Massproduction method of single crystal cobalt-free lithium-rich manganese-based binary material precursor

A technology of cobalt, lithium-rich manganese-based, binary materials, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve problems such as unfavorable industrialization and complex processes, and achieve the effect of reducing raw material costs and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

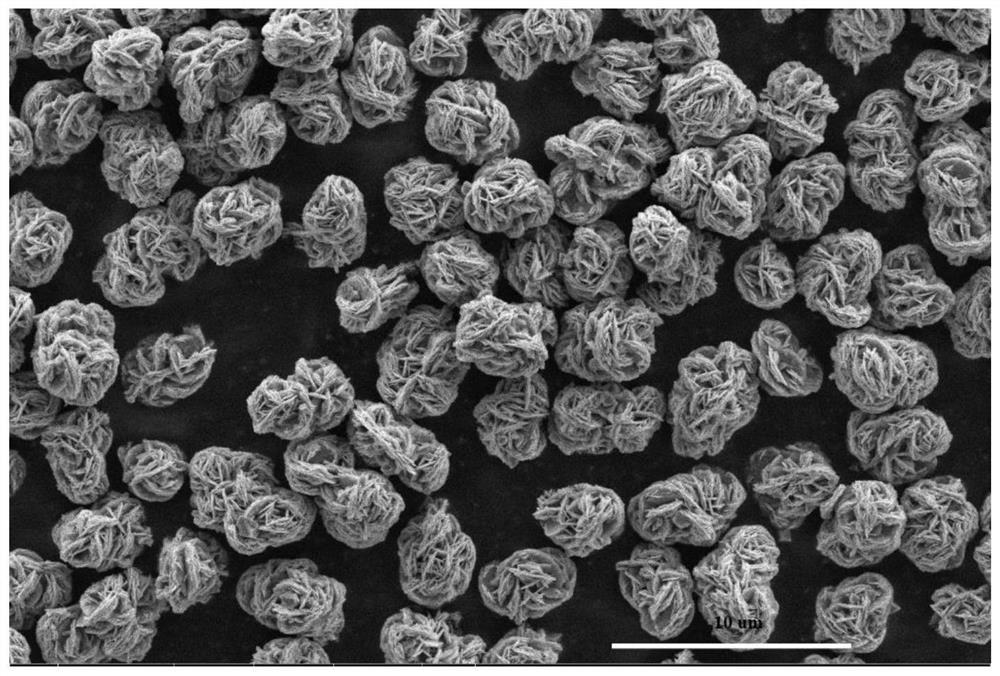

Embodiment 1

[0025] Step 1, nickel sulfate, manganese sulfate are mixed with the aqueous solution A of 2mol / L metal concentration by the ratio of metal molar ratio 20:80, adopt the NaOH solution of 32% as precipitation agent B, the ammoniacal liquor of 17% is as complexing agent C, 20g / L sodium sulfite solution is used as reducing agent D.

[0026] Step 2. Prepare the bottom solution and feed N2 as a protective gas. The pH of the bottom solution is 11.4-11.6, the ammonia concentration is maintained at 3-4g / L, the temperature is controlled at 34-36°C, and the stirring speed is controlled at 400rpm.

[0027] Step 3. Pump solution A, solution B, solution C and solution D into the reactor at the same time at the speed of 300L / h, 80L / h, 20L / h, 30L / h, keep the pH at 11.0-11.2, supernatant liquid ammonia The concentration is 3-4g / L, the temperature is 34-36°C, and the stirring speed is 400rpm.

[0028] Step 4: stop feeding after D50 reaches 3.5um, perform centrifugal washing, drying, screening, ...

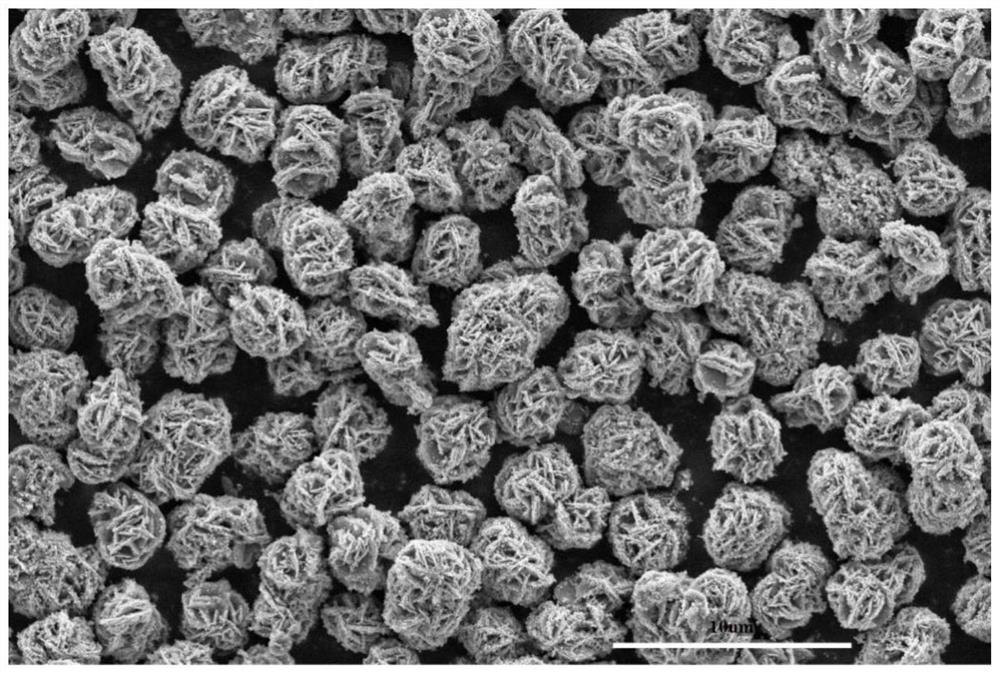

Embodiment 2

[0031] Step 1, nickel sulfate, manganese sulfate are mixed with the aqueous solution A of 2mol / L metal concentration by the ratio of metal molar ratio 30:70, adopt the NaOH solution of 32% to be precipitation agent B, the ammoniacal liquor of 17% is as complexing agent C, 20g / L sodium sulfite solution is used as reducing agent D.

[0032] Step 2. Prepare the bottom solution and feed N2 as a protective gas. The pH of the bottom solution is 11.6-11.8, the ammonia concentration is maintained at 4-5g / L, the temperature is controlled at 44-46°C, and the stirring speed is controlled at 350rpm.

[0033] Step 3. Pump solution A, solution B, solution C and solution D into the reactor at the same time at the speed of 450L / h, 120L / h, 40L / h, 45L / h, keep the pH at 11.2-11.4, supernatant liquid ammonia The concentration is 4-5g / L, the temperature is 44-46°C, and the stirring speed is 350rpm.

[0034] Step 4: stop feeding after D50 reaches 3.6um, perform centrifugal washing, drying, sieving...

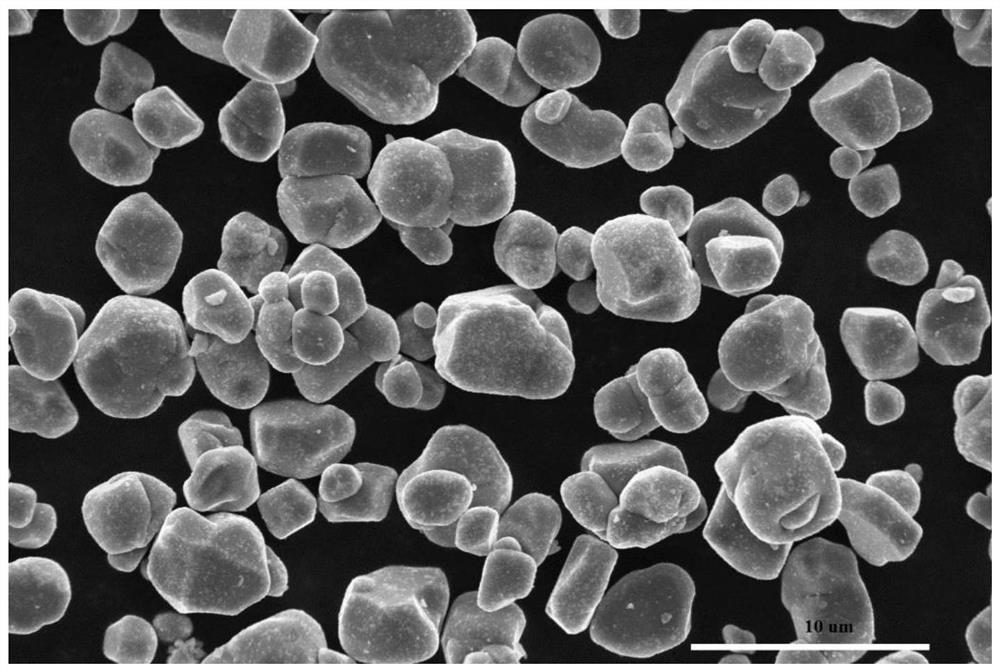

Embodiment 3

[0036] Step 1, nickel sulfate, manganese sulfate are mixed with the aqueous solution A of 2mol / L metal concentration by the ratio of metal molar ratio 40:60, adopt the NaOH solution of 32% as precipitation agent B, the ammoniacal liquor of 17% is as complexing agent C, 20g / L sodium sulfite solution is used as reducing agent D.

[0037] Step 2. Prepare the bottom solution and feed N2 as a protective gas. The pH of the bottom solution is 11.8-12.0, the ammonia concentration is maintained at 6-8g / L, the temperature is controlled at 49-51°C, and the stirring speed is controlled at 320rpm.

[0038] Step 3. Pump solution A, solution B, solution C and solution D into the reaction kettle at the same time at the speed of 600L / h, 158L / h, 60L / h, 60L / h, keep the pH at 10.8-11.0, supernatant liquid ammonia The concentration is 6-8g / L, the temperature is 49-51°C, and the stirring speed is 320rpm.

[0039] Step 4: stop feeding after D50 reaches 3.8um, perform centrifugal washing, drying, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com