A vacuum drying system

A technology of vacuum drying and vacuum device, applied in sludge drying, drying solid materials, drying cargo handling, etc., can solve the problems of high energy consumption and low drying efficiency of drying system, so as to increase the convective heat exchange area and improve the heat exchange Thermal efficiency, the effect of improving the degree of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

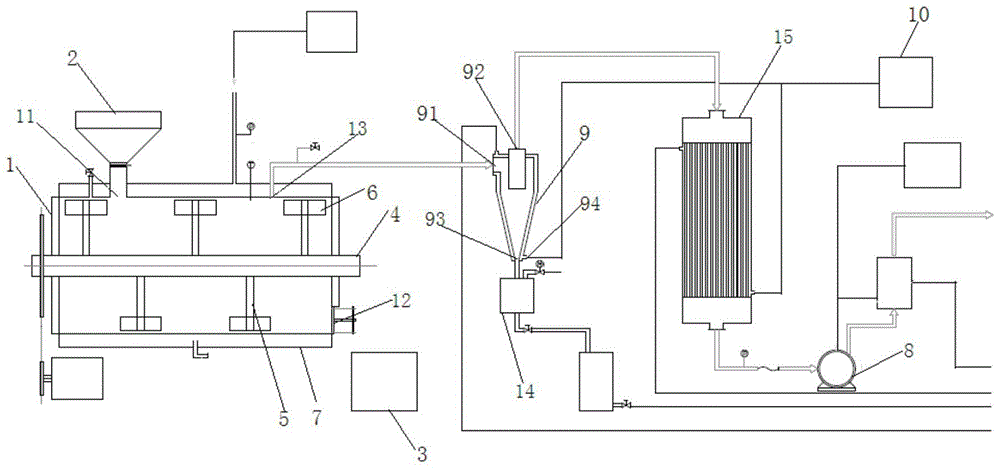

[0043] like figure 1 As shown, a kind of vacuum drying system provided in this embodiment includes

[0044] The furnace body 1 is arranged along the horizontal direction, and has a sealed cavity, a material inlet 11 for feeding and taking out materials, and a material outlet 12; and a first gas outlet 13 for the gas in the furnace body 1 to flow out;

[0045] The feeding device 2 is used to add materials into the cavity of the furnace body 1;

[0046] The material receiving device 3 is used to collect the dried material in the furnace body 1;

[0047] The vacuum device 8 is connected with the first gas outlet 13, and is used to maintain the required negative pressure environment in the cavity of the furnace body 1;

[0048] Stirring device for stirring and pulverizing the materials in the furnace body 1 in multiple directions;

[0049] The heating device is used to provide heat to the wall surface of the furnace body 1 and / or the stirring device, so that the cavity of the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com