Preparation method of cathode isolation column of organic light emitting display

A technology of light-emitting display devices and isolation columns, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve problems affecting the life of light-emitting devices, diffusion, evaporation, and water vapor residues, etc., to improve OLED devices. Effects of longevity, pixel resolution improvement, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

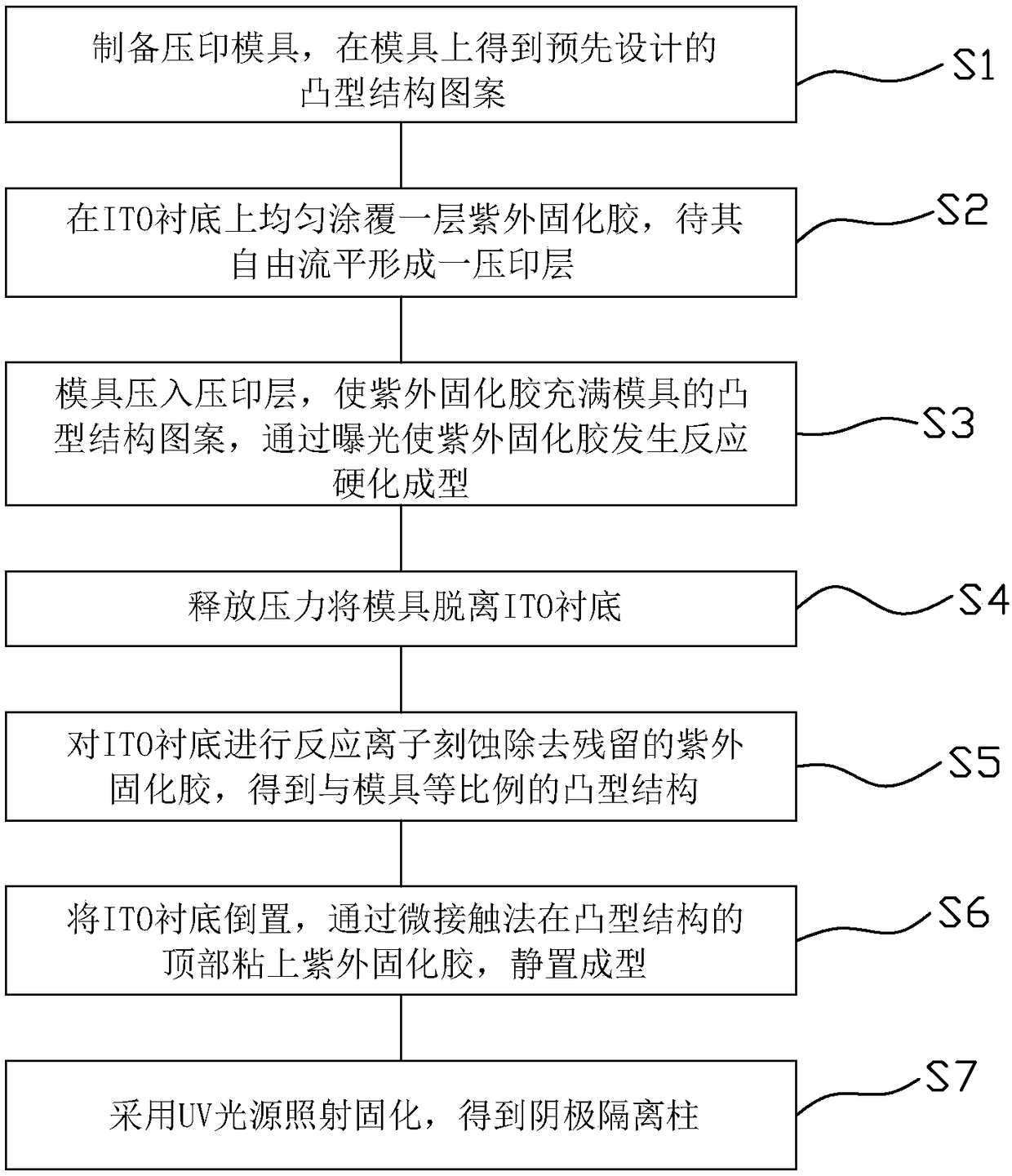

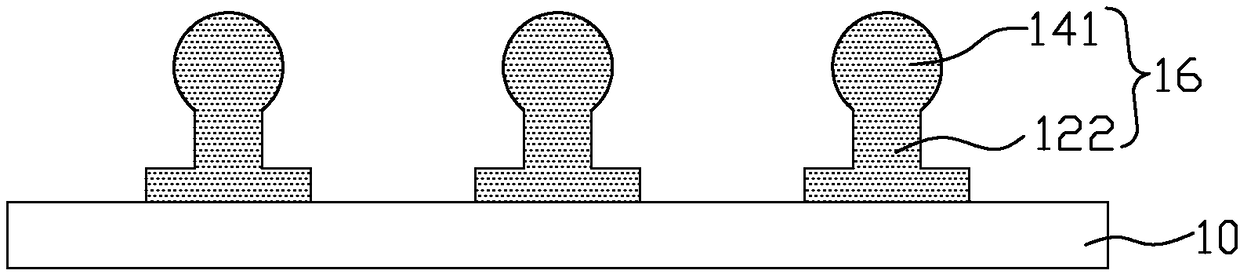

[0028] The invention provides a method for preparing a cathode isolation column of an organic light-emitting display device. see Figures 1 to 3f Shown, described preparation method comprises the steps:

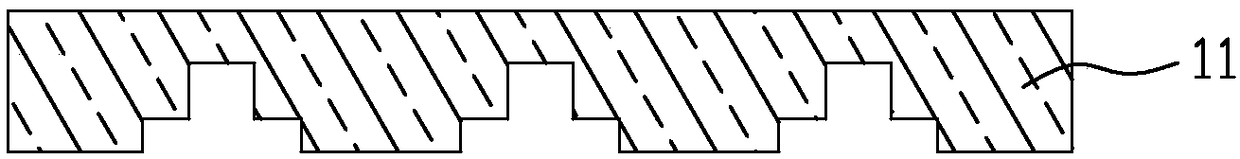

[0029] S1) if Figure 3a As shown, an imprinting mold 11 is prepared, and a pre-designed convex structure pattern is obtained on the mold 11 . Specifically, in this step, the imprinting mold 11 is prepared by electron beam lithography using transparent quartz that can allow ultraviolet rays to pass through. In other embodiments, the imprinting mold 11 can also be prepared by plasma etching, laser holographic interference and other technical methods.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com