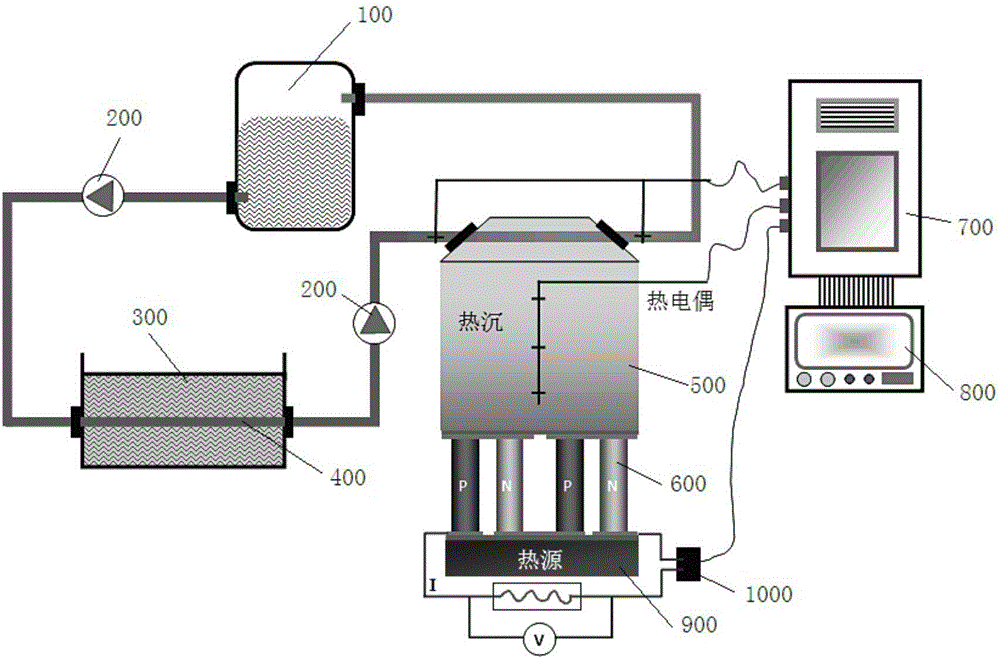

System and method for synchronously testing nanofluid heat transfer coefficient and influence rule thereof on power generation efficiency of thermoelectric generation system

A technology of nanofluid and heat transfer coefficient, applied in the system field, can solve problems such as errors, achieve the effects of ensuring accuracy, reducing measurement errors, and improving measurement accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

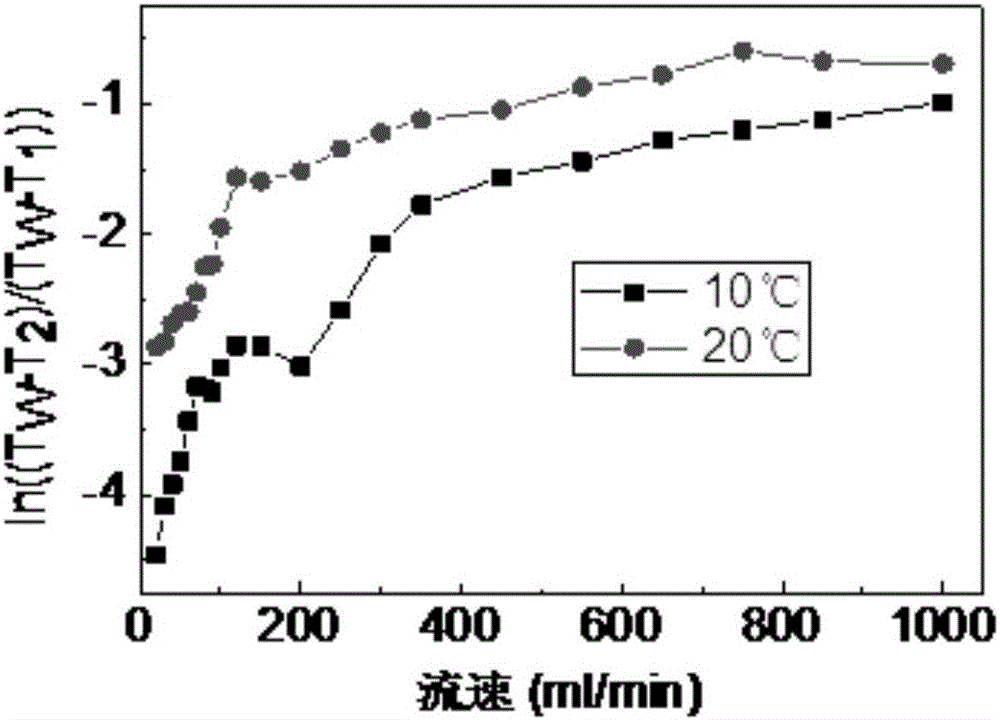

[0034] Disperse 0.5g of nano-alumina (VK-L06, 30+5nm) in 500ml of deionized water, adjust the pH to 8 with 0.05mol / L NaOH solution, then add 0.5g of sodium dodecylbenzenesulfonate (SDBS), Ultrasonic dispersion was carried out for 1 hour, and after standing for 14.5 hours, ultrasonic wave was used for 0.5 hour to prepare nano-alumina-water nanofluid system. Control the temperature of the nanofluid in the liquid storage tank to 60°C, set the temperature of the cold water bath to 10°C and 20°C successively, and measure the T 1 , T 2 , T w The temperature at the place, according to the formula ln[(T w -T 2 ) / (T w -T 1 )] Calculate the relationship between the measured temperature and the flow velocity at the three points, and then substitute the mass flow velocity, specific heat capacity and related dimensions, according to h=-m v C p ln[(T w -T 2 ) / (T w -T 1 )] / 2rπΔL can be obtained nanofluid enhanced heat transfer coefficient, the specific results are as follows fig...

Embodiment 2

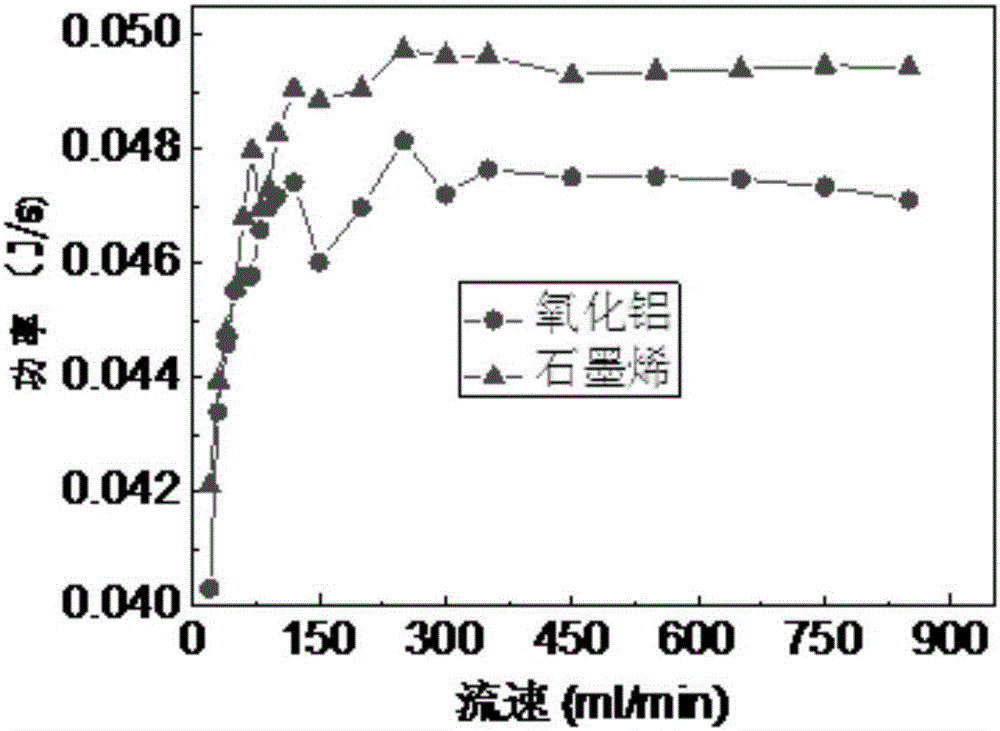

[0036] 0.80 g of graphene oxide was added to 800 ml of deionized water, ultrasonicated for 1 h, and then stirred at a rotational speed of 1000 r / min for 1.5 h to obtain a graphene oxide-water system nanofluid. Disperse 0.5g of nano-alumina (VK-L06, 30+5nm) in 500ml of deionized water, adjust the pH to 8 with 0.05mol / L NaOH solution, and then add 0.5g of sodium dodecylbenzenesulfonate (SDBS) , ultrasonically dispersed for 1 h, and then ultrasonically 0.5 h after standing still for 14.5 h to obtain a nano-alumina-water nanofluid system. The temperature of the nanofluid in the liquid storage tank is controlled to be 60°C, the temperature of the cold water bath is set to 10°C, and the temperature of the hot end of the thermoelectric device is set to 100°C. The thermoelectric device adopts 48 pairs of bismuth telluride-based frame structure thermoelectric devices with an internal resistance of 0.2342Ω. Measure the thermoelectric voltage of the thermoelectric device and the current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com