Remained small coal pillar comprehensive mechanized coal mining supporting structure and construction method

A comprehensive mechanization and support structure technology, applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve problems such as heavy maintenance workload, air leakage in gobs, roof collapse, etc., and achieve reduced maintenance costs and universal adaptability , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments, which do not depart from the scope of the present invention, and among them The description and the drawings are essentially for the purpose of description, rather than limiting the present invention.

[0030] The present invention will be described in detail below with reference to the drawings and specific embodiments.

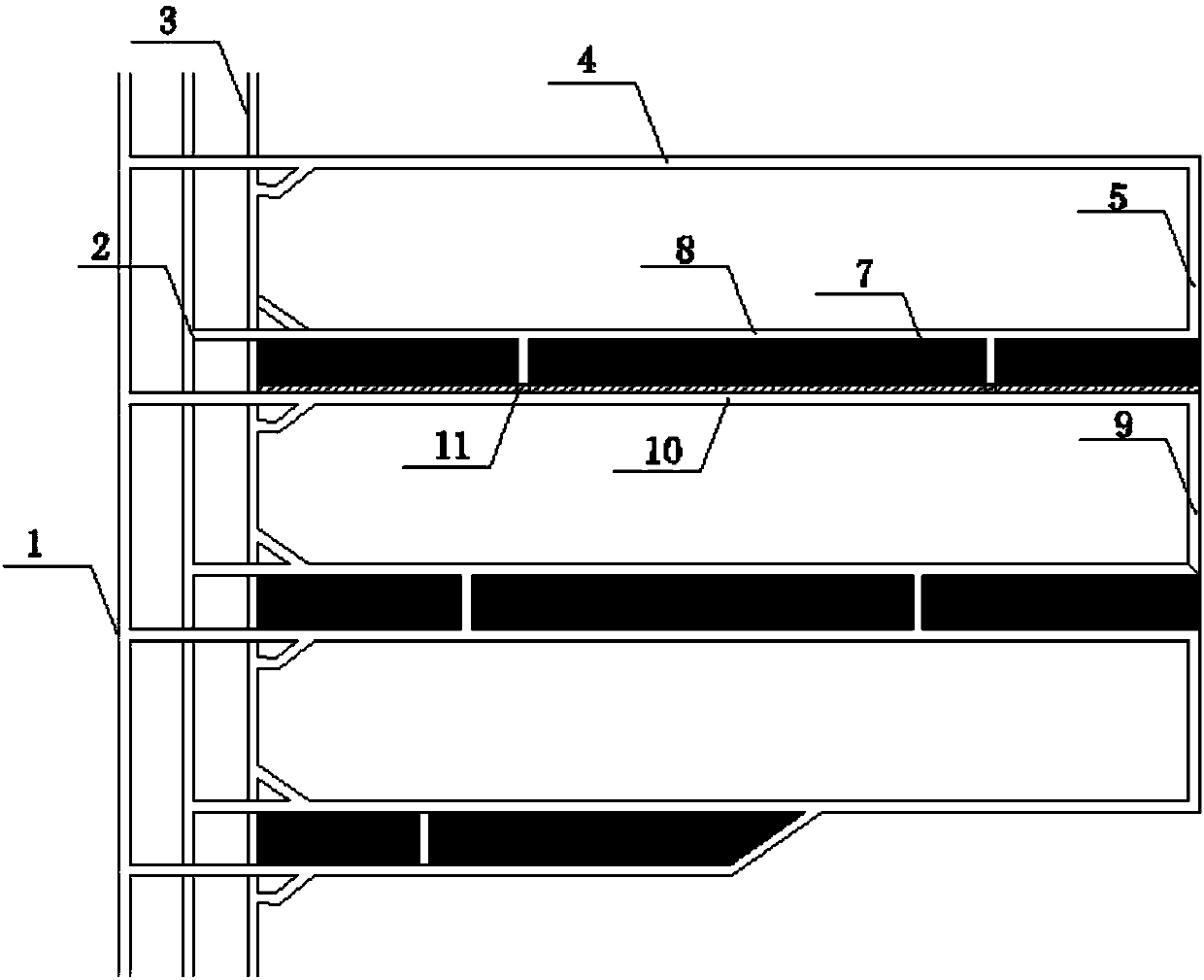

[0031] Such as figure 1 As shown, a comprehensive mechanized coal mining support structure with small coal pillars includes a narrow coal pillar 7 arranged between the current working face 5 and an adjacent mining face 9, and one side of the narrow coal pillar 7 is provided with a filling Body 11; the current working face 5 is provided with a roof pre-splitting and cutting line; the two sides of the current working f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com