Four-period-five-purpose hole-drilling high-efficiency gas extracting process

A technology for gas extraction and process method, which is applied in the directions of gas discharge, earth-moving drilling, mining equipment, etc., can solve the waste of drilling through layer drainage, difficult construction of through-layer drilling, restricting coal seam roadway excavation and working face recovery speed and other issues, to achieve the effect of improving the utilization rate of drilling holes, reducing the amount of engineering, and eliminating gas disasters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

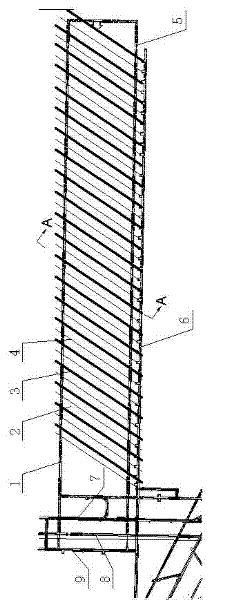

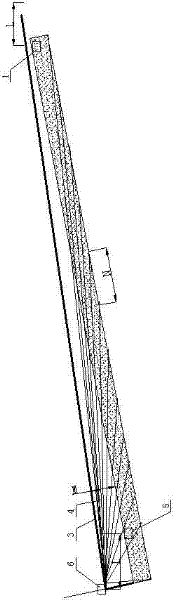

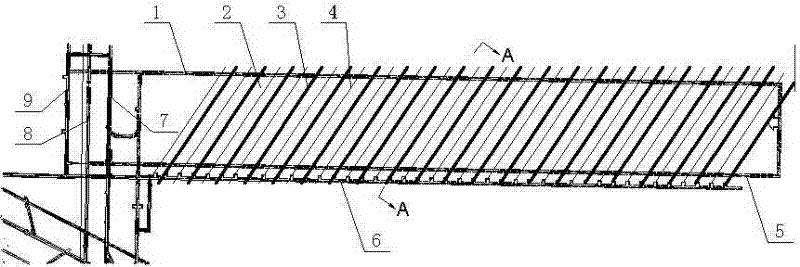

[0021] Depend on figure 1 and figure 2 The shown "four-stage five-use" drilling method for high-efficiency gas drainage includes the following steps:

[0022] (1) Select coal seam working face 2, which has outstanding danger and is difficult to directly excavate coal seam roadway, as the construction object;

[0023] Through the test of coal seam gas pressure and gas content, combined with the relevant national and local coal supervision regulations on roadway excavation in outburst coal seams, the working face 2 with serious outburst risks and difficult drilling in coal seam construction was selected as the research object. Of course, coal seams that do not have the risk of outburst can also be controlled by the "four-stage five-purpose" drilling high-efficiency gas drainage process method, but seriously outburst coal seams (such as soft and hard-to-drill coal seams) can more reflect this. Superiority of workmanship.

[0024] (2) Drill holes for geological exploratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com