Composite chlorination furnace for titanium tetrachloride production

A technology of titanium tetrachloride and chlorination furnace, applied in titanium tetrachloride, titanium halide and other directions, can solve the problems of inability to reflect resource advantages, difficult to recover salt, and inability to greatly increase production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

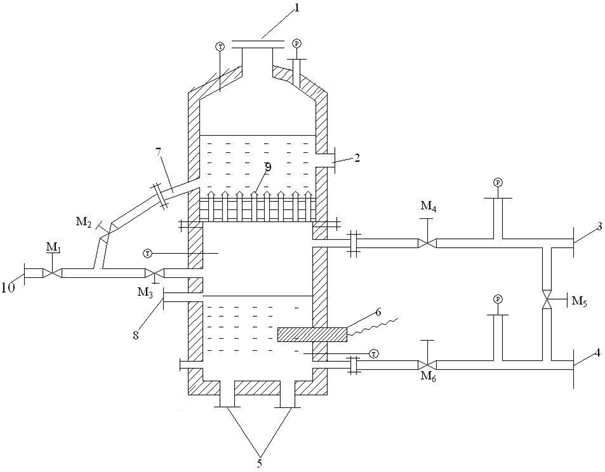

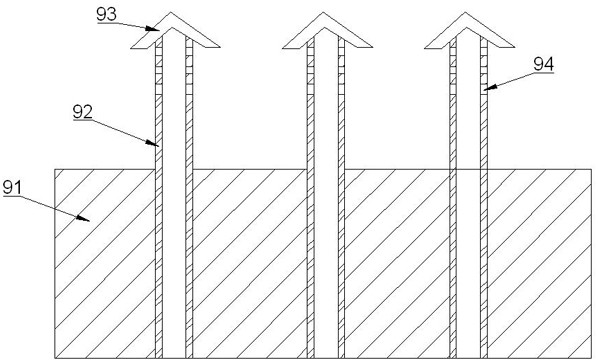

[0016] see figure 1 and figure 2 , a compound chlorination furnace for titanium tetrachloride production provided by the invention is composed of a boiling chlorination section and a molten salt chlorination section, the boiling chlorination section is the upper part of the composite chlorination furnace, and the molten salt chlorination section is located in the composite The lower part of the chlorination furnace is provided with a gas distributor 9 between the lower end of the boiling chlorination section and the upper end of the molten salt chlorination section. The gas distributor 9 is a cylindrical component 91 cast by refractory castable, and evenly distributed ventilation pipes 92 are pre-embedded in the cylindrical castable comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com