Secondary hole sealing method for treating broken area after extraction of crossing hole

A technology of broken area and secondary hole sealing, which is applied in earth-moving drilling, sealing/packing, wellbore/well components, etc. It can solve the problems of air leakage, shorten the validity period of gas drainage, and reduce the utilization rate of drilling holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

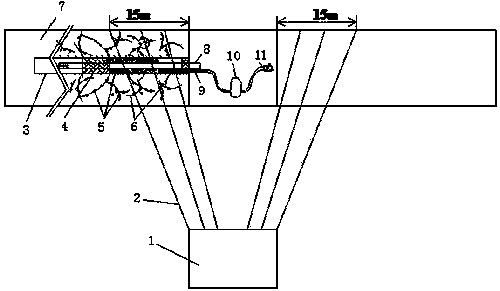

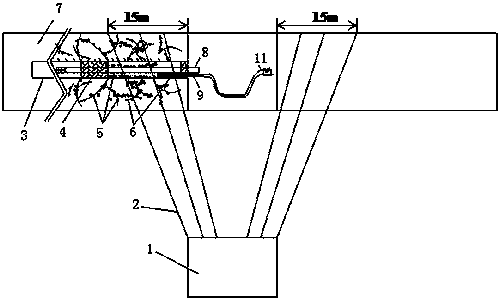

[0018] Embodiment 1: this secondary sealing method comprises the steps:

[0019] a. Take a PE sealing pipe with a length of 20-25m, and seal the borehole along the bedding to form the sealing section of the first borehole;

[0020] b. Send the blowing tube into the drilled hole along the layer, and seal the hole with cotton yarn stained with polyurethane;

[0021] c. Connect the downhole compressed air system with the blowing pipe through the solid particle conveyor;

[0022] d. Under the action of the wind pressure of the downhole compressed air system, the solid particles in the solid particle conveyor are blown into the borehole through the blowing pipe, and when solid particles gushes out through the coal wall near the drill hole, stop blowing in the solid phase particles;

[0023] e. Connect the downhole compressed air system directly with the blowing pipe, and press air into the borehole.

[0024] The depth of the first drilling is not less than 15m, the length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com