A closed anti-sedimentation coating machine

An anti-sedimentation and closed technology, which is applied in the direction of coatings and devices for coating liquid on the surface, can solve the problems of anti-sedimentation and use safety, explosion, fire or explosion of feeding equipment, etc., and achieve enhanced anti-sedimentation effect, enhanced stirring effect, and the effect of preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

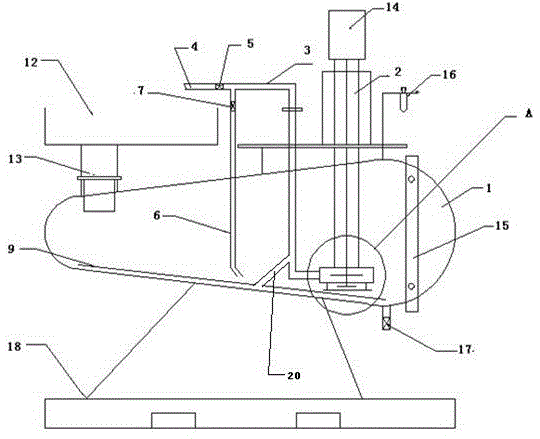

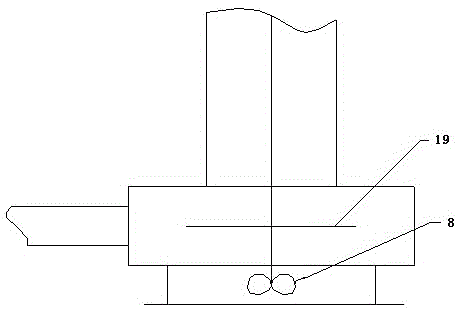

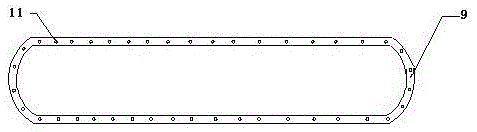

[0036] Such as figure 1 As shown, this embodiment provides a paint machine, including a sealed tank 1 for containing liquid paint, the sealed tank 1 is arranged on the bracket 18; a liquid pump 2 is inserted into the sealed tank 1 Below the liquid level of the paint inside, it is used to pump the paint; the discharge pipe 3 is connected with the liquid pump, and is used to receive the paint pumped from the liquid pump 2 and send the paint Draw outside described sealed tank body 1; And spray gun 4, be installed in the outlet of described discharge pipe 3, communicate with described discharge pipe 3 by switching valve 5 or disconnect; Return pipe 6, one end is inserted into the In the sealed tank 1, the other end is connected or disconnected with the discharge pipe 3 through the one-way valve 7, and it is also arranged below the entire liquid level of the sealed tank 1 and connected with the outlet pipe 20 through a connecting pipe 20. Stirring part 9 that material pipe 3 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com