Experimental device for evaporating and post-evaporating thermotechnical hydraulic characteristics during in-tube flow boiling and evaporation judging method

An experimental device, thermal hydraulic technology, applied in the direction of material thermal development, etc., can solve the problems that endanger the safe and stable operation of the steam generator system, and the drastic change of the wall temperature of the heat transfer tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

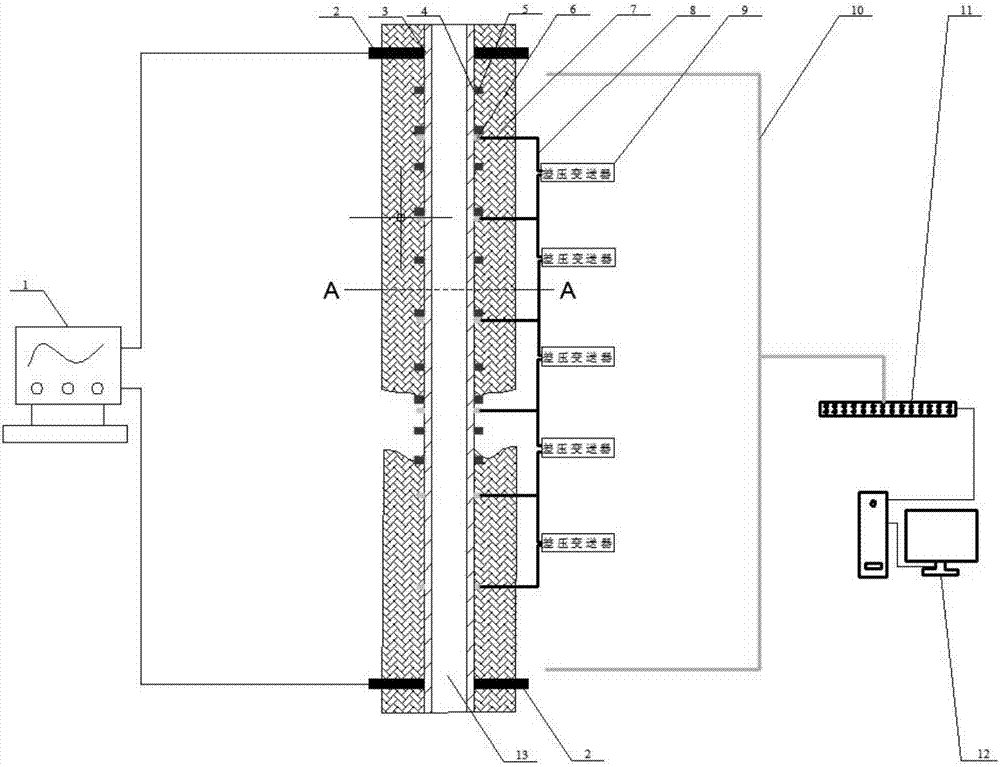

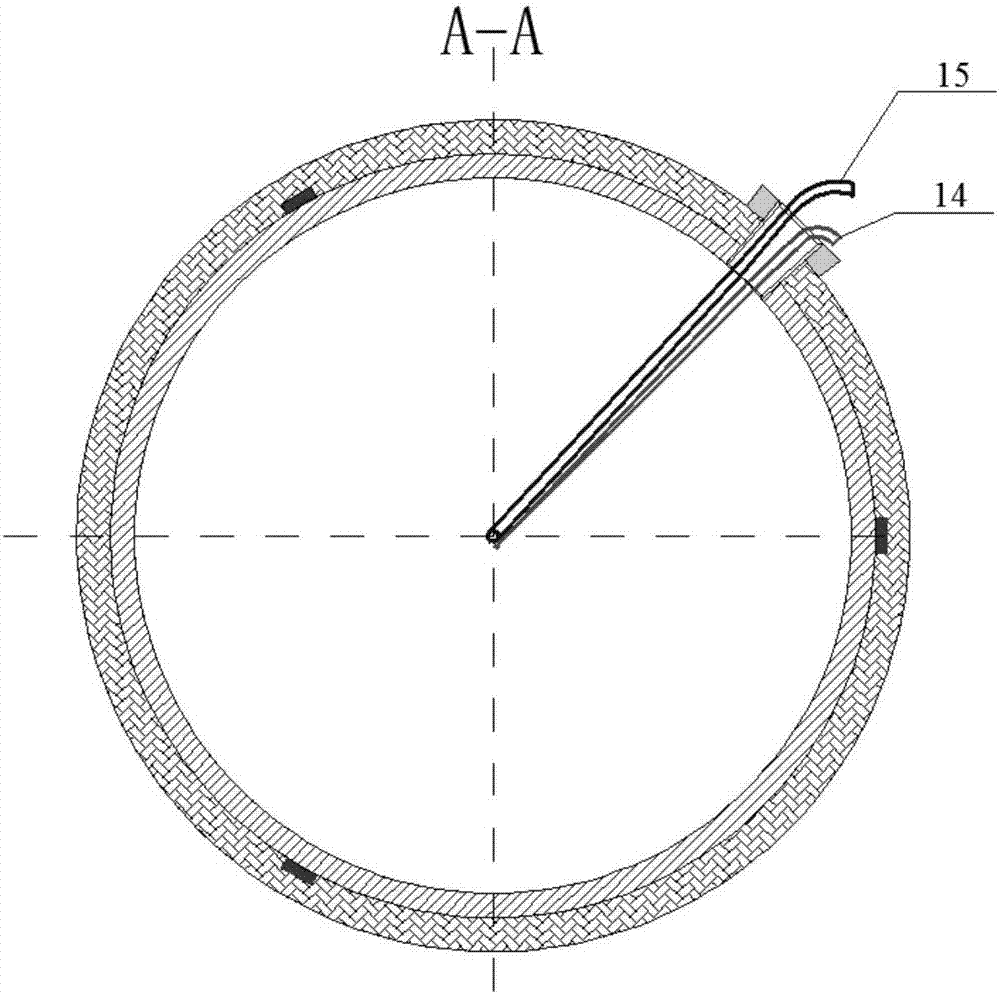

[0025] The experimental device for flow boiling evaporation in the tube and thermal hydraulic characteristics after evaporation includes a vertical tube experiment section, an electric heater and its control system 1, a heating electrode and a data acquisition system. Electrodes 2 are respectively installed at the upper and lower ends of the test section body of the vertical tube, and the electrodes are connected with electric heaters to heat the supercooled water flowing vertically upward in the test section. The outer wall of the experimental section is equipped with a thermal resistor 5 through high temperature glue 4, a pressure sensor 14 and an optical fiber probe 15 are installed in the experimental section, a measuring hole 6 is opened on the experimental section, and differential pressure tubes 8 are installed between adjacent measuring hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com