Halloysite-based positive electrode material of lithium-sulfur battery and preparation method for positive electrode material

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, lithium storage batteries, nanotechnology for materials and surface science, etc. The effect of increasing the filling rate and increasing the inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Acid etching of halloysite

[0031] Grind the natural halloysite through a 300-mesh sieve, then weigh 1g of the halloysite powder that has been crushed and sieved, add it to 100ml of 2mol / L sulfuric acid, stir at 70°C for 6h, then centrifuge, wash, and dry in vacuum Dry in an oven at 110°C for 5 hours to obtain halloysite after acid etching and drying.

[0032] 2) Preparation of halloysite / sulfur composites

[0033] Take 0.16g of acid-etched halloysite powder and add it to 2ml of deionized water, place it in a vacuum environment for degassing for 4 hours, then add 2.4ml of 10mol HCl to the halloysite suspension and let it stand for 20 minutes, then ultrasonically disperse for 15 minutes , and then the suspension was added dropwise to 300ml of 0.04mol / L Na containing 0.02wt% PVP 2 S 2 o 3 In the solution, magnetically stirred for 3 hours, filtered and washed, and dried in a vacuum oven at 60° C. for 12 hours to obtain a halloysite / S composite. Then, the halloysit...

Embodiment 2

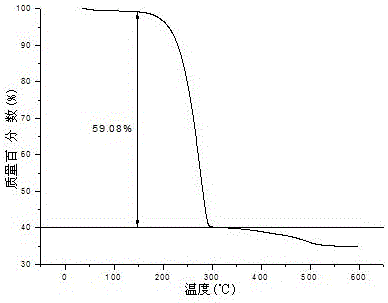

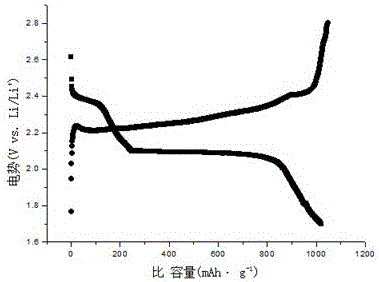

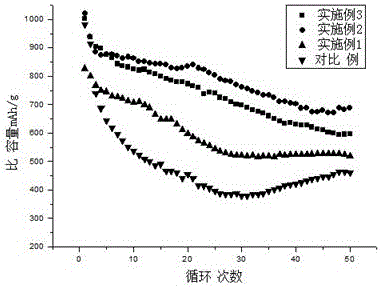

[0037] The acid etching temperature of halloysite in Example 1 was set to: stir at 80° C. for 6 h, and the others were the same as in Example 1. Calculated by thermogravimetric analysis, the actual content of sulfur in the composite material is 59.08%, as figure 1 shown. The test results are listed in Table 1, the first discharge capacity is: 1019.4mAh•g -1 ,The specific capacity after 50 cycles is: 687.48mAh•g -1 . Such as figure 2 ,3 shows that the charging and discharging platform is normal, and the cycle performance of the battery is improved.

Embodiment 3

[0039] The acid etching temperature of halloysite in Example 1 was set to: stir at 90° C. for 6 h, and the others were the same as in Example 1. The test results are listed in Table 1, the first discharge capacity is: 1002.2mAh•g -1 , specific capacity after 50 cycles: 598.2mAh•g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com