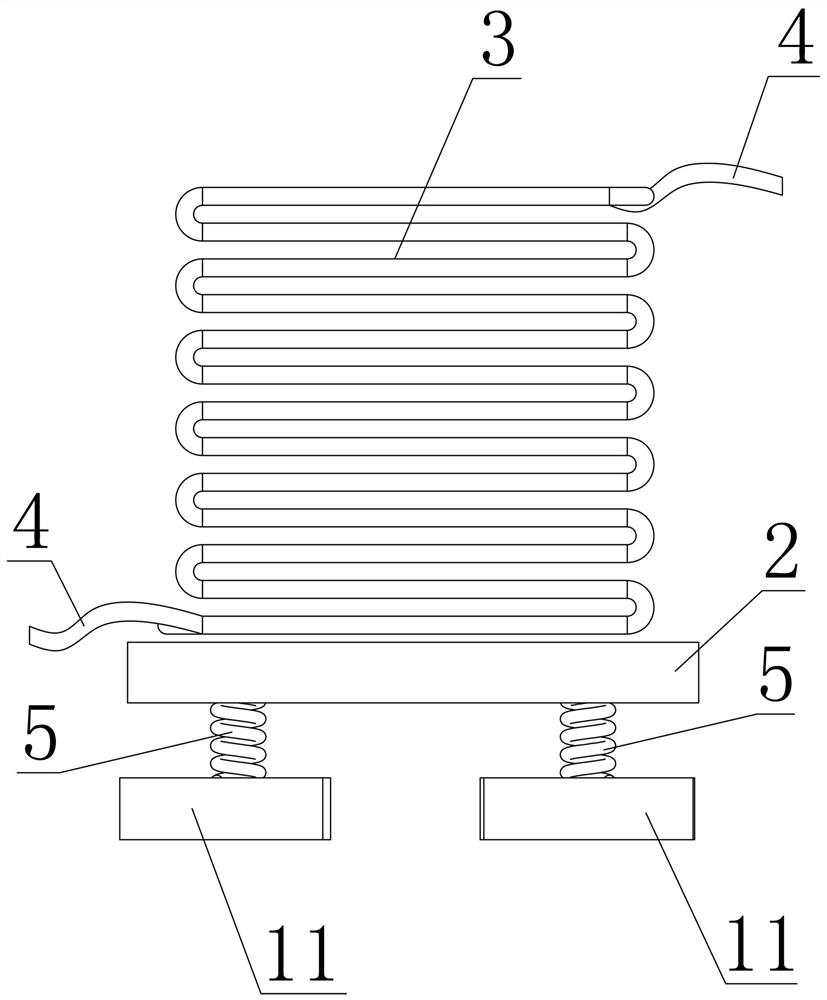

[0017] like image 3 , Figure 4 , Figure 5 As shown, the high-efficiency low-temperature vibrating vaporizer includes a bottom plate, a back plate 2 is arranged above the bottom plate 1, and a heat exchange vaporization unit 3 composed of heat exchange tubes is fixed on the back plate 2. The medium inlet 31 and the medium outlet 32 are respectively equipped with a low temperature resistant hose 4 for connecting to the hydrogen supply system, and the low temperature resistant hose 4 is used to eliminate the vibration effect of the system brought by the vibration of the vaporizer; the back plate 2 passes through several elastic components 5 Installed on the bottom plate 1, the back plate 2 and the heat exchange and vaporization unit 3 can shake relative to the bottom plate 1 through the elastic component 5 when they are naturally excited or forcedly excited; in this embodiment, the bottom plate is composed of four independent flat plates 11. The flat plates 11 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com