High-strength hole sealing agent for coal mine gas extraction drilling

A technology for drilling and mining gas in coal mines, which is applied in gas discharge, mining equipment, earthwork drilling and mining, etc. It can solve the problem of slow consolidation of ordinary Portland cement mortar, endangering human health and social safety, and failure to seal holes to reduce the risk of spontaneous combustion, prolong the period of gas drainage, and improve the quality of sealing holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

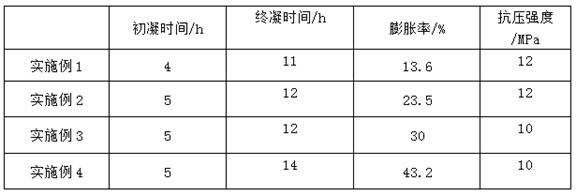

Examples

Embodiment 1

[0019] A high-strength sealing agent for coal mine gas drainage drilling, prepared from the following raw materials in parts by mass: 2 parts of graphene, 7 parts of short basalt fibers, 65 parts of Portland cement, 20 parts of anhydrous gypsum, 10 parts of fly ash, 1 part of bauxite, 2 parts of calcium sulfoaluminate, 0.5 parts of magnesium oxide, 0.5 parts of calcium oxide, 2 parts of powder polycarboxylate superplasticizer, 1 part of calcium acetate, 0.5 parts of calcium phosphate, 0.2 part of sodium aluminate, 0.1 part of sodium carbonate, and 0.1 part of quicklime; the length of short basalt fibers is 0.5-2mm.

[0020] The above raw materials are mixed into a uniform powder, and the prepared powder material is mixed with a certain amount of water to make a sealing agent, and the water-cement mass ratio is 0.5:1.

Embodiment 2

[0022] A high-strength sealing agent for coal mine gas drainage drilling, prepared from the following raw materials in parts by mass: 4 parts of graphene, 7 parts of short basalt fibers, 69 parts of Portland cement, 25 parts of anhydrous gypsum, 15 parts of fly ash, 1 part of bauxite, 1 part of calcium sulfoaluminate, 0.5 parts of magnesium oxide, 0.5 parts of calcium oxide, 1 part of powdered polycarboxylate superplasticizer, 1 part of calcium acetate, 0.5 parts of calcium phosphate, 0.2 parts of sodium aluminate, 0.2 parts of sodium carbonate, and 0.1 part of quicklime; the length of short basalt fibers is 0.5-2mm.

[0023] The above raw materials are mixed into a uniform powder, and the prepared powder material is mixed with a certain amount of water to make a sealing agent, and the water-cement mass ratio is 0.5:1.

Embodiment 3

[0025] A high-strength sealing agent for coal mine gas drainage drilling, prepared from the following raw materials in parts by mass: 5 parts of graphene, 5 parts of short basalt fibers, 50 parts of Portland cement, 25 parts of anhydrous gypsum, 15 parts of fly ash, 2 parts of bauxite, 1 part of calcium sulfoaluminate, 1 part of magnesium oxide, 0.5 parts of calcium oxide, 1 part of powder polycarboxylate superplasticizer, 1.5 parts of calcium acetate, 1 part of calcium phosphate, 0.2 parts of sodium aluminate, 0.1 parts of sodium carbonate, and 0.2 parts of quicklime; the length of short basalt fibers is 0.5-2mm.

[0026] The above raw materials are mixed into a uniform powder, and the prepared powder material is mixed with a certain amount of water to make a sealing agent, and the water-cement mass ratio is 0.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com