Comprehensive treatment method for organic acid-containing wastewater and iron mud

A comprehensive treatment and wastewater technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of low equipment requirements and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

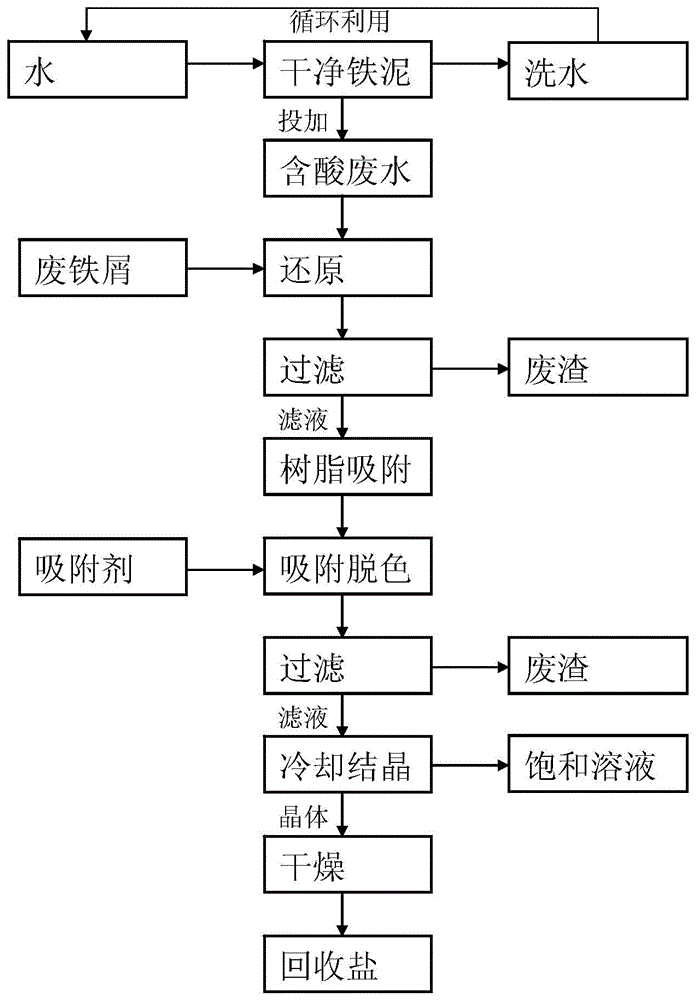

Image

Examples

Embodiment 1

[0033] The organic acid-containing wastewater produced during the production of T acid has a sulfuric acid content of 30% and COD=4400mg / L; the iron sludge produced is washed with water twice the weight of the iron sludge, and the water content of the iron sludge is measured to be 17%, and the iron sludge contains Fe 2 o 3 80% (based on the quality of dry iron mud).

[0034] 1. Acid soluble

[0035] Slowly add clean and moist iron mud to organic acid-containing wastewater. When the pH of the system is around 2, stop adding iron mud. The amount of iron mud added is 29% (based on the quality of organic acid-containing wastewater), and the reaction The liquid temperature was 55°C.

[0036] 2. Restore

[0037]Slowly add scrap iron scraps to the acid-dissolved wastewater, and at the same time add 50g / L activated carbon powder, stir the reaction and monitor the pH of the solution online, adjust the pH with organic acid-containing wastewater, and keep the pH at about 4. Add 45% o...

Embodiment 2

[0047] Same as the other operating steps in Example 1, only when the cooling crystallization temperature in step 4 was changed to 15°C, the purity of the recovered heptahydrate and ferrous sulfate was increased to 94.5%.

Embodiment 3

[0049] The organic acid-containing wastewater produced during the production of the reduced product (2-amino-4-acetamidoanisole), the content of sulfuric acid is 31%, and the COD=12500mg / L; the iron sludge produced is washed with water with an iron sludge quality of 60% , the water content of the iron mud was measured to be 19%, containing Fe 2 o 3 80%.

[0050] 1. Acid soluble

[0051] Slowly add clean and moist iron sludge to the organic acid-containing wastewater. When the pH of the system is around 1, the amount of iron sludge added is 25% (based on the quality of the organic acid-containing wastewater), and the temperature of the reaction solution is 50°C.

[0052] 2. Restore

[0053] Slowly add scrap iron scraps to the acid-dissolved wastewater, and at the same time add 3g / L activated carbon powder, stir the reaction and monitor the pH of the solution online, and adjust the pH with organic acid-containing wastewater. Keep the pH around 4. When adding 55% of scrap ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com