A method for preparing carbon nanofluid

a carbon nanotube and fluid technology, applied in the field of carbon nanotube preparation, can solve the problems of low thermal conductivity, difficult to evenly disperse carbon nanotubes into fluids, and strong and flexible carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Nanofluid A (Carbon Nanotubes / Ethylene Glycol)

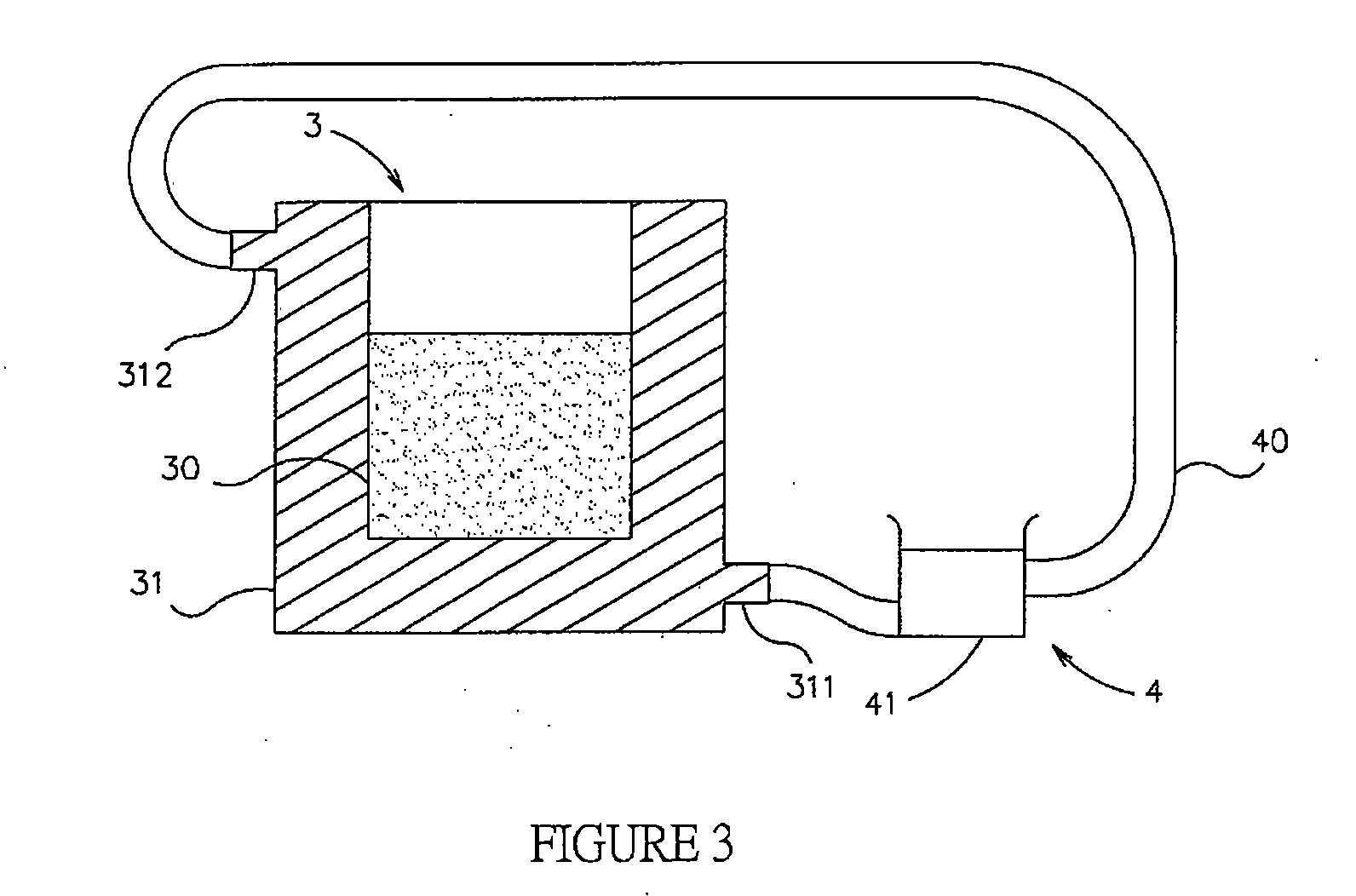

[0035] The nanofluid A was prepared by dispersing multiple walled carbon nanotubes in ethylene glycol. No surfactant was added to the nanofluid A. And the carbon nanotubes were combined with and dispersed in ethylene glycol through an ultrasonication operation at 600 W for approximately one hour. During the ultrasonication operation, a cooling operation was applied using a dual tube heat exchanger as shown in FIG. 2 for cooling the nanofluid A during the ultrasonication operation performed by an ultrasonic homogenizer.

[0036] Next, the nanofluid A was subjected to thermal conductivity measurement as described above. As listed in Table 1 below, the thermal conductivity (represented by k value) was increased by 12.4% at a volume fraction of 0.01 (1 vol. %) for the carbon nanotubes / ethylene glycol suspensions as compared with ethylene glycol only. Therefore, small amount of carbon nanotubes dispersed according to the present invention resu...

example 2

Nanofluid B (Carbon Nanotubes / Water)

[0037] The nanofluid B was prepared by dispersing multiple walled carbon nanotubes in the water. No surfactant was added to the nanofluid B. And the carbon nanotubes were combined with and dispersed in the water through an ultrasonication operation at 600 W for approximately one hour. During the ultrasonication operation, a cooling operation was applied using a dual tube heat exchanger as shown in FIG. 2 for cooling the nanofluid B during the ultrasonication operation performed by an ultrasonic homogenizer.

[0038] Next, the nanofluid B was subjected to thermal conductivity measurement as described above. As listed in Table 2 below, the thermal conductivity was increased by 17.8% at a volume fraction of 0.015 (1.5 vol. %) for the carbon nanotubes / water suspensions as compared with water only. Therefore, small amount of carbon nanotubes dispersed according to the present invention resulted in a significant increase in the thermal conductivity of th...

example 3

Nanofluid C (Carbon Nanotubes / Synthetic Engine Oil)

[0039] The nanofluid C was prepared by dispersing multiple walled carbon nanotubes in the synthetic engine oil. N-hydroxysuccinimide (NHS) was added to the nanofluid C. And the carbon nanotubes were combined with and dispersed in the synthetic engine oil through an ultrasonication operation at 600 W for approximately one hour. During the ultrasonication operation, a cooling operation was applied using a dual tube heat exchanger as shown in FIG. 2 for cooling the nanofluid C during the ultrasonication operation performed by an ultrasonic homogenizer.

[0040] Next, the nanofluid C was subjected to thermal conductivity measurement as described above. As listed in Table 3 below, the thermal conductivity was increased by 30.3% at a volume fraction of 0.02 (2.0 vol. %) for the carbon nanotubes / synthetic engine oil suspensions as compared with oil only. Therefore, small amount of carbon nanotubes dispersed according to the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com