Ground simulative experiment device and method for micro-gravity flow boiling critical heat flux density

A technology of critical heat flux and boiling criticality, which is applied in the investigation stage/state change, etc., can solve the problems that the flow boiling simulation experiment data deviates from the application range, the simulation experiment method is not practical, and the critical experiment conditions are harsh. Wide operating range, simple installation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

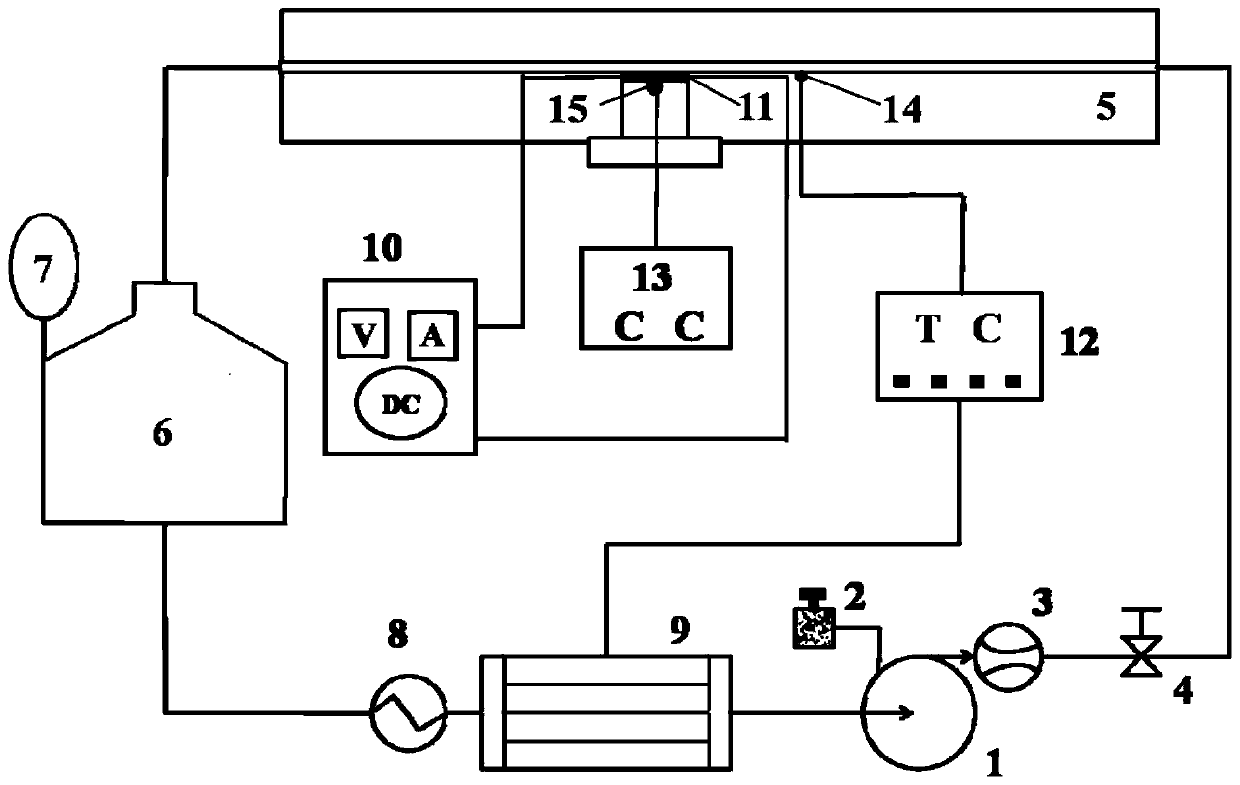

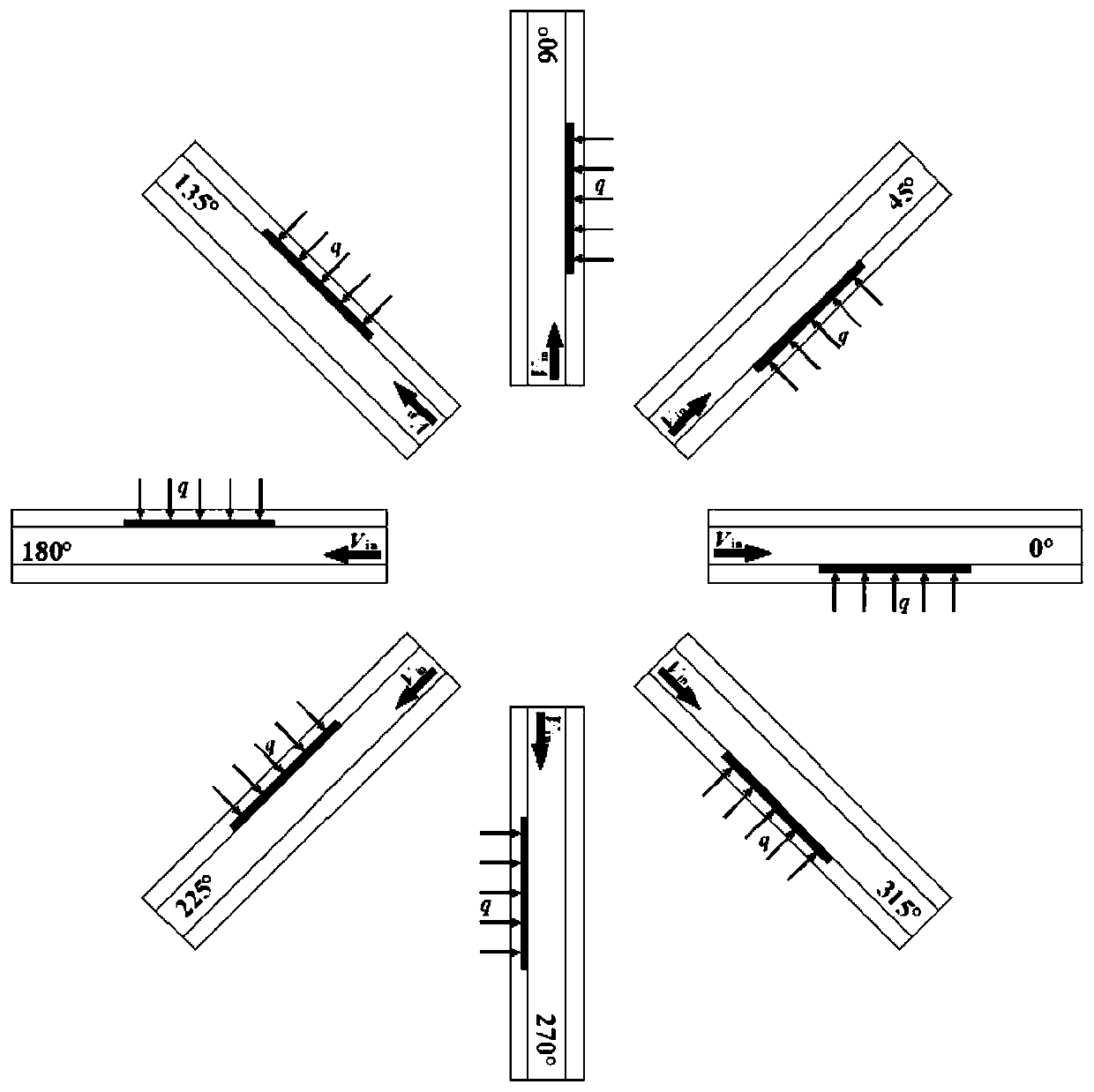

[0029] see figure 1 and figure 2 , a ground simulation experiment device of microgravity flow boiling critical heat flux density, comprising a test tube 5, the cross section of the test tube 5 is rectangular or circular, and the included angle between the test tube 5 and the horizontal plane is adjustable from 0 to 360° , during use, the angle between the test tube 5 and the horizontal plane is set to 0°, 45°, 90°, 135°, 180°, 225°, 270°, 315° or 360°, the inlet end of the test tube 5 Connect to the flow meter 3 through the flow regulating valve 4, the inlet end of the flow meter 3 is connected to the pump 1, the inlet end of the pump 1 is connected to the condenser 9, the inlet end of the condenser 9 is connected to the preheater 8, and the preheater 8 The inlet end of the buffer tank 6 is connected to the buffer tank 6 for storing the fluid medium, the inlet end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com