Continuous coal-mining technology for strip mine

A process method and open-pit mining technology, which is applied in open-pit mining, earth drilling, special mining, etc., can solve problems such as insufficient flexibility, troublesome relocation, and no continuous coal mining, so as to improve the recovery rate, Effect of reducing environmental pollution and increasing coal mining rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

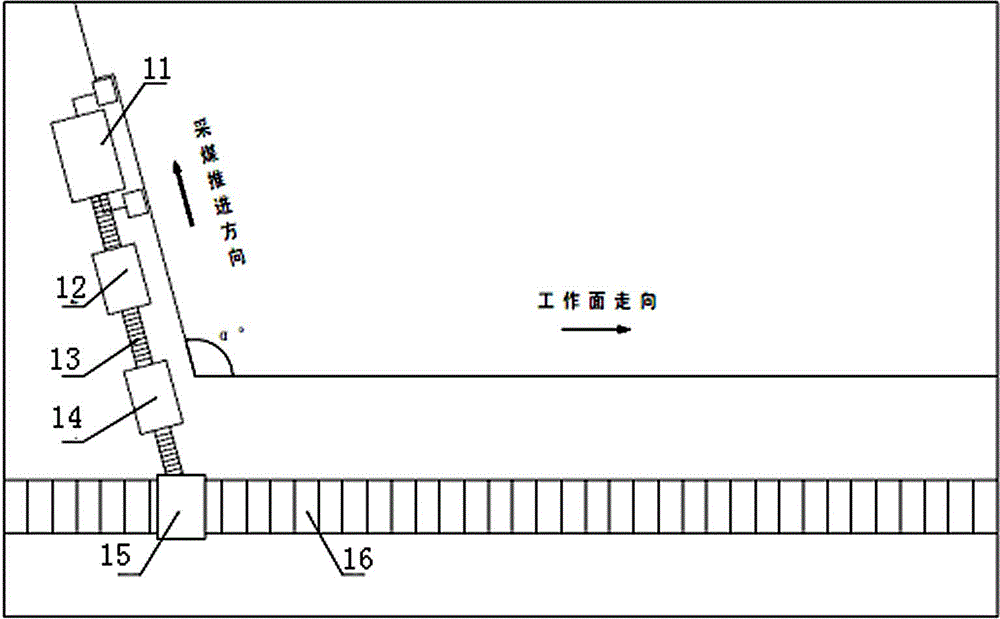

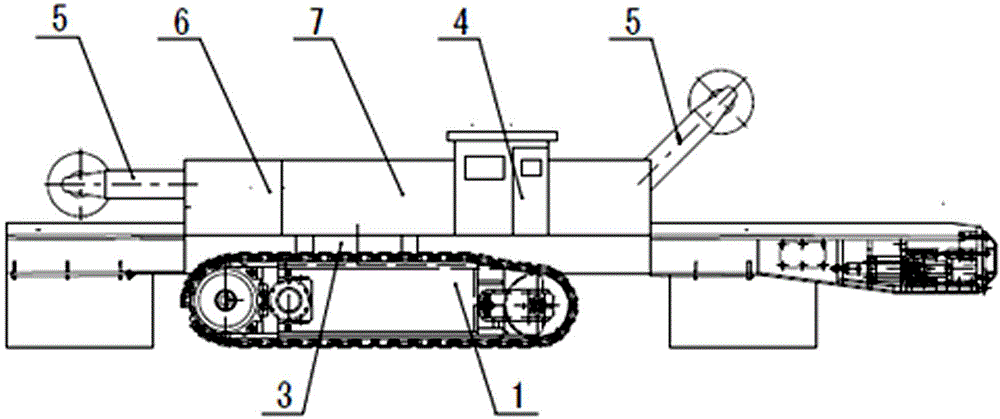

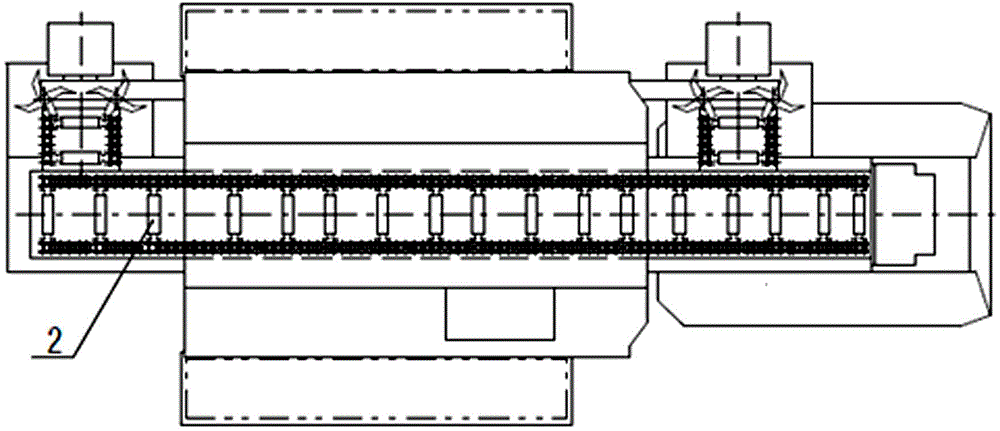

[0035] A continuous coal mining process in an open-pit mine. The equipment used includes a crawler-type double-drum shearer 11, a scraper-type continuous transport unit, a discharge trolley 15, and a working face belt conveyor 16. The scraper-type continuous transport unit consists of Crawler type crusher 14, bridge type reloader 13, crawler type reloader 12 are formed.

[0036]The working face belt conveyor 16 is arranged along the direction of the working face, and the crawler type double-drum shearer 11, the crawler type reloader 12, the bridge type reloader 13, and the crawler type crusher 14 are arranged along the direction of the working face. Arranged according to the coal mining advancing direction, the included angle between the coal mining advancing direction and the direction of the working face is greater than 90°.

[0037] The working method is that the crawler-type double-drum shearer 1 moves back and forth in both directions along the coal mining advancement dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com