Fast tunneling method for injecting high-temperature nitrogen through drilled holes in strata

A technology of layer-penetrating drilling and nitrogen gas, which is applied in the direction of earthwork drilling, gas discharge, mining fluid, etc., can solve the problems that affect the safety and efficiency of coal mines, slow roadway excavation speed, unbalanced coal mine excavation, etc., and achieve roadway excavation speed and Safety, fast roadway excavation speed, and the effect of accelerating the excavation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

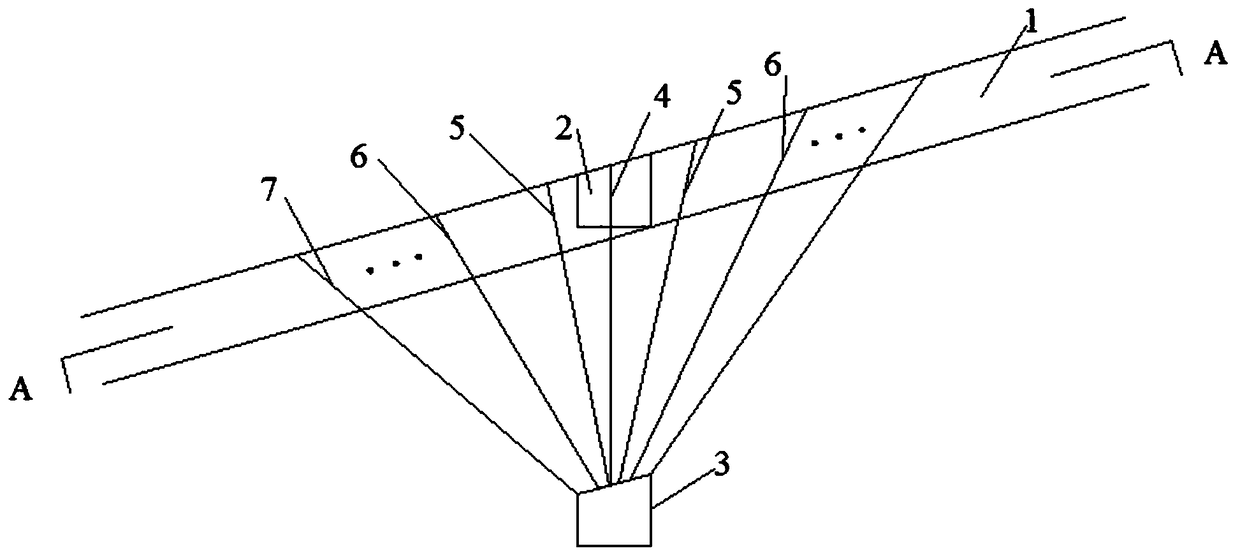

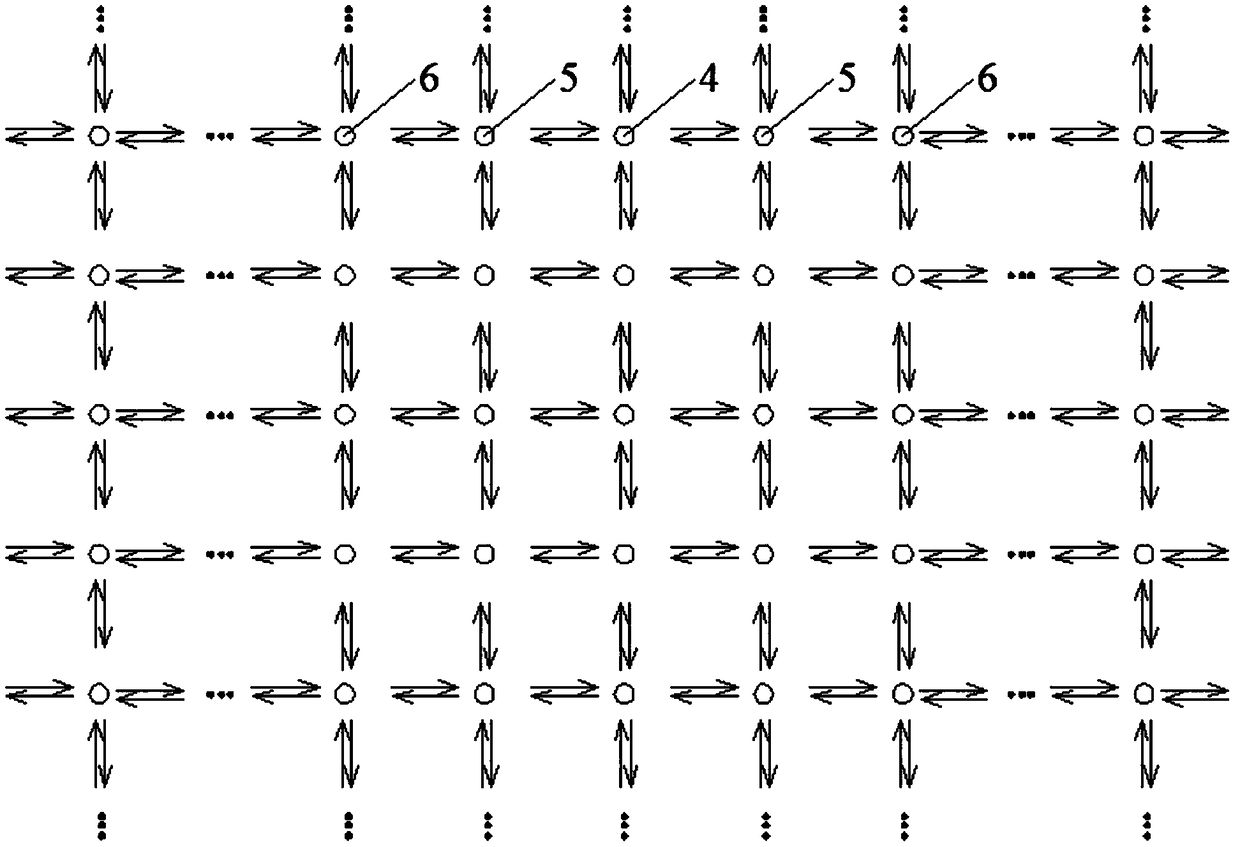

[0020] Such as figure 1 and figure 2 Shown, concrete steps of the present invention are:

[0021] A. Construct a group of linearly distributed bed-through drilling holes in the direction of the coal seam at intervals of 3 to 4m in the low-level drainage roadway to ensure that each group of bed-through drilling holes penetrates the coal seam and enters the coal seam roof for no less than 0.5m. The bed-through drilling is within the control range of roadway excavation; the control range of said roadway excavation is specifically: at least 20m outside the contour line of the upper side of the roadway in inclined and sharply inclined coal seam 1, at least 10m outside the lower side of the roadway, and at least 10m outside the contour line on both sides of the roadway for others. 15m each; the number of each group of piercing boreholes is an odd number, and each group of piercing boreholes in the middle is a first-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com