Method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid

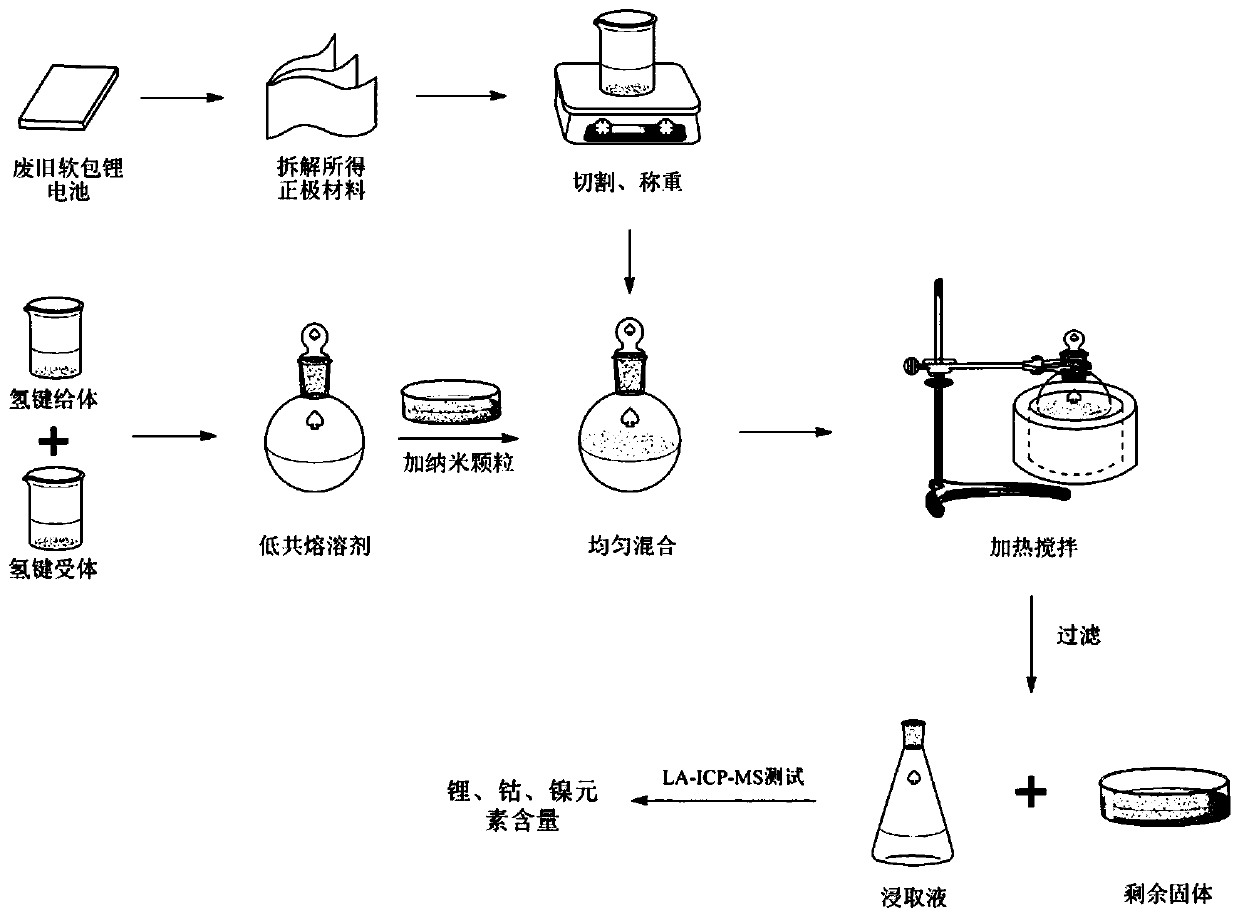

A deep eutectic solvent and lithium-ion battery technology, which is applied in secondary batteries, battery recycling, recycling technology, etc., can solve problems such as non-recyclability, environmental hazards, and difficult operation, and achieve a wide range of raw material sources, The effect of short time consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 20.0g (0.333mol) of urea (0.333mol) and 15.5g (0.111mol) of choline chloride into a reactor equipped with magnetic stirring, mix at room temperature, heat to 60°C and stir for 0.5 hours at a stirring speed of 600r / min, cool to room temperature after reaction finishes, obtain urea / choline chloride deep eutectic solvent;

[0026] (2) Add 3.55mg (0.01wt.%) of sodium dodecylbenzenesulfonate to the deep eutectic solvent obtained in step (1), heat to 60°C, stir and mix evenly, then add 0.071g of aluminum oxide (0.2wt.%), and stirred at 60°C for 1 hour, and the stirring speed was 600r / min to obtain a mixed solution;

[0027] (3) Put the mixed solution obtained in step (2) into an ultrasonic cell pulverizer, and ultrasonically disperse for 1 hour at 25° C. to obtain urea / choline chloride deep eutectic solvent nanofluid;

[0028] (4) After fully discharging the waste nickel-cobalt lithium manganese oxide battery, peel off the shell, disassemble the battery to obtain th...

Embodiment 2

[0032] (1) Add 30.0g (0.333mol) of oxalic acid (0.333mol) and 13.0g (0.111mol) of betaine to a reactor equipped with magnetic stirring, mix at room temperature, heat to 60°C and stir for 1 hour at a stirring speed of 800r / min , cool to room temperature after the reaction finishes, obtain oxalic acid / choline chloride deep eutectic solvent;

[0033] (2) Add 12.9mg (0.03wt.%) of sodium lauryl sulfate to the deep eutectic solvent obtained in step (1), stir and mix after heating to 60°C, then add 0.215g (0.5wt.%) of silicon dioxide .%), and stirred at 60° C. for 1.5 hours at a stirring speed of 800 r / min to obtain a mixed solution;

[0034] (3) Put the mixed solution obtained in step (2) into an ultrasonic cell pulverizer. Ultrasonic dispersion at 25°C for 1 hour to obtain oxalic acid / betaine deep eutectic solvent nanofluid;

[0035] (4) After fully discharging the waste nickel-cobalt lithium manganese oxide battery, peel off the shell, disassemble the battery to obtain the waste...

Embodiment 3

[0039] (1) Add 20.7g (0.333mol) of ethylene glycol (0.333mol) and 15.5g (0.111mol) of choline chloride into a reactor equipped with magnetic stirring, mix at room temperature, heat to 80°C and stir for 1.5 hours. Be 600r / min, be cooled to room temperature after reaction finishes, obtain ethylene glycol / choline chloride deep eutectic solvent;

[0040] (2) Add polyvinyl alcohol 18.1mg (0.05wt.%) to the deep eutectic solvent obtained in step (1), stir and mix after heating to 80°C, then add titanium dioxide 0.362g (1.0wt.%), and Stir at 80°C for 1 hour at a stirring speed of 600r / min to obtain a mixed solution;

[0041] (3) Put the mixed solution obtained in step (2) into an ultrasonic cell pulverizer. Ultrasonic dispersion at 25°C for 1.5 hours to obtain ethylene glycol / choline chloride deep eutectic solvent nanofluid;

[0042] (4) After fully discharging the waste nickel-cobalt lithium manganese oxide battery, peel off the shell, disassemble the battery to obtain the waste po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com