Titanium-based composite anode and preparing method and application thereof

A composite anode and titanium-based technology, applied in the field of electrochemistry, can solve problems such as short service life, achieve long service life, inhibit passivation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

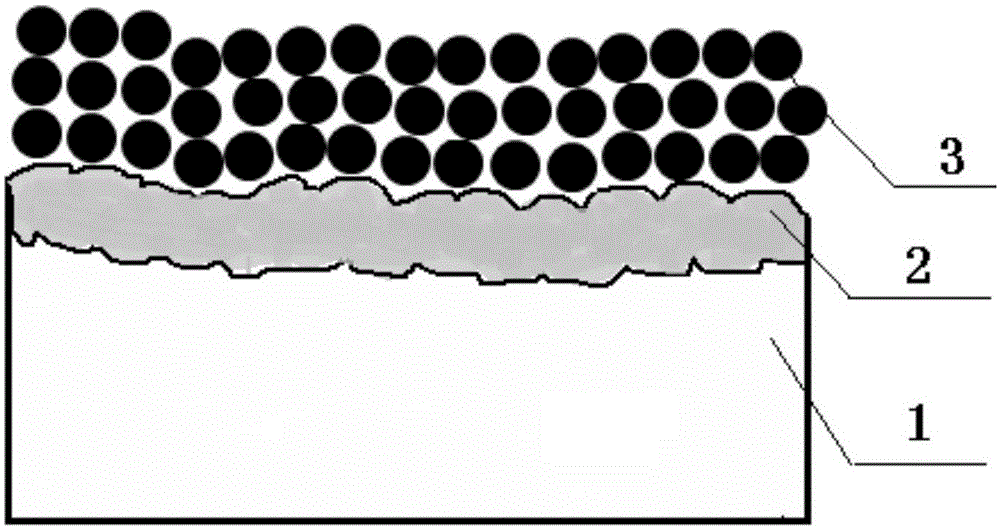

[0039] A titanium-based composite anode of the present invention, such as figure 1 As shown, it includes a titanium substrate 1, a dense protective intermediate layer 2 and an active surface layer 3; wherein the dense protective intermediate layer 2 is a titanium dioxide layer, the titanium substrate 1 is a metal titanium plate with a thickness of 1.2mm, and the active surface layer 3 is IrO 2 layer; TiO2 layer and IrO 2 Layers are generated synchronously in situ.

[0040] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0041] 1) Cut a metal titanium plate with a thickness of 1.2mm into a specification of 5cm×5cm, then polish it with sandpaper, degrease and clean it in a boiling 5wt% NaOH solution for 1h, and then etch it in a boiling 15wt% oxalic acid solution for 1h, Finally, it was rinsed with deionized water to obtain a titanium metal plate with a clean surface.

[0042] 2) Put the metal titanium plate wit...

Embodiment 2

[0047] A titanium-based composite anode of the present invention, such as figure 1 As shown, it includes a titanium substrate 1, a dense protective intermediate layer 2 and an active surface layer 3; wherein the dense protective intermediate layer 2 is a titanium dioxide layer, the titanium substrate 1 is a metal titanium plate with a thickness of 1.2mm, and the active surface layer 3 is MnO2 layer; TiO2 layer and MnO 2 Layers are generated synchronously in situ.

[0048] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0049] 1) Cut a metal titanium plate with a thickness of 1.2mm into a size of 2cm×2cm, then polish it with sandpaper, wash it with alkali in a boiling 8wt% NaOH solution for 1h, and then etch it in a boiling 15wt% oxalic acid solution for 1h , and finally rinsed with deionized water to obtain a titanium metal plate with a clean surface.

[0050] 2) Put the metal titanium plate with clean surface ...

Embodiment 3

[0054] A titanium-based composite anode of the present invention, such as figure 1 As shown, it includes a titanium substrate 1, a dense protective intermediate layer 2 and an active surface layer 3; wherein the dense protective intermediate layer 2 is a titanium dioxide layer, the titanium substrate 1 is a metal titanium plate with a thickness of 1.2mm, and the active surface layer 3 is MnO 2 layer; TiO2 layer and MnO 2 Layers are generated synchronously in situ.

[0055] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0056] 1) Cut a metal titanium plate with a thickness of 1.2mm into a size of 2cm×2cm, then polish it with sandpaper, wash it with alkali in a boiling 12wt% NaOH solution for 1h, and then etch it in a boiling 12wt% oxalic acid solution for 1h , and finally rinsed with deionized water to obtain a titanium metal plate with a clean surface.

[0057] 2) Put the metal titanium plate obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com