Improved gas stove with secondary air channel

A technology for secondary air and gas stoves, applied in the field of gas stoves, can solve the problems of reduced heating efficiency, reduced flame heating capacity, flame elongation, etc., and achieves the effects of being beneficial to convective heat transfer, improving heating efficiency, and prolonging contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

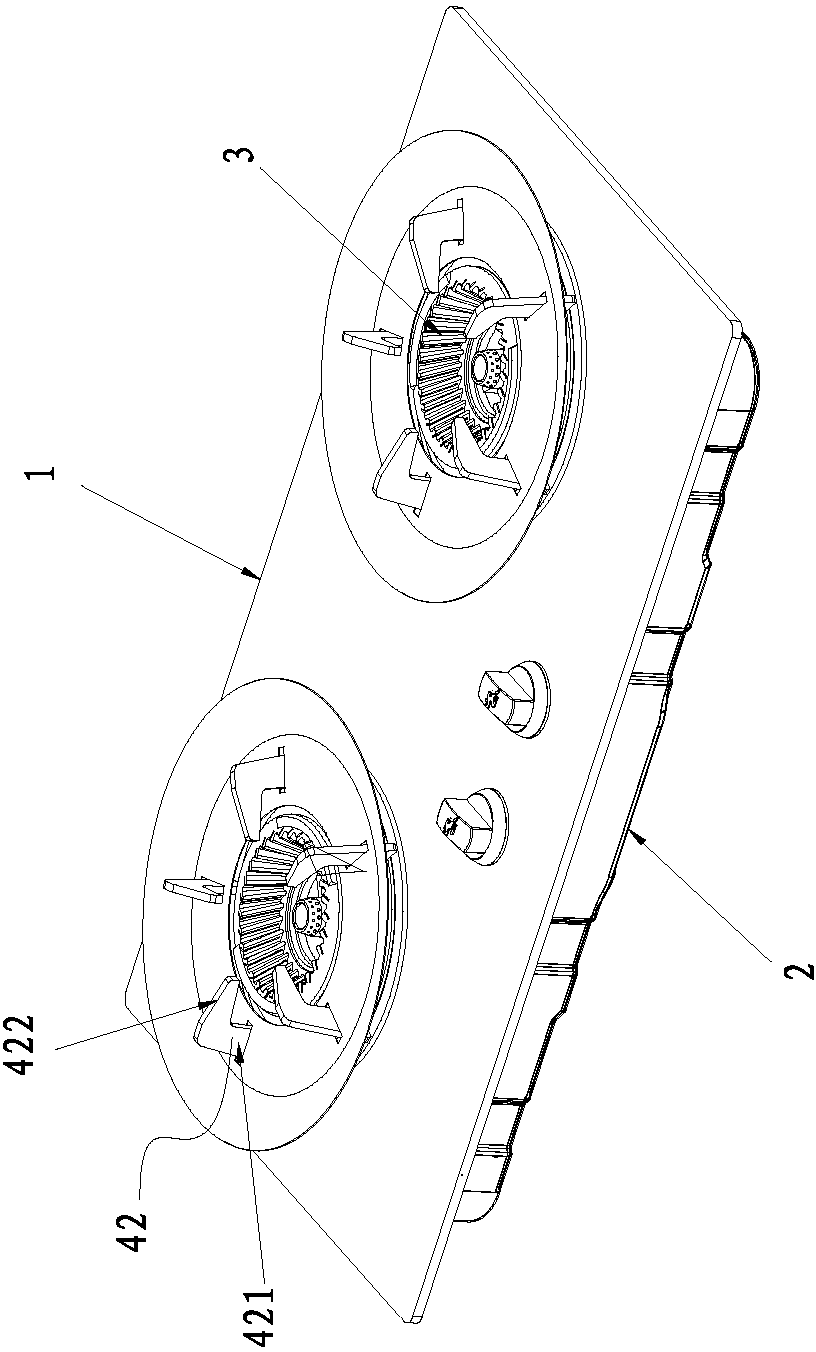

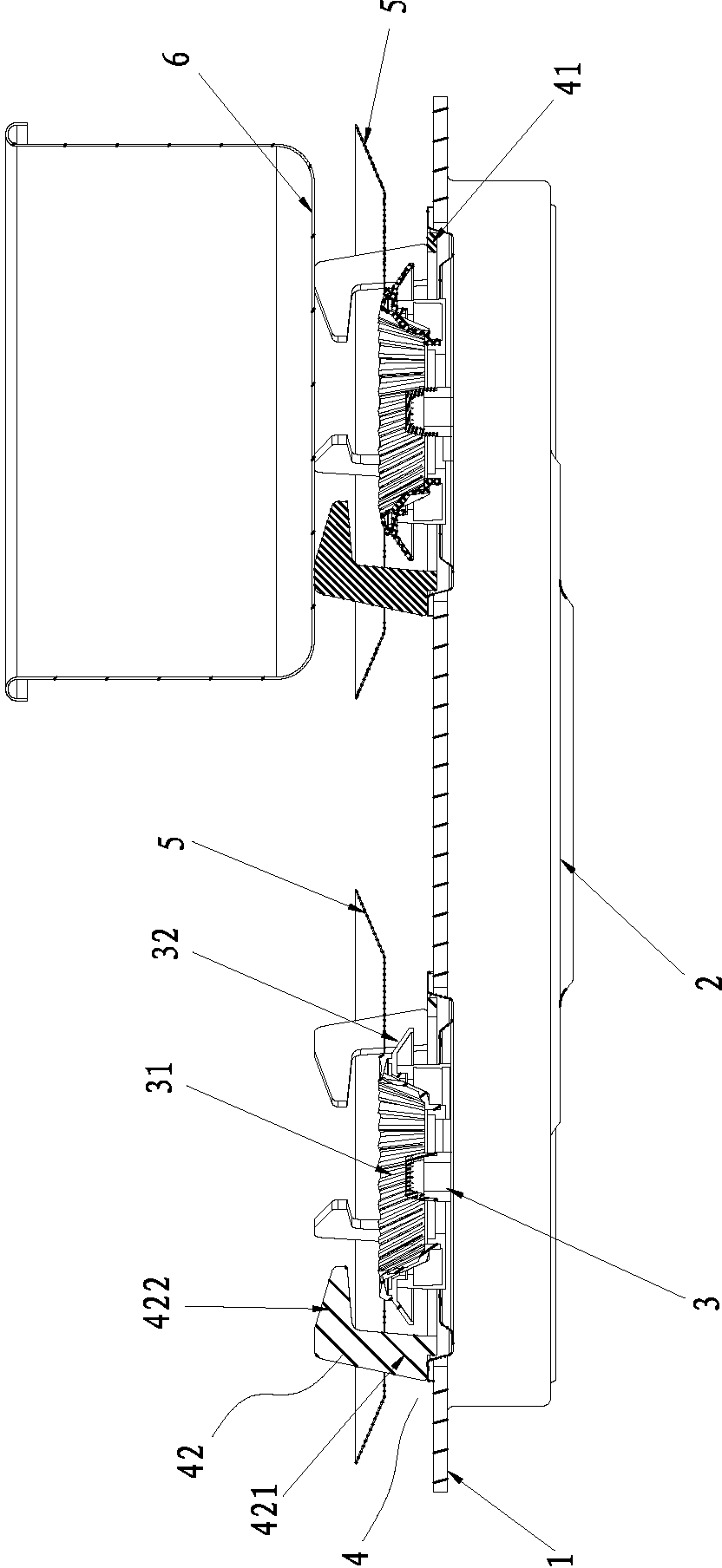

[0016] like figure 1 , figure 2 As shown, a gas stove with improved secondary air passage includes a panel 1, a bottom case 2, an internal swirl burner 3 and a pot support 4, and the pot support 4 includes a bottom ring seat 41 and a leg 42, and the leg 42 includes Supporting feet 421 and horizontal feet 422, the supporting feet 421 are evenly distributed on the bottom ring seat 41; the internal rotation fire burner 3 includes a fire cover 31 and a decorative ring 32;

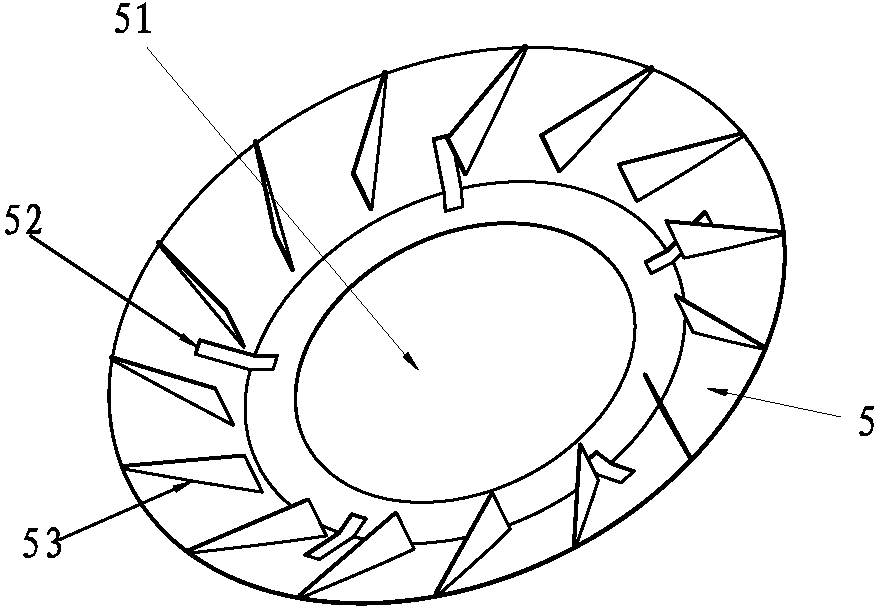

[0017] Also includes a partition cover 5, such as image 3 As shown, the partition cover 5 has a central hole 51, the inner swirling burner 3 is located in the central hole 51, and there is a gap between the inner wall of the central hole 51 and the outer circumference of the inner swirling burner 3.

[0018] There is a gap between the inner wall of the central hole 51 and the outer peripheral wall of the fire cover 31 or the decorative ring 32;

[0019] Fixing holes 52 are arranged on the partition cover 5...

Embodiment 2

[0023] like Figure 4 As shown, the partition cover 5 is located above the internal swirling fire burner 4; the upper part of the partition cover 5 has rotating metal blades 53; the gap between the partition cover 5 and the panel 1 and the central hole 51 constitute the secondary air aisle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com