A combined multi-electrode high-voltage pulse discharge fragmentation hard rock device and fragmentation method

A high-voltage pulse discharge and multi-electrode technology, which is applied in the field of rock crushing, can solve the problems of limited crushing area and low crushing efficiency, and achieve the effect of reducing the strength of rock mass, ensuring the fragmentation effect, and releasing less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

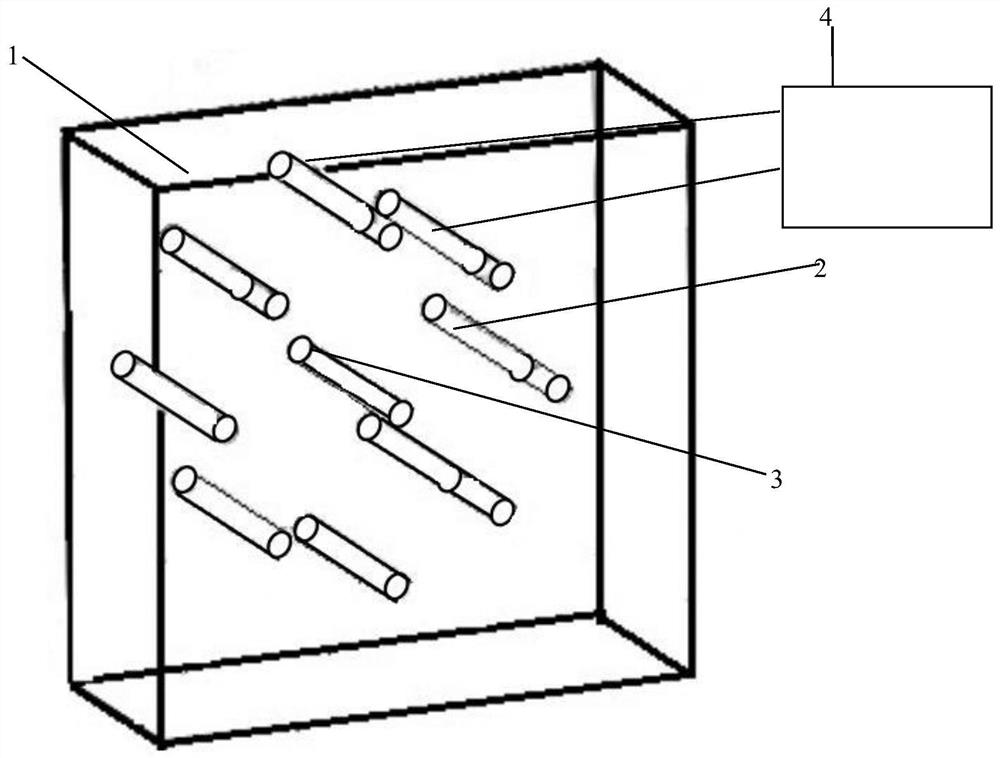

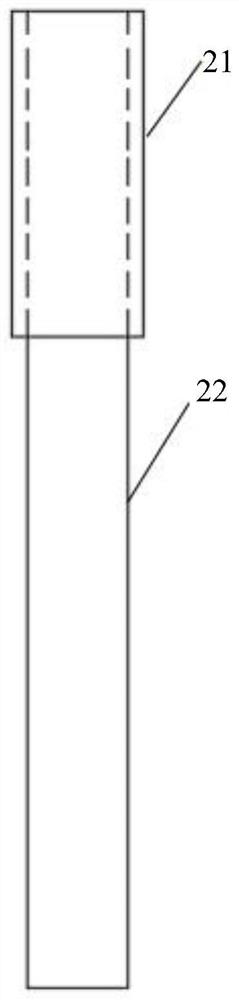

[0039] See attached figure 1 As shown, Embodiment 1 of the present invention discloses a combined multi-electrode high-voltage pulse discharge fragmentation hard rock device, which is applied to the rock mass 1 to be crushed, including: negative electrode 2, positive electrode 3 and pulse power meter 4;

[0040] The rock mass 1 to be crushed is pre-set with a plurality of operation holes matched with the negative electrode 2 and the positive electrode 3 , and both the negative electrode 2 and the positive electrode 3 are electrically connected with the pulse power meter 4 .

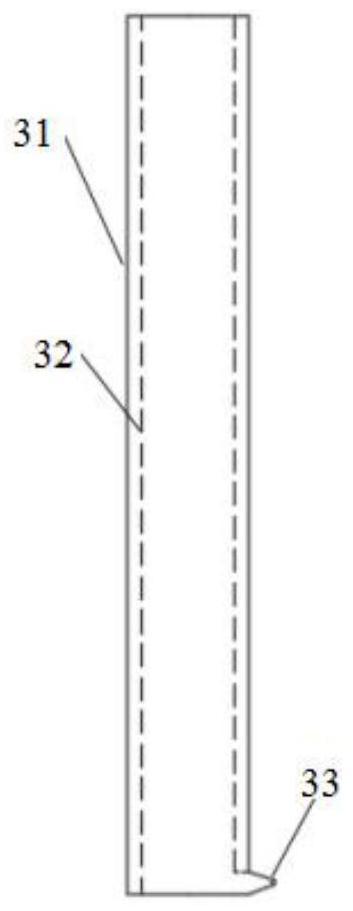

[0041] See attached figure 2 As shown, in a specific embodiment, the positive electrode 3 includes: a positive electrode carrying rod 31, an insulating layer 32 and a tip portion 33, the positive electrode carrying rod 31 is sleeved inside the insulating layer 32, and the tip portion 33 is connected to the positive electrode carrying rod 31. One end is fixedly connected, and the tip can be arranged at d...

Embodiment 2

[0050] A rock fracturing method using any one of the combined multi-electrode high-voltage pulse discharge fracturing hard rock devices in Embodiment 1, comprising:

[0051] S1: Use a drilling rig to process multiple operating holes on the rock mass 1 to be broken. One of the operating holes is the central hole, and the remaining operating holes are peripheral holes. The peripheral holes surround the central hole and are at the same distance from the central hole. The size of the hole is compatible with the negative electrode 2 and the positive electrode 3;

[0052] S2: placing the negative electrode 2 in the central hole, and placing a plurality of positive electrodes 3 in the remaining peripheral holes;

[0053] S3: Connect the negative electrode 2 and the positive electrode 3 to the pulse power meter 4 to carry out discharge rock breaking operation.

[0054] In a specific embodiment, the peripheral hole surrounds the central hole, and the distance between the peripheral ho...

Embodiment 3

[0057] See attached Figure 4-9 As shown, red sandstone is selected as the rock mass to be broken. Firstly, a drilling machine is used to drill an operation hole in the rock body to be crushed. The depth of the operation hole is 12cm, and there are 6 operation holes in total. The negative electrode is placed in the working hole, and the positive electrode is placed in the remaining working holes. The distance between the positive and negative holes is 1.5cm, and the pulse voltage is set to 40kv; the negative electrode is insulated for a certain length near the hole, and the other parts are bare metal. Conductor, the positive electrode is placed in the peripheral hole, and the discharge tip points to the center of the circle where the negative electrode is located; in Example 3, through the above-mentioned electrode arrangement, a multi-pair electrode combination of one negative electrode and n positive electrodes is formed, ready for discharge rock breaking operations at any ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com