Preparation method of nanofluid cooling liquid and nanofluid cooling liquid prepared by same

A nano-fluid and coolant technology, which is applied in the field of engine coolant, can solve the problems of difficult industrial production, high equipment requirements, and high cost, and achieve good stability, narrow distribution range, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

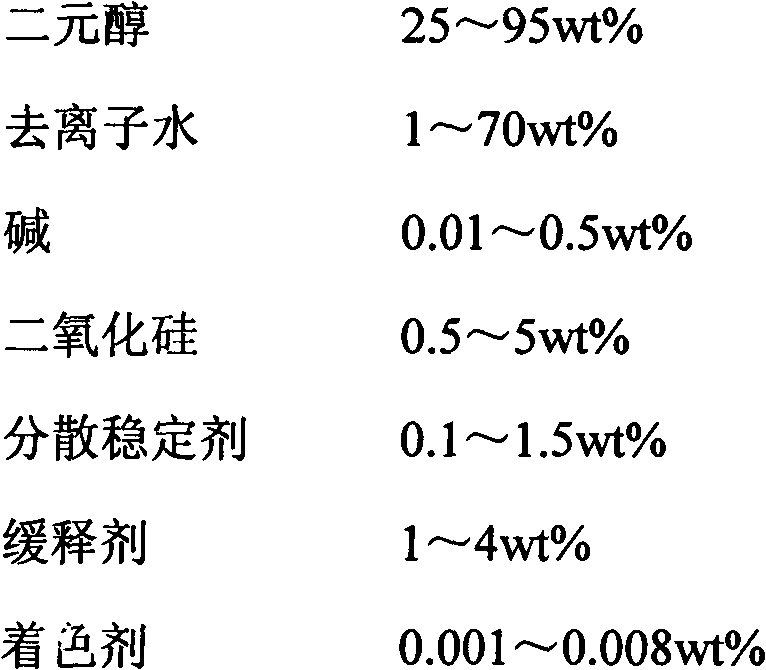

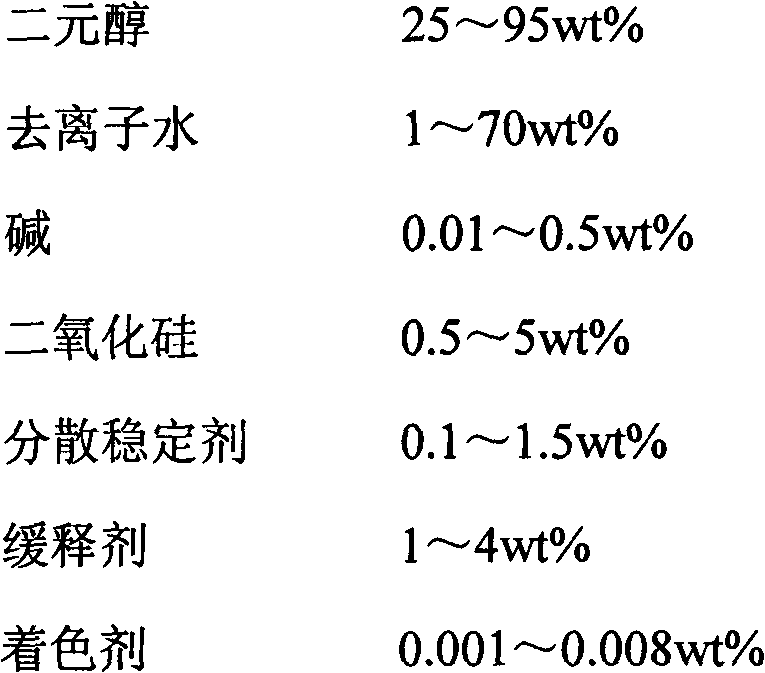

Method used

Image

Examples

Embodiment 1

[0018] Take 450kg of ethylene glycol, 550kg of deionized water, and 0.1kg of sodium hydroxide. Stir and mix uniformly in the reactor to obtain the coolant base liquid; heat the coolant base liquid to 60℃, and slowly add 100kg of ethyl silicate to it , The reaction was stirred for 12 hours; the reaction solution was heated to 85°C, the ethanol produced by the reaction was distilled off, and then cooled to room temperature to obtain a nanofluid containing silica nanoparticles; a non-ionic siloxane coupling agent was added to the nanofluid 7.5kg, stir for 2 hours and mix evenly; then add 20kg of organic acid corrosion inhibitor to the mixed solution, stir for 2 hours and mix evenly; add 0.02kg of light fast blue colorant to the mixed solution, stir for 1 hour and mix evenly to obtain Nano-fluid coolant for silica nanoparticles.

Embodiment 2

[0020] Take 350kg of ethylene glycol, 150kg of propylene glycol, 500kg of deionized water, 0.1kg of sodium hydroxide, and 0.1kg of ammonia water, stir and mix uniformly in the reactor to obtain the coolant base liquid; raise the coolant base liquid to 50°C and slowly add to it Add 150kg of ethyl silicate, stir and react for 24 hours; raise the temperature of the reaction solution to 95°C, distill off the ethanol produced by the reaction, and then cool to room temperature to obtain a nanofluid containing silica nanoparticles; add poly to the nanofluid 10kg of oxyethylene-polyoxypropylene block polymer, stir for 2 hours and mix well; then add 40kg of inorganic corrosion inhibitor to the mixture, stir for 2 hours and mix well; add 0.08kg of fluorescent yellow colorant to the mixture, stir for 1 Mix evenly within hours to obtain a nanofluid coolant containing silica nanoparticles.

Embodiment 3

[0022] Take 300 kg of ethylene glycol, 600 kg of propylene glycol, 100 kg of deionized water, 0.3 kg of sodium hydroxide, and 0.2 kg of potassium hydroxide. Stir and mix in the reactor to obtain the coolant base liquid; heat the coolant base liquid to 40°C, Among them, 200kg of ethyl silicate was slowly added, and the reaction was stirred for 24 hours; the reaction solution was heated to 80°C, the ethanol produced by the reaction was distilled off, and then cooled to room temperature to obtain a nanofluid containing silica nanoparticles; into the nanofluid Add 5kg of polyethylene glycol, stir for 2 hours and mix evenly; then add 30kg of inorganic corrosion inhibitor to the mixed solution, stir for 2 hours and mix evenly; add 0.04kg of cherry red colorant to the mixed solution, stir for 1 hour and mix evenly to obtain Nanofluid cooling liquid containing silica nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com