Wall mounting structure for assembly type arrow shaped expanding plug leveling part

An installation structure and prefabricated technology, applied in building construction, covering/lining, construction, etc., can solve problems such as poor stability, damaged walls, and inability to install at corners, so as to improve stability, improve work efficiency, and reduce construction. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

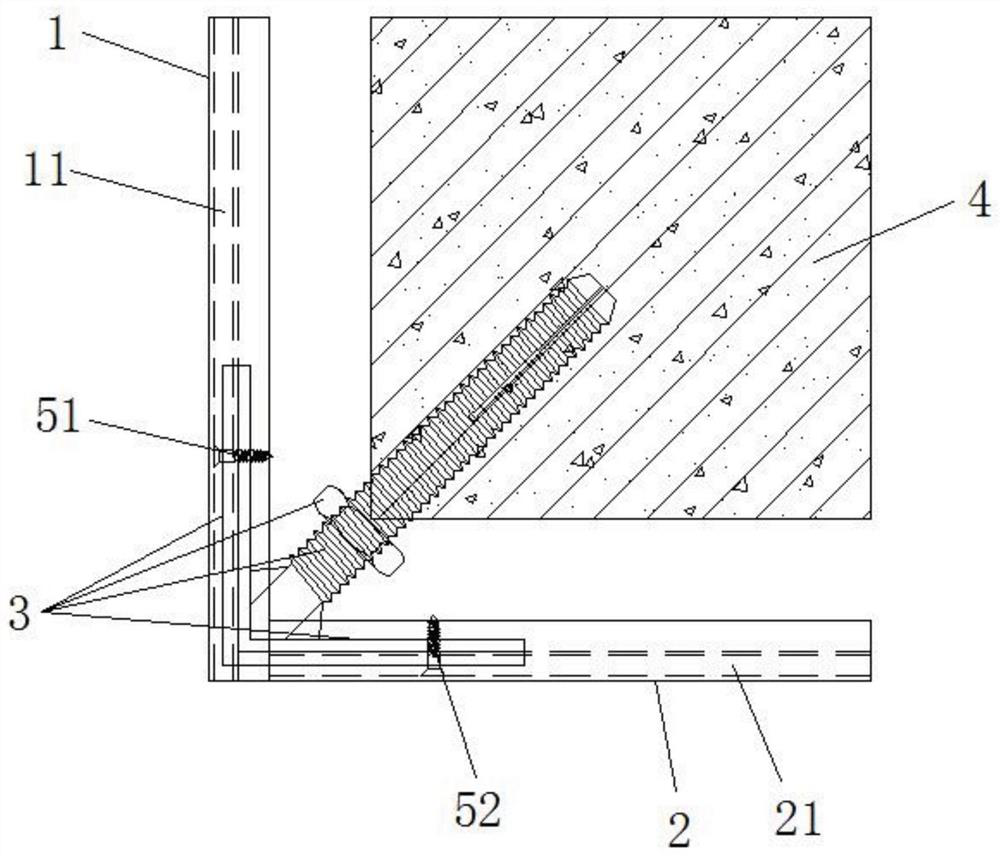

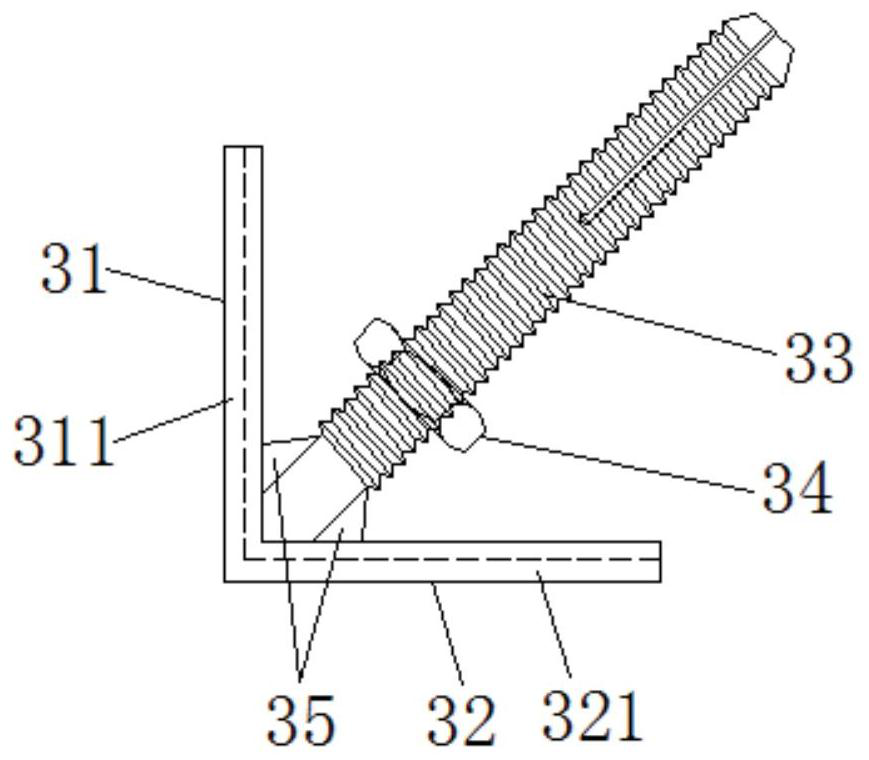

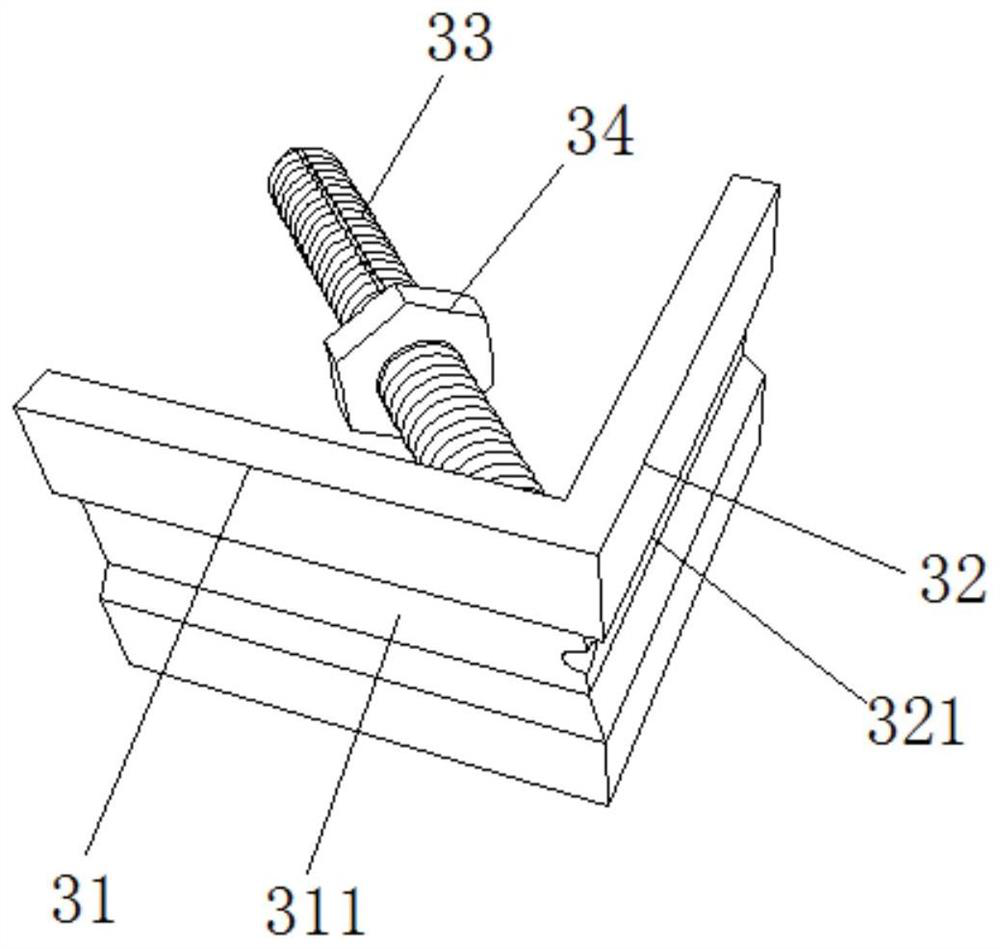

[0031] see Figure 1 to Figure 3 , the figure shows a wall installation structure of an assembled arrow-shaped expansion plug leveling member provided by Embodiment 1 of the present invention, which mainly includes: a first keel 1, which is arranged on one side of the male corner of the base wall The outer wall; the second keel 2, which is arranged on the other side outer wall at the male corner of the base wall; the arrow-shaped expansion plug leveling part 3, which includes a first connecting plate 31, a second connecting plate 32, an expanding plug screw 33 and The positioning nut 34, the first connecting plate 31 and the second connecting plate 32 are symmetrically arranged on the end of the expansion plug screw 33, the positioning nut 34 is sleeved on the expansion plug screw 33, and the expansion plug screw 33 is fixed on the male of the base wall 4. Angular position; the first connecting plate 31 is connected with the first keel 1 , and the second connecting plate 32 is...

Embodiment 2

[0040] see Figure 1 to Figure 3 , the figure shows a wall installation structure of an assembled arrow-shaped expansion plug leveling member provided by Embodiment 2 of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments The technical solution: the first connecting plate 31 and the second connecting plate 32 are perpendicular, and are symmetrical with respect to the expansion plug screw 33; the first connecting plate 31 and the second connecting plate 32 are of an integral structure. Through the arrangement of the above structure, the first connecting plate 31 and the second connecting plate 32 form an arrow-shaped structure, which not only improves their own rigidity, but also improves the connection strength between the first keel 1 and the second keel 2, and further improves the stability of the keel.

Embodiment 3

[0042] see Figure 1 to Figure 3 , the figure shows the wall installation structure of an assembled arrow-shaped expansion plug leveling piece provided by the third embodiment of the present invention. This embodiment further makes the following improvements on the basis of the above-mentioned embodiments The technical solution: the first connecting plate 31 is provided with a first connecting groove 311; the second connecting plate 32 is provided with a second connecting groove 321; the first keel 1 is provided with a first positioning groove 11, the first connecting groove 311 It corresponds to the position of the first positioning groove 11 ; the second keel 2 is provided with a second positioning groove 21 , and the second connecting groove 321 corresponds to the position of the second positioning groove 21 . Through the setting of the above structure, through the design of the connecting groove and the positioning groove, the keel and the connecting plate can be pre-posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com