Long-wall working face coal pillar-free mining method

A mining method and working face technology, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problem of uncoordinated roadside support and surrounding rock deformation, less application of active support technology, and lack of systematic support design, etc. problems, to achieve the effect of high mining rate and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

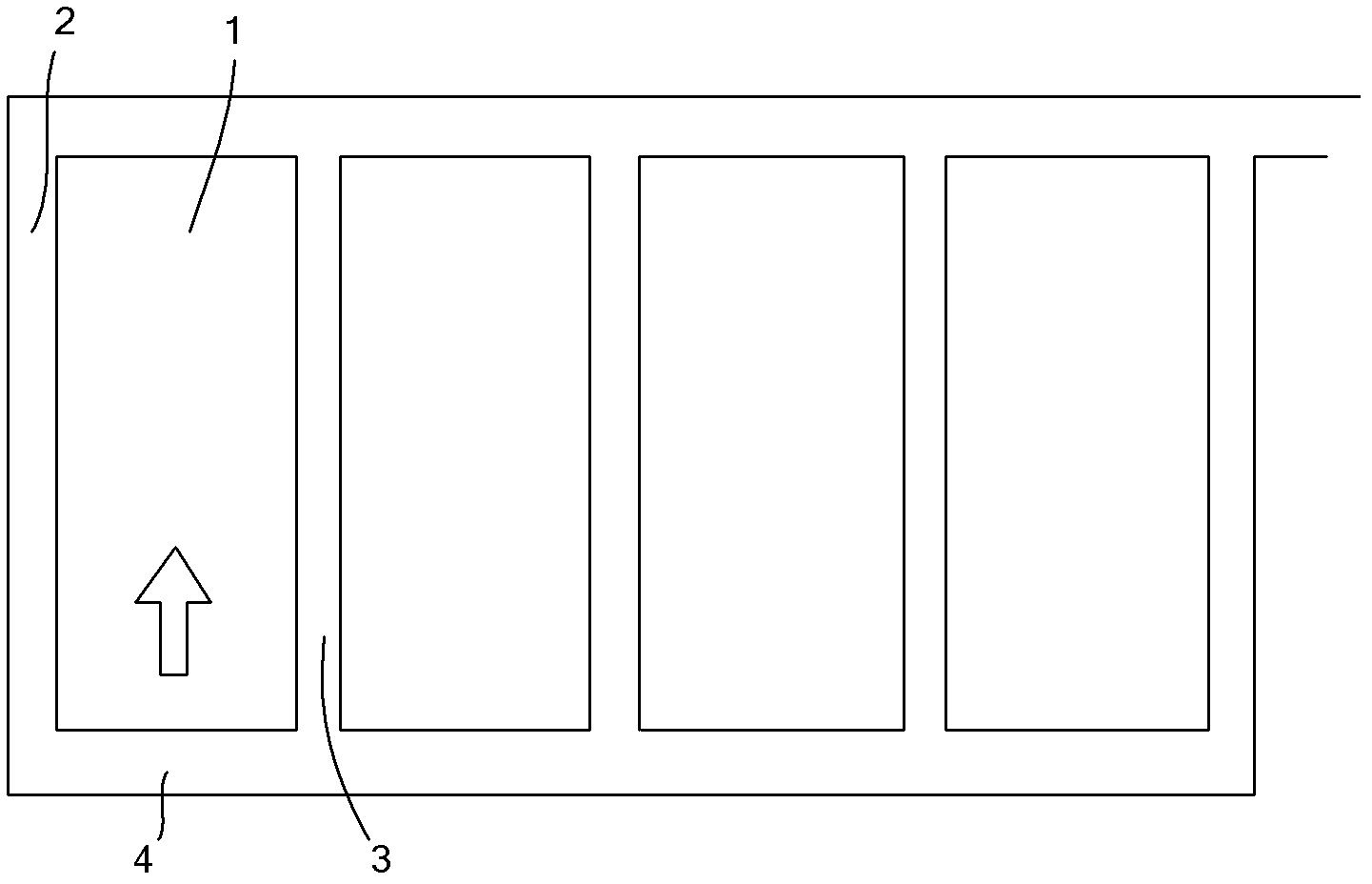

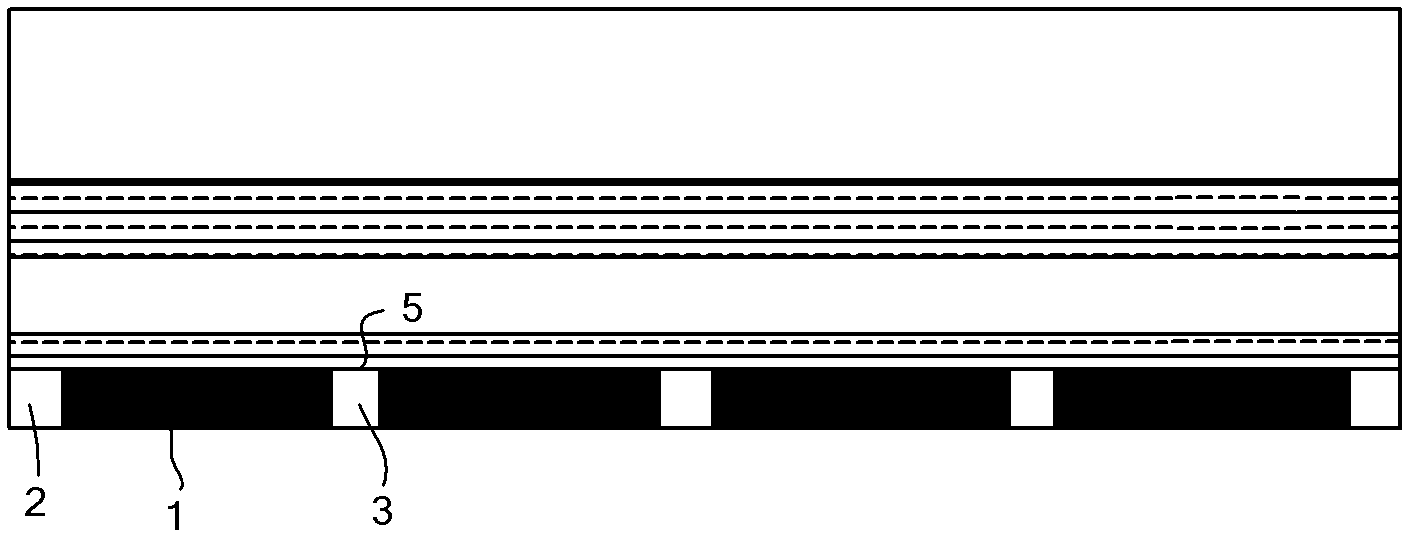

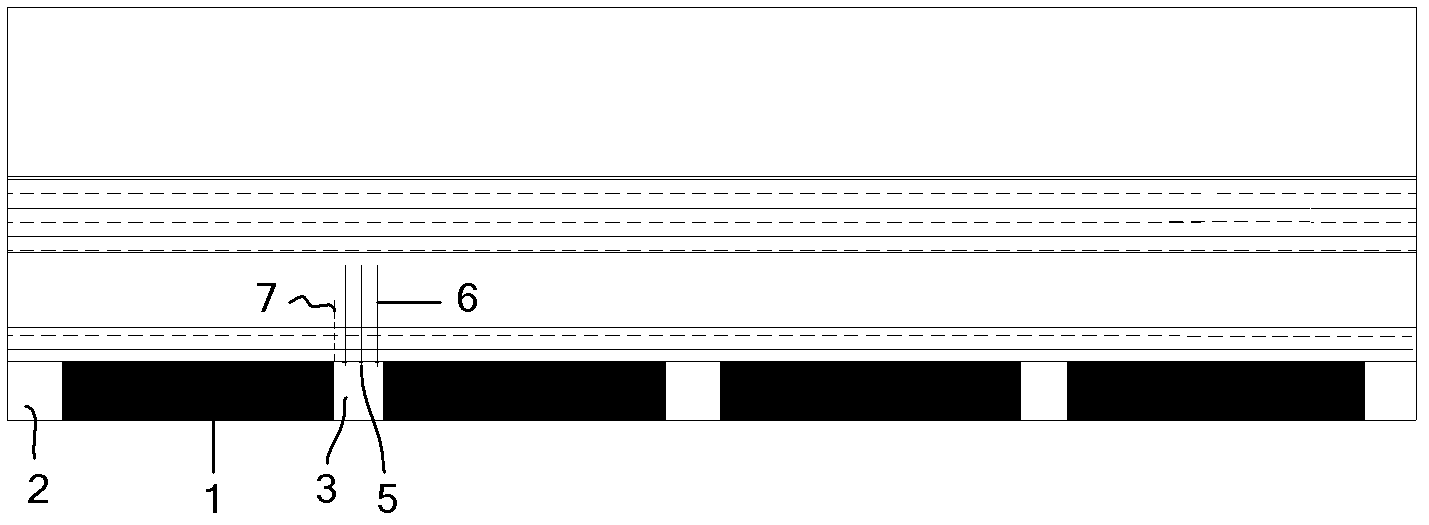

[0029] The coal pillar-free mining method adopted in the present invention firstly needs to form the first mining face. like figure 1 and figure 2 As shown, the method of forming the first mining face 1 is the same as the existing method. The first mining position is established on the edge of the coal seam mining. At this position, two parallel roadways 2, 3 and two The parallel roadways 2 and 3 are connected through the roadway 4 at the tail. The roadway 2 near the edge is the up-going roadway, the roadway 3 close to the continuing mining face is the down-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com