A drilling and anchoring structure for monitoring cracks in the surrounding rock of the floor and its construction method

A construction method and drilling anchor technology, which are used in earth-moving drilling, wellbore/well components, construction, etc., can solve problems such as increased monitoring costs, hidden safety hazards in normal construction, and shallow bottom plate drilling holes, etc., and achieve savings. Instrument loss and materials, avoid collapse hole accidents, overcome the effect of softening shrinkage holes in water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

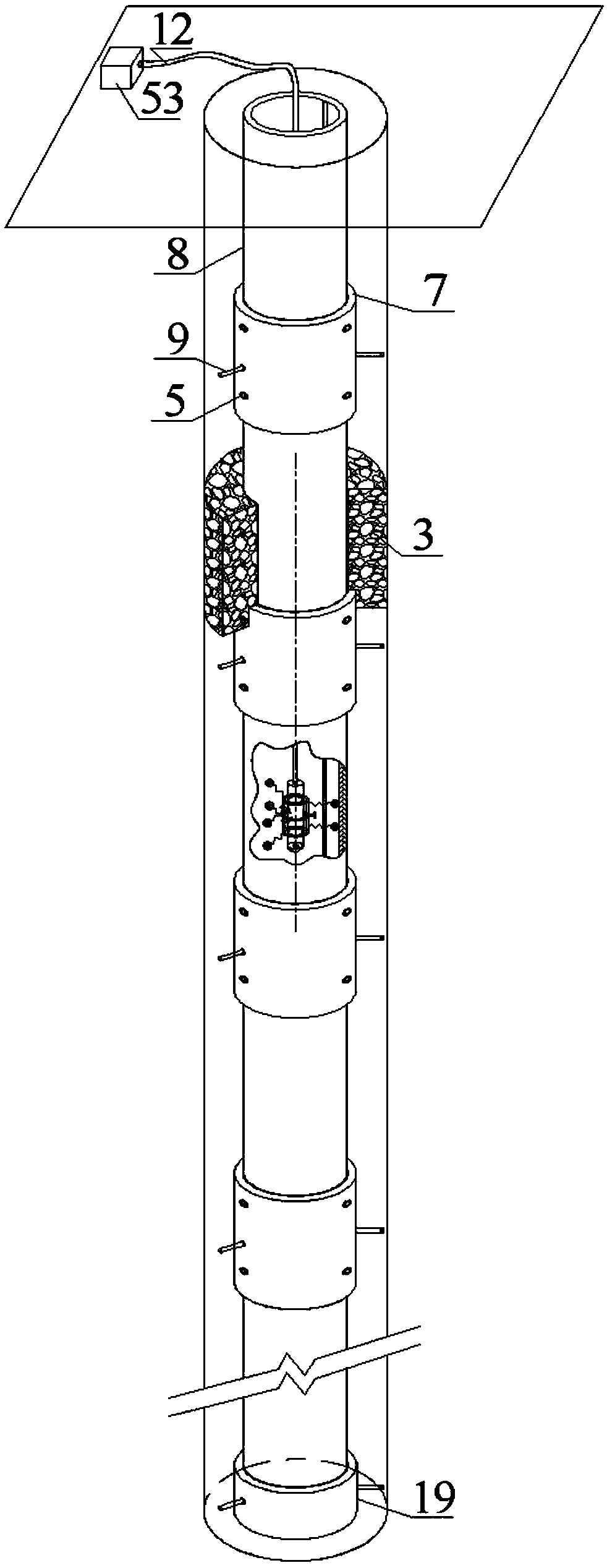

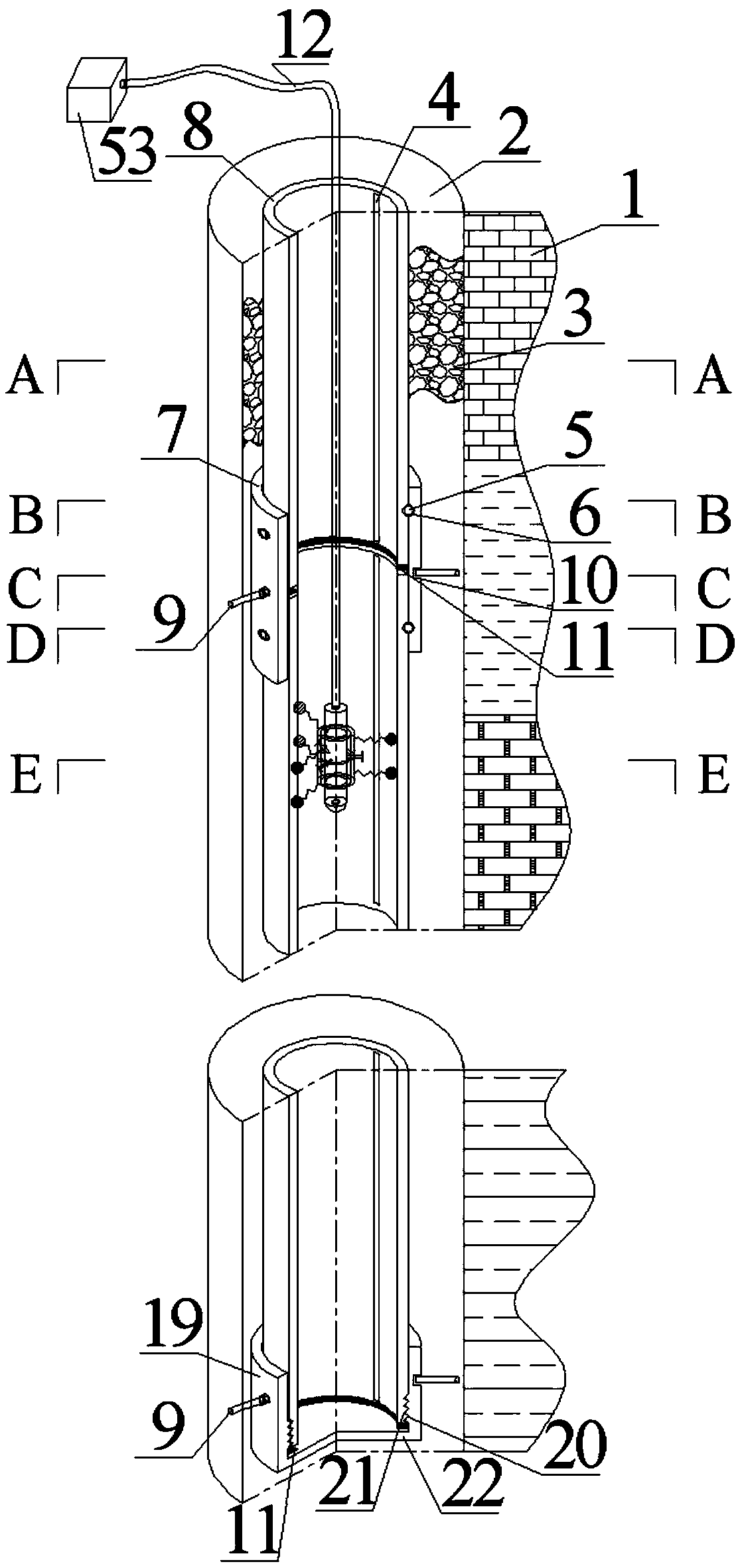

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

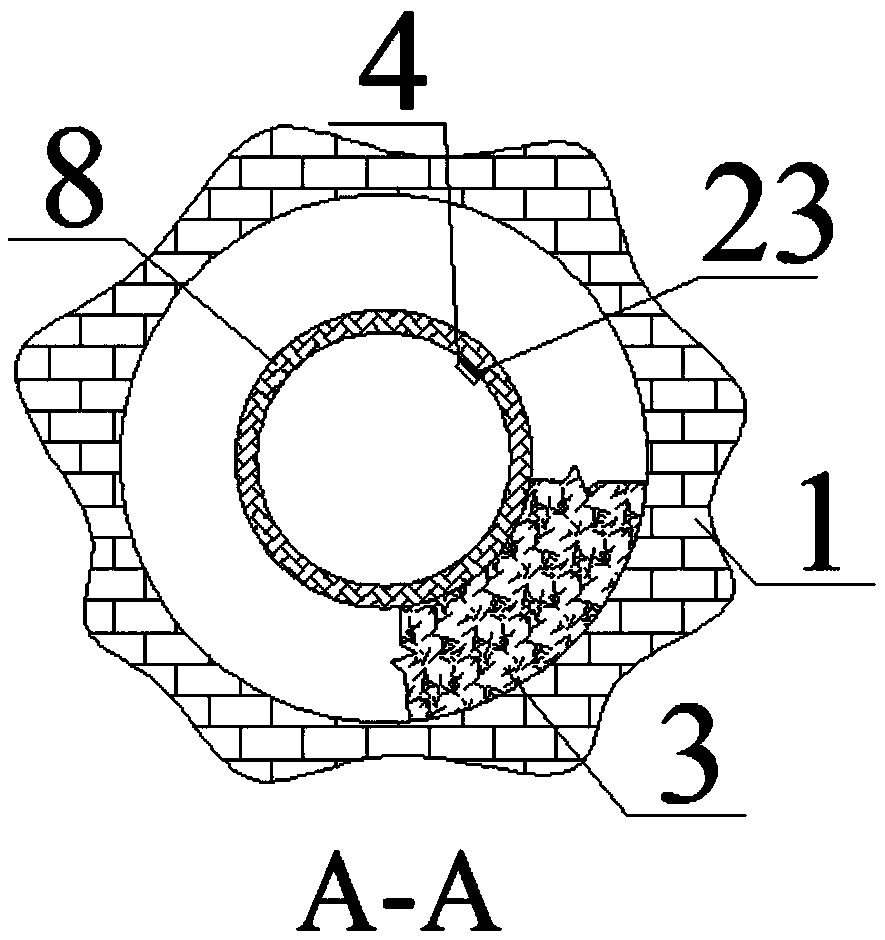

[0056] As shown in the figure, a drilling casing anchorage structure for monitoring cracks in the surrounding rock of the floor includes a floor borehole 2, and the periphery of the floor borehole 2 is the surrounding rock mass 1 of the wall of the borehole. There is a sealed observation tube, and a detection and positioning component is arranged in the sealed observation tube;

[0057] The sealed observation tube includes a plurality of interconnected transparent hollow tubes 8, and the adjacent transparent hollow tubes 8 are connected together by a docking sealing assembly, and the docking sealing assembly includes a docking sleeve 7 and is arranged on both ends of the docking sleeve 7. The two ends of the docking sleeve 7 are respectively set on the ends of the adjacent transparent hollow tube 8, and the two "U"-shaped clips 5 are respectively perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com