Coal face fissure zone gas extraction method

A coal mining face and gas drainage technology, applied in the direction of gas discharge, mining fluid, mining equipment, etc., can solve the problems of low effective utilization rate of drilling holes, high cost of excavation, long construction period, etc., and achieve significant economic benefits and Social benefit, good governance effect and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

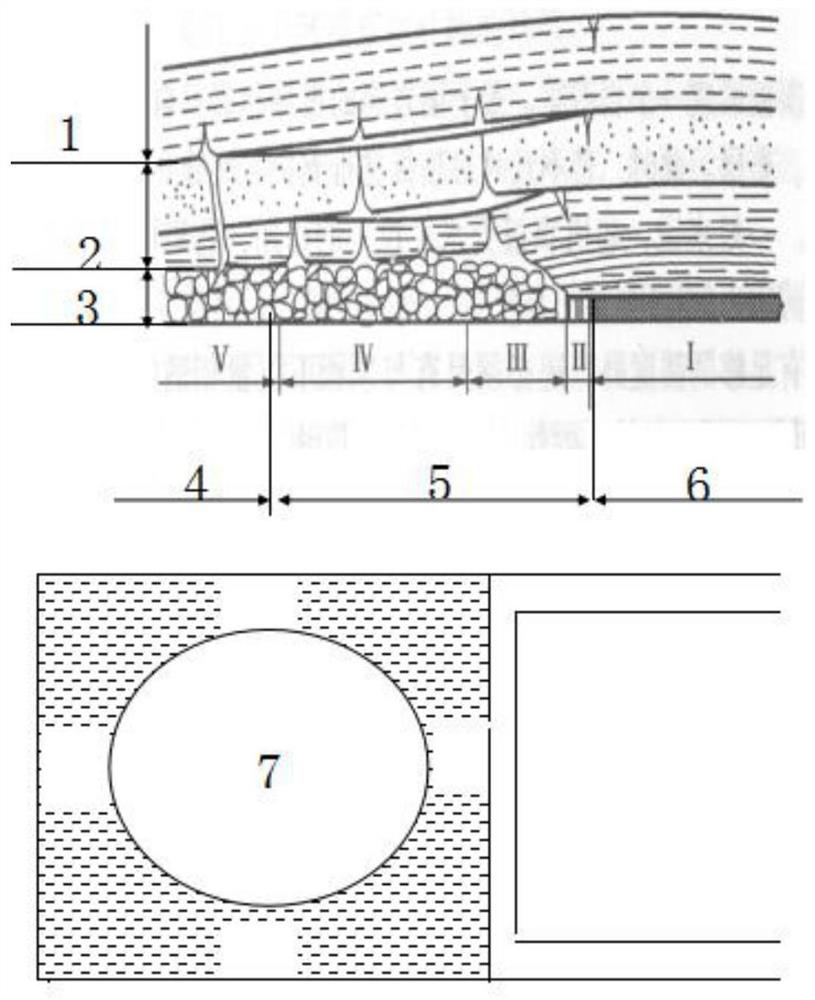

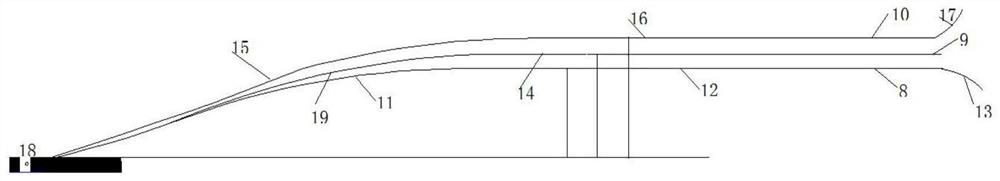

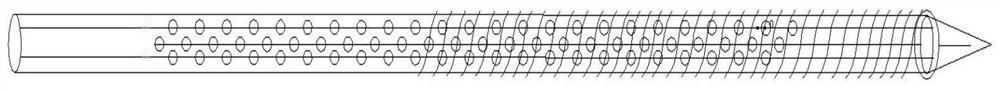

[0034] Such as figure 1 As shown, the roof strata experienced a cyclical process of unloading subsidence, breaking, and collapsing with the advancement of the working face. During the deformation and collapse of the roof, the gas in the goaf and the overlying strata undergoes the process of desorption, diffusion, infiltration, and accumulation, and finally forms relatively concentrated gas, high gas concentration and easy gas in the overlying strata in the goaf. In the flow area, according to the degree of deformation and damage of the overlying strata in the goaf, the stress state and the scale of the cracks, the overlying strata are divided into "three zones" vertically, namely the caving zone 1, the crack zone 2 and the bending deformation zone 3 . Along the advancing direction of the working face (referred to as the longitudinal direction), from the coal body or the cutting hole of the working face to the longitudinal middle of the goaf are successively the coal wall supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com