Segmented combined type inner finned tube device for strengthening flow boiling heat exchange

A technology of segmented combination and boiling heat exchange, applied in tubular elements, heat transfer modification, heat exchange equipment, etc., can solve problems such as adverse effects, and achieve the effect of optimizing heat exchange performance, saving energy, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

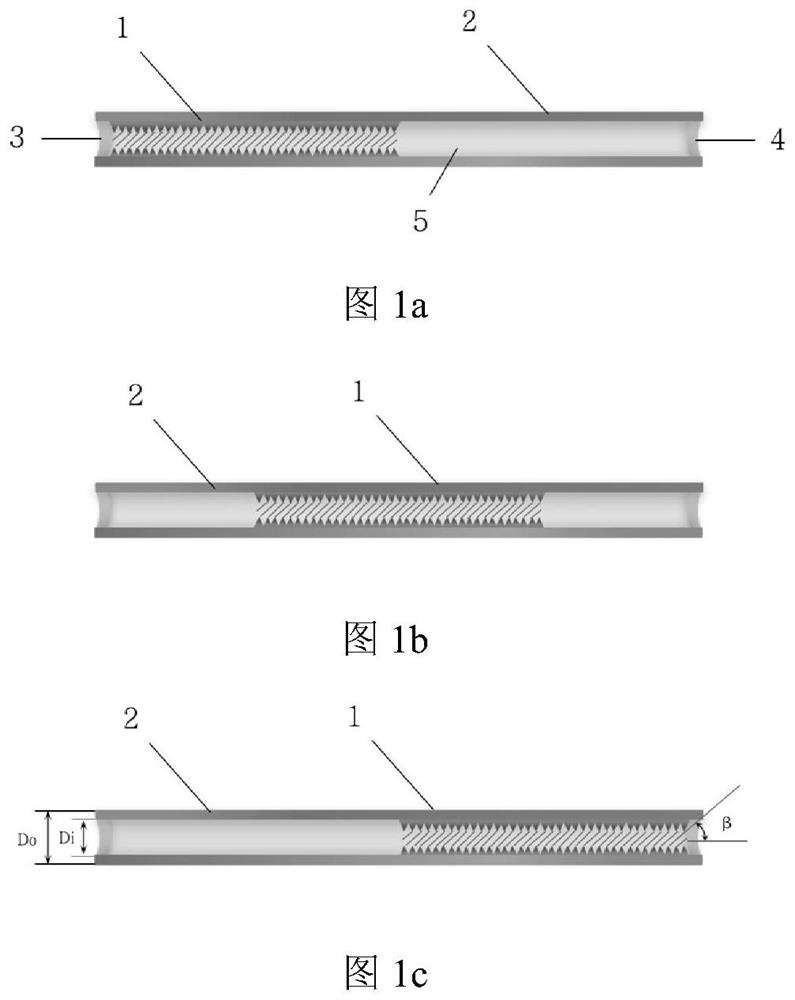

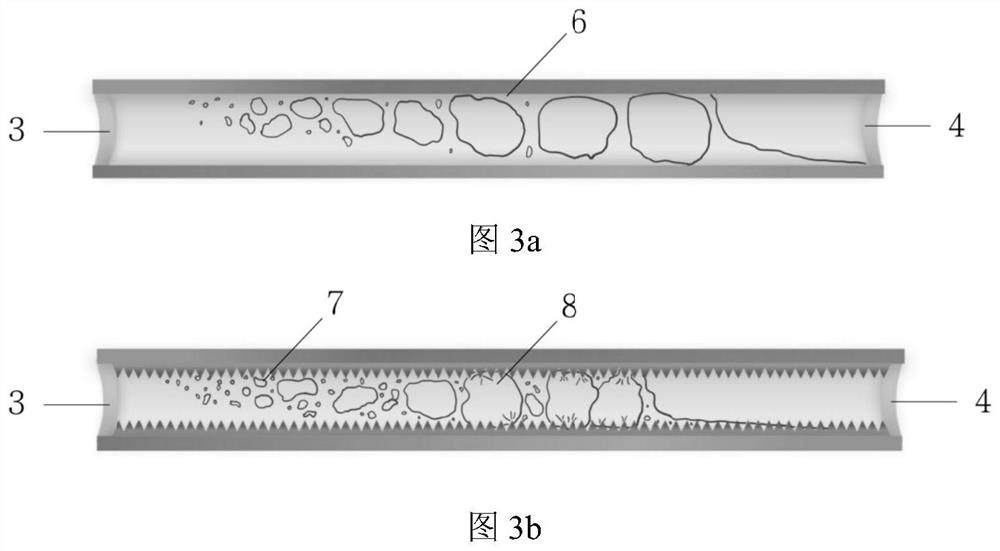

[0024] What this embodiment provides is a segmented combined finned tube device that enhances flow boiling heat exchange. The finned tube is divided into at least two sections, one of which is set as a threaded micro-finned tube 1 (referred to as a threaded tube), and the rest The sections are all set as smooth pipes 2, the inside of the finned tube is a gas-liquid circulation channel 5, one end is set as the fluid inlet 3 of the finned tube, and the other end is set as the fluid outlet 4;

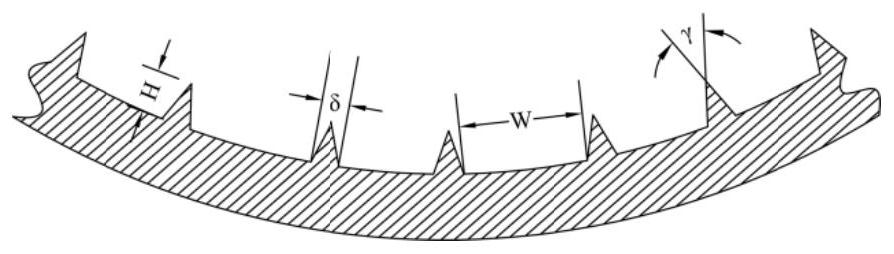

[0025] The threaded micro-finned pipe 1 and the smooth pipe 2 are coaxially arranged, and the cumulative length and inner and outer diameters are consistent. Using welding technology, the two pipes are sealed into one body according to the front and rear sections and the middle section. There are three types in total. type, such as Figure 1 as shown, figure 1 The finned tube in a is divided into two sections as a whole, and the section near the fluid inlet 3 is set as a threaded micro-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com