Compound gas hydrate generation accelerant and preparation method thereof

A gas hydrate and hydrate generation technology, applied in the direction of using atmospheric pressure to chemically change substances, gas fuels, chemical instruments and methods, etc., can solve the problems of low gas conversion efficiency, secondary pollution, difficult recovery, etc. , to achieve the effects of improving production efficiency, easy recycling, and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Based on 1000g of the mixed solution, weigh nano-graphene, dimethylene-1,2-bis(dodecyldimethylammonium bromide)-C 12-2-12 2Br -1 and distilled water, add the weighed nanographene into distilled water, turn on the stirrer at the same time, and stir at a speed of 400ppm, and the stirring time is 8min; the weighed dimethylene-1,2-bis(dec Dialkyldimethylammonium bromide)-C 12-2-12 2Br -1 Add it into the stirred liquid, and turn on the agitator again to stir at a high speed of 900ppm, and the stirring time is controlled at 40 minutes; finally, the stirred liquid is dispersed by ultrasonic waves, and the time is controlled at 30 minutes. The configured liquid package is ready for use.

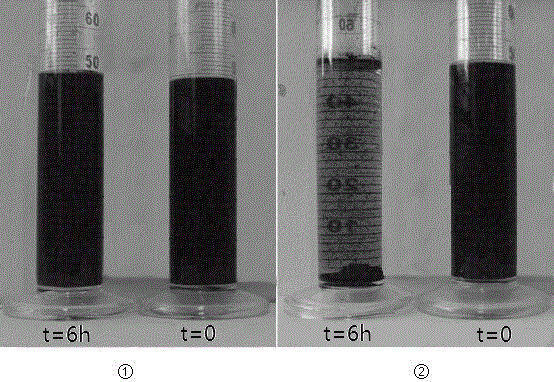

[0020] 200ml of the prepared liquid was added to a reaction kettle with a volume of 500ml, and the hydrate formation experiment was carried out at a temperature of 4°C, a pressure of 4MPa, and a rotation speed of 400rpm. The gas used in the experiment was CO 2 , the experimental results ...

Embodiment 2

[0022] Based on 1000g of the mixed solution, weigh nano-graphene, dimethylene-1,2-bis(dodecyldimethylammonium bromide)-C 12-2-12 2Br -1 and distilled water, add the weighed nanographene into distilled water, turn on the stirrer at the same time, and stir at a speed of 400ppm, and the stirring time is 8min; the weighed dimethylene-1,2-bis(dec Dialkyldimethylammonium bromide)-C 12-2-12 2Br -1 Add it into the stirred liquid, and turn on the agitator again to stir at a high speed of 900ppm, and the stirring time is controlled at 40 minutes; finally, the stirred liquid is dispersed by ultrasonic waves, and the time is controlled at 30 minutes. The configured liquid package is ready for use.

[0023] 200ml of the prepared liquid was added to a reaction kettle with a volume of 500ml, and the hydrate formation experiment was carried out at a temperature of 4°C, a pressure of 3.5MPa, and a rotation speed of 400rpm. The gas used in the experiment was CO 2 , the experimental result...

Embodiment 3

[0025] When preparing nanofluid, it is basically the same as Example 1, except that the mass fraction of nano-graphene is 0.12%, and dimethylene-1,2-bis(dodecyldimethylammonium bromide)-C 12-2-12. 2Br -1 The mass fraction is 0.08%, and water is the balance.

[0026] 200ml of the prepared liquid was added to a reaction kettle with a volume of 500ml, and the hydrate formation experiment was carried out at a temperature of 4°C, a pressure of 3MPa, and a rotation speed of 400rpm. The gas used in the experiment was CO 2 , the experimental results show that hydrate crystal nuclei appeared in the window after 92s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com