A spatio-temporal collaborative control weakening method for hard coal seam roof

A coal seam roof, collaborative control technology, applied in earth-moving drilling, surface mining, underground mining and other directions, can solve problems such as high premise cost, large drilling volume, weakening cracking effect, etc., to increase drilling utilization rate, Wide applicability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

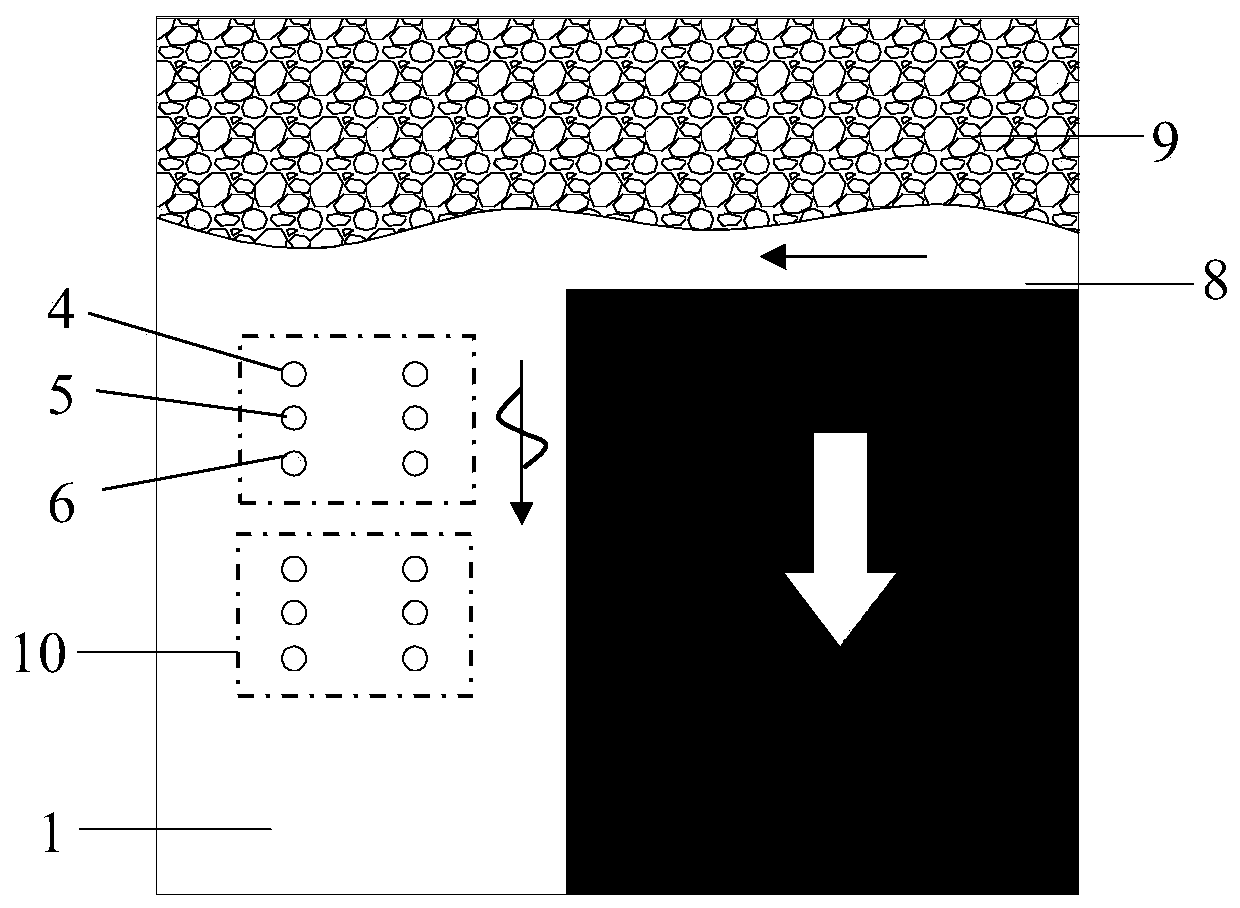

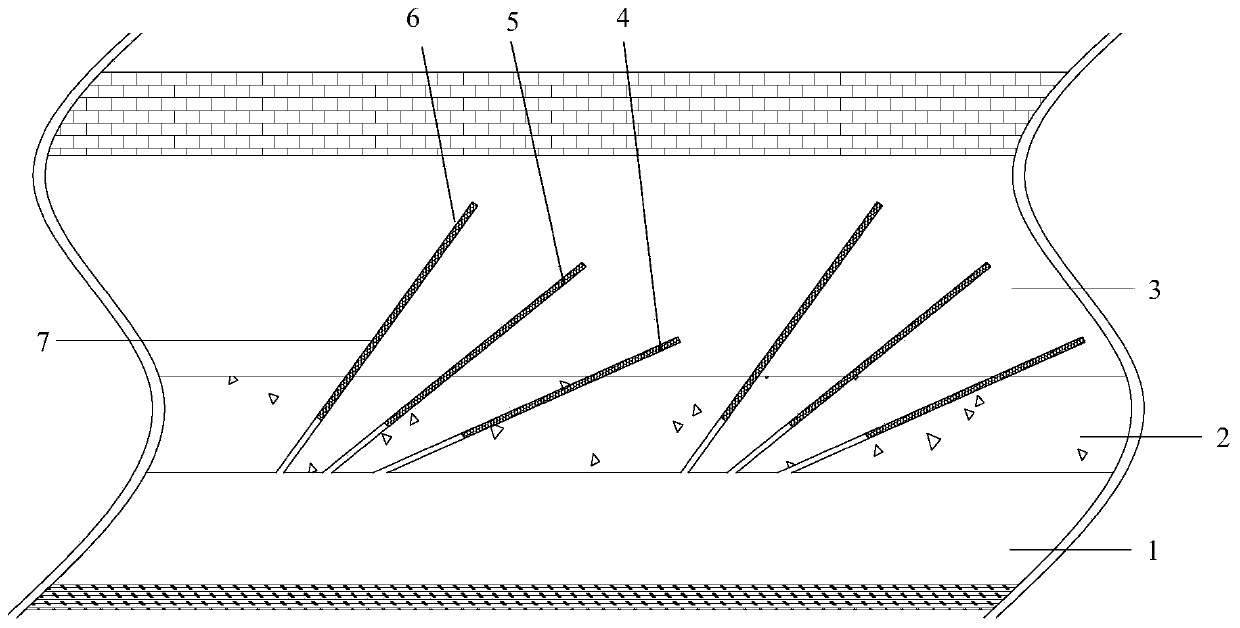

[0019] Such as Figures 1 to 4 As shown, a method for weakening the roof of a hard coal seam through space-time coordinated control of the present invention is applicable to the weakening and fracturing of the hard roof when there is no free surface in the goaf 9, and aims at pre-cracking and destroying the integrity of the rock formation to create more Effective free space, the method includes the following steps:

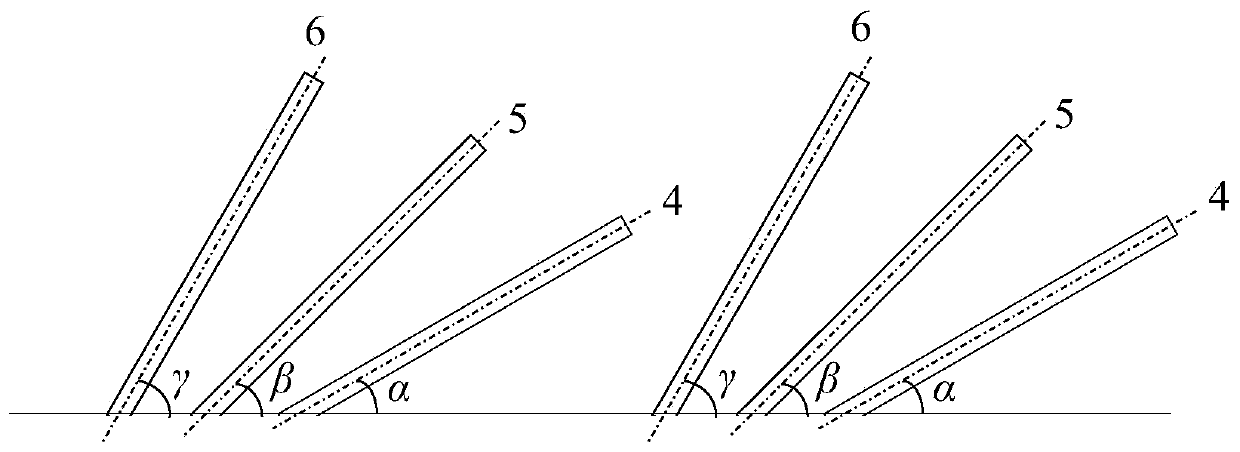

[0020] Advanced drilling: on the roof of the return airway 1, several advanced weakening fracturing drilling groups 10 are sequentially drilled along the advancing direction of the coal seam working face 8, and the advanced weakening fracturing drilling 10 passes through the direct roof 2 to reach the old roof 3, Each advanced weakening fracturing drilling group 10 includes a first row of fracturing drilling holes 4, a second row of fracturing drilling ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com