Method for developing hot dry rock geothermal resources through using gravity drainage technology

A hot dry rock technology, which is applied in the field of developing hot dry rock geothermal resources by gravity drainage, can solve problems that have not been raised, and achieve the effects of compact rock, reduced drilling costs, production and operation costs, and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

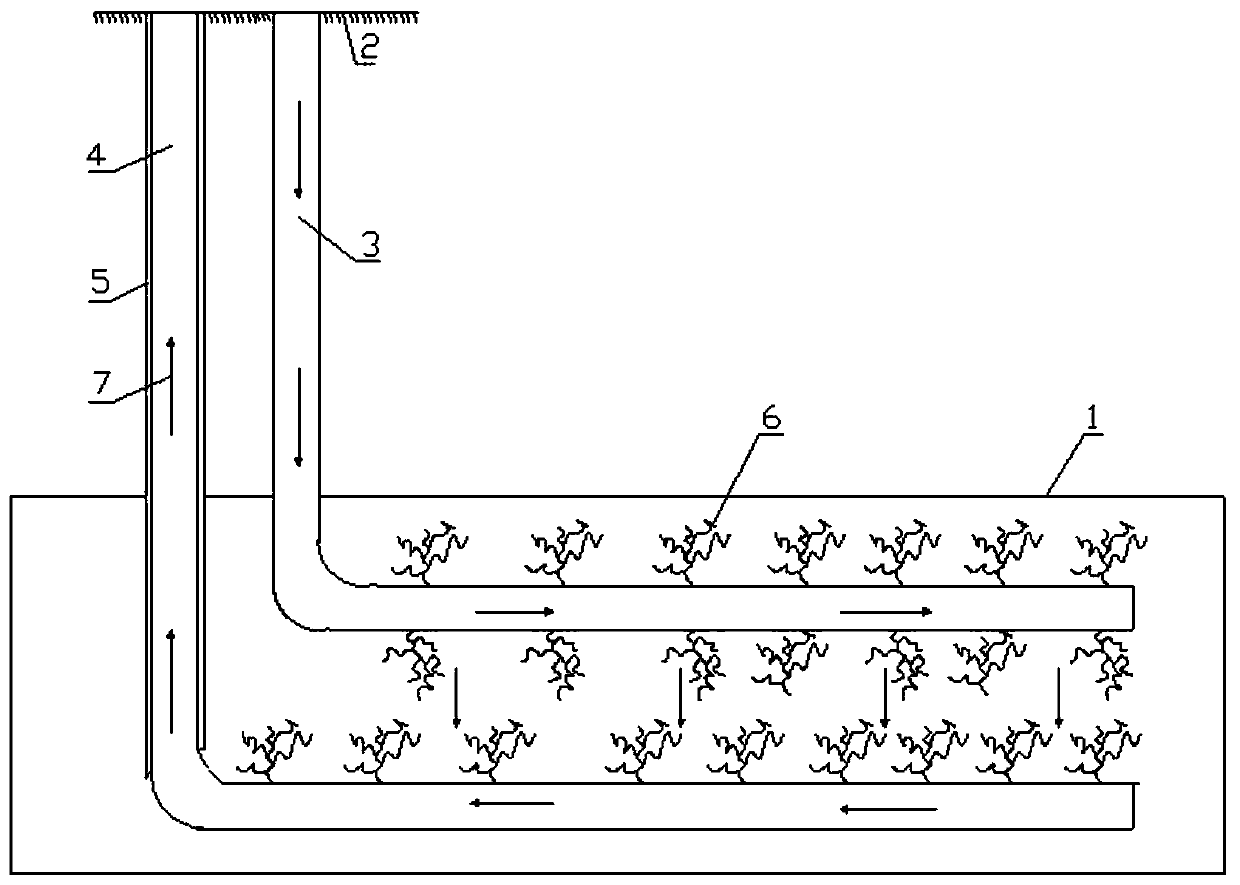

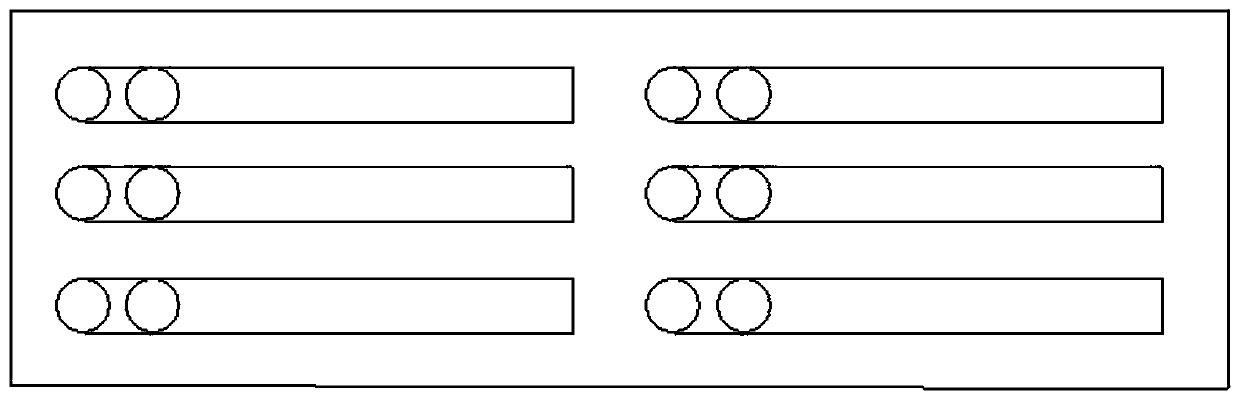

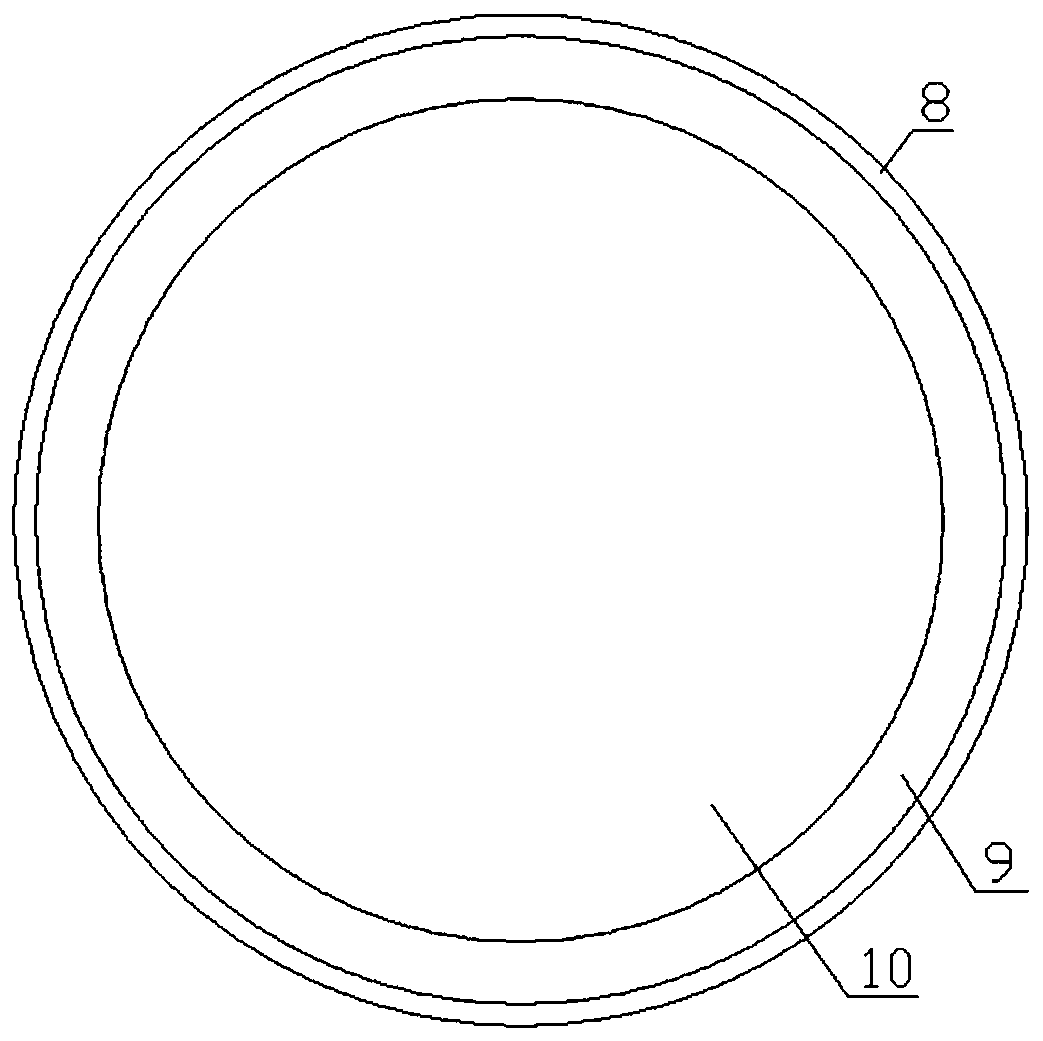

[0048] Such as figure 1 and figure 2 As shown, the injection well 3 and the production well 4 are two horizontal wells, and they are parallel, and the vertical distance of the horizontal section is 7 meters. The horizontal distance between each pair of injection and production wells is 50m, and the length of the horizontal section is 750m. The injection pipeline of the vertical well section of the production well is equipped with a wellbore insulation layer. For details of the structure, see image 3 . This design is suitable for hot dry rock formations with a temperature of 150-350°C. The number of cycles increases and heat loss is reduced.

[0049] The use of the insulation layer can ensure that the produced liquid reduces heat loss in the vertical well section, and the injection well pipeline does not need to add an insulation layer, so that the injected fluid can fully exchange heat with the formation. In the horizontal section of the injection well, it is considered...

Embodiment 2

[0051] The injection well 3 and the production well 4 are two horizontal wells, and they are parallel, and the vertical distance of the horizontal section is 5 meters. The horizontal spacing of each pair of injection-production wells is 30m, and the length of the horizontal section is 1000m. The injection pipeline of the vertical well section of the production well is equipped with a wellbore insulation layer. For details of the structure, see image 3 . This design is suitable for hot dry rock formations with a temperature of 200-500°C. The number of cycles increases and heat loss is reduced.

[0052] The use of the insulation layer can ensure that the produced liquid reduces heat loss in the vertical well section, and the injection well pipeline does not need to add an insulation layer, so that the injected fluid can fully exchange heat with the formation. In the horizontal section of the injection well, it is considered to run the injected fluid distribution string to en...

Embodiment 3

[0053] Embodiment 3. A method of utilizing gravity drainage to integrally develop hot dry rock geothermal resources according to the present invention.

[0054] Such as figure 1 and figure 2 As shown, the injection well 3 and the production well 4 are two horizontal wells, which are parallel, and the vertical distance between the horizontal sections is 5 meters. The horizontal spacing of each pair of injection-production wells is 80m, and the length of the horizontal section is 1500m. The injection pipeline of the vertical well section of the production well is equipped with a wellbore insulation layer. For details of the structure, see image 3 . This design is suitable for hot dry rock formations with a temperature of 350-550°C. Cycle times are reduced and heat transfer is more efficient.

[0055] Based on the data of various embodiments, it can be known that the method for the overall development of hot dry rock geothermal resources by gravity drainage according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com