A new process for underground gas control in abandoned mines

A new technology, gas technology, applied in the direction of gas discharge, mining equipment, mining equipment, etc., can solve the problems of abandoned mine gas comprehensive treatment and utilization industrialization blank, achieve good environmental benefits and realize the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

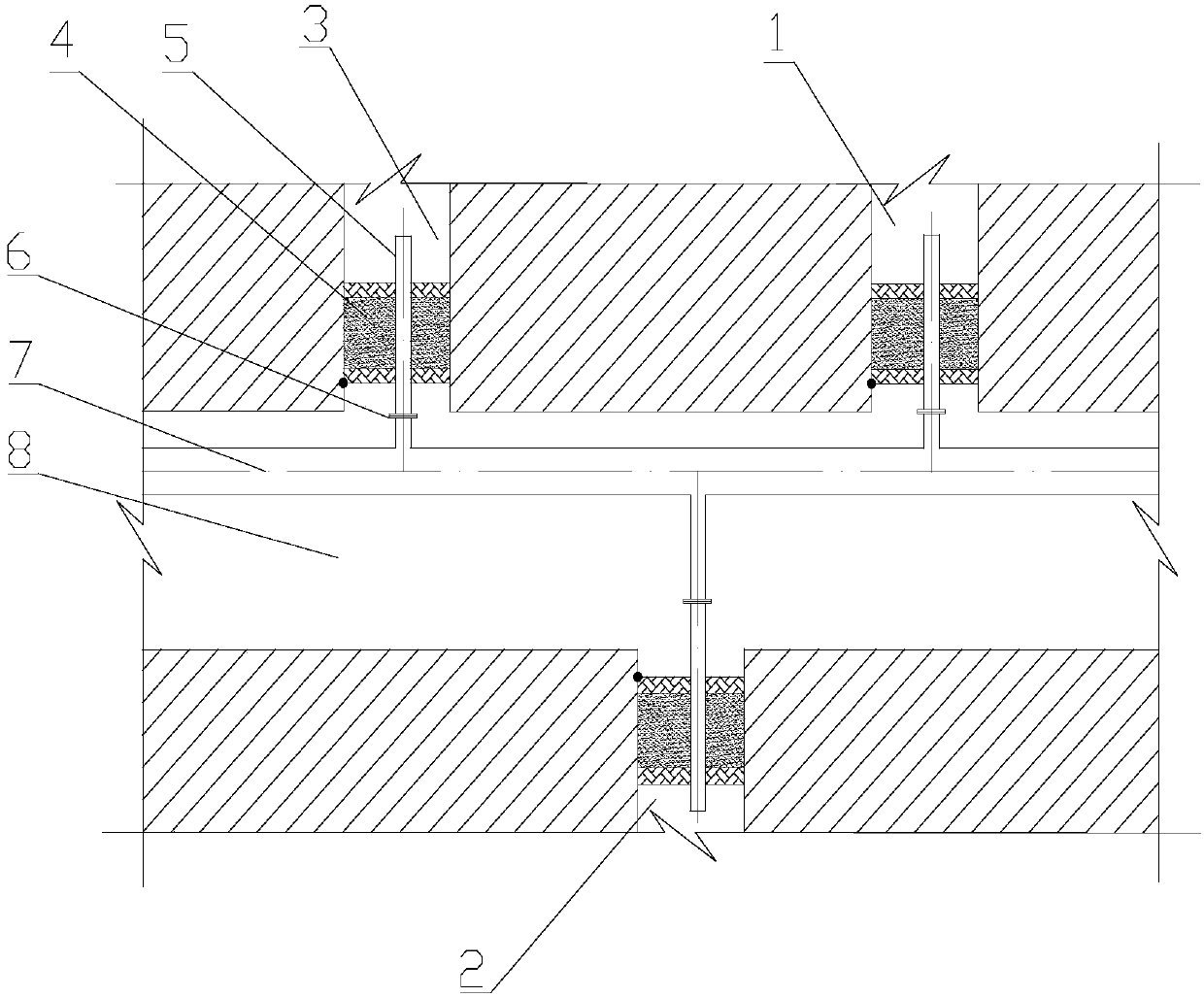

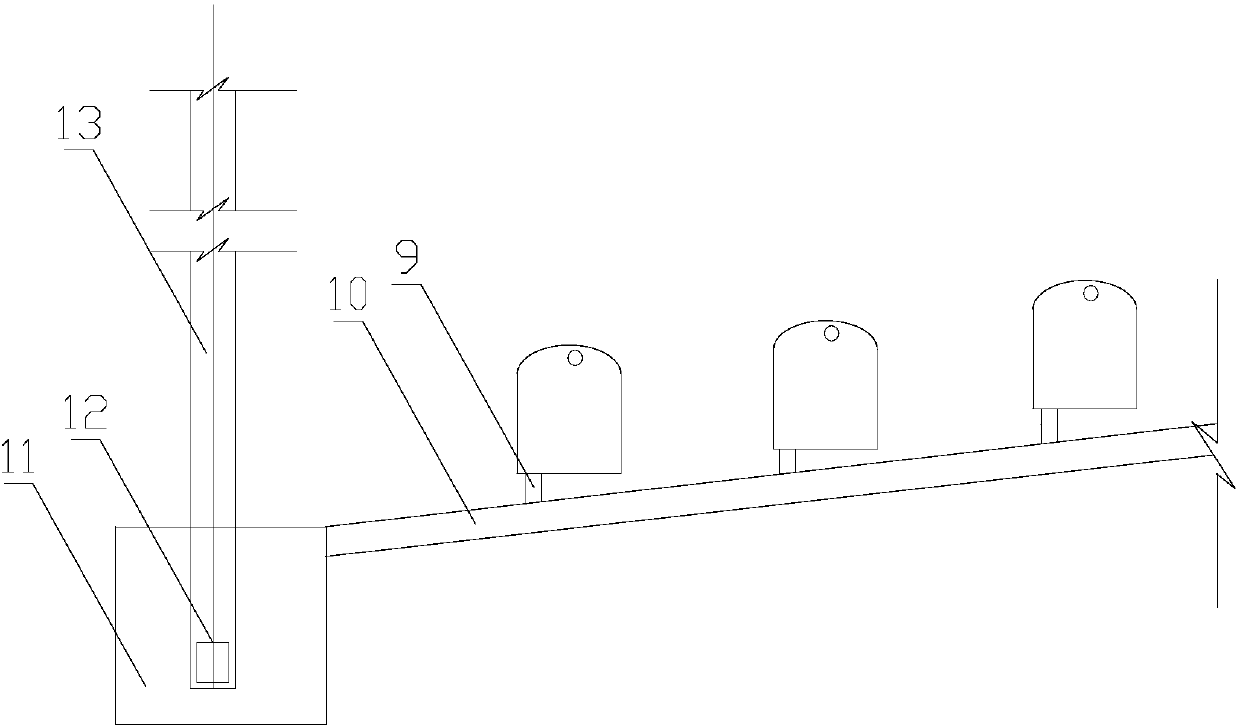

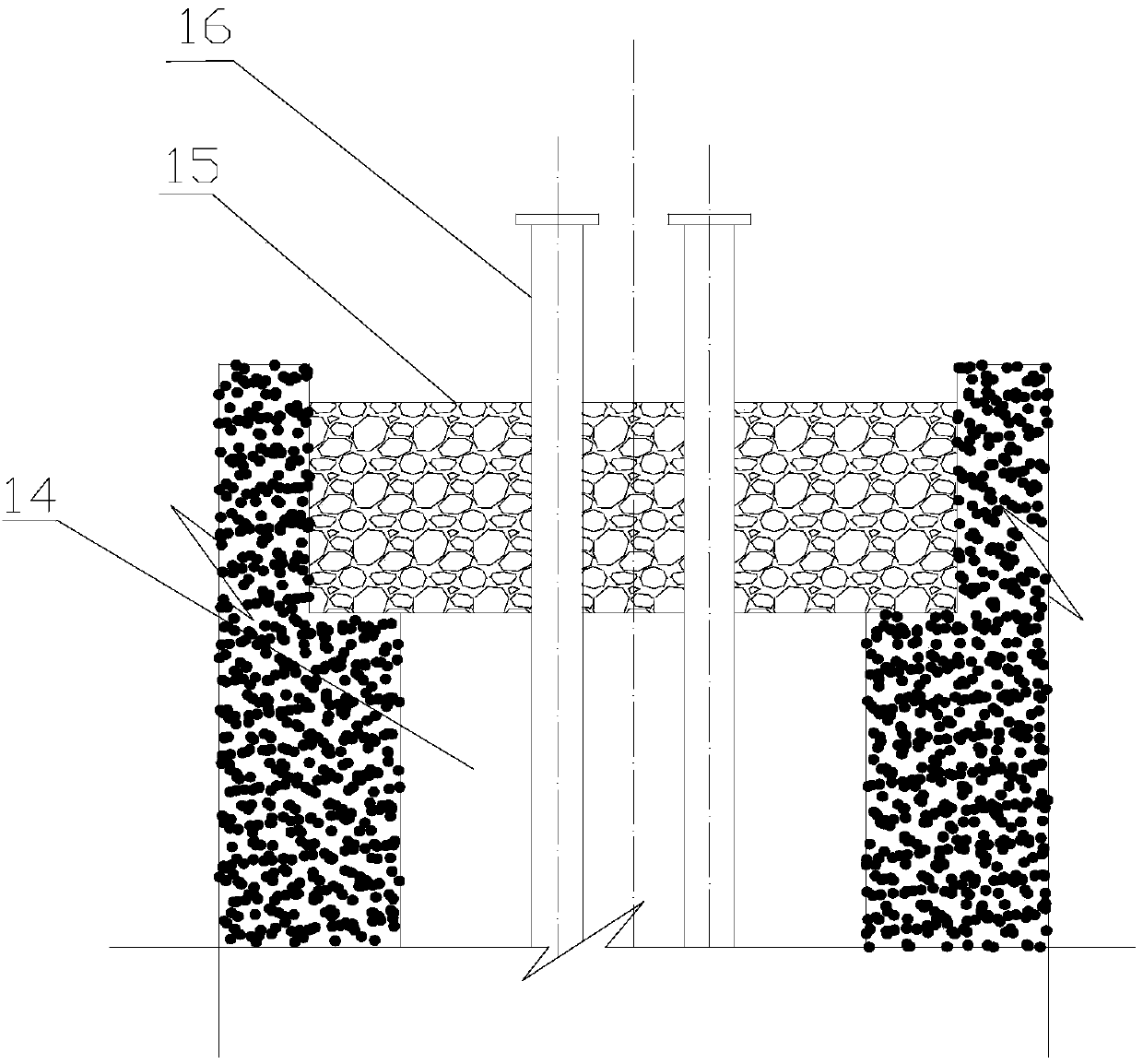

[0021] Such as figure 1 As shown in Fig. 1, a new technology for underground gas control in abandoned mines. Before the abandoned mines are about to be closed, in the underground mining area of the abandoned mines and the working area of the goaf, the openings of roadways 1, 2, and 3 are about 8 meters inward. Build the sealing wall 4 respectively. The specific method is to build a sealing wall with material stones and cement mortar at a distance of 8 meters inside the sub-tunnel, with a thickness of about 0.8-1 meters, block the lane, fill and compact it with loess in the middle, with a thickness of 5 meters, and then place it on the outside. Then build a sealing wall with stone and cement mortar, with a thickness of about 0.8-1 meter. During the entire process of building the sealing wall, a DN100-DN200 thick slab should be embedded at a distance of 0.2-0.3 meters from the top of the tunnel on the sealing wall. Pre-buried pipeline 5, through this pre-buried pipeline 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com