Device and method for welding optical fibre and end cap

An optical fiber end and fusion splicing technology, which is applied in the optical fiber end cap fusion splicing device and its fusion splicing field, can solve the problems that the optical fiber cannot be spliced with a large-diameter quartz end cap, etc., and achieve the effect of improving the quality of fusion splicing, improving quality, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

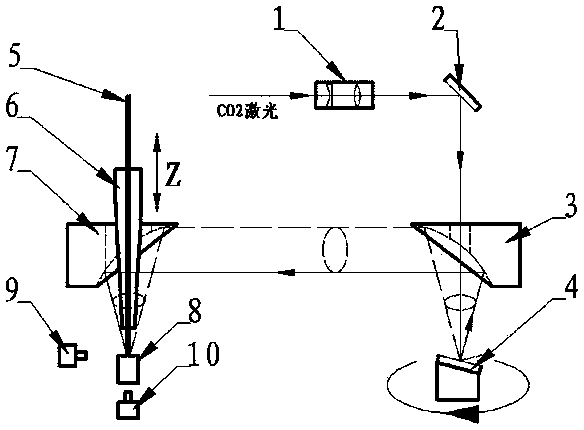

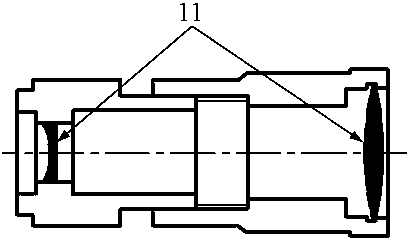

[0038] see Figure 1~6 , an optical fiber end cap fusion splicing device related to the present invention, the device includes the following components:

[0039] A beam expander and collimator mirror 1, used to expand and collimate the laser light emitted by the laser generator (preferably, using a CO2 laser generator), so as to eliminate the influence of the laser divergence angle and obtain a laser beam with better collimation , and the light spot can be adjusted to adapt to the splicing of different sizes of fiber end caps;

[0040] A reflector 2, used to reflect and redirect the laser beam exiting the beam expander and collimator mirror 1;

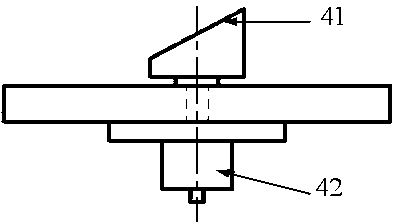

[0041] A rotating mirror 4, which is used to expand the laser light reflected by the mirror 2 into a conical beam;

[0042] An off-axis parabolic reflector 3 is used to reflect the conical light beam formed by the reflection and expansion of the rotating reflector 4 into an annular light beam again;

[0043] An off-axis parabolic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com