Production of alcohol fuel

A production method and technology of fuel ethanol, which can be applied to fuels, biofuels, liquid carbon-containing fuels, etc., and can solve problems such as excessive consumption, depletion, and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

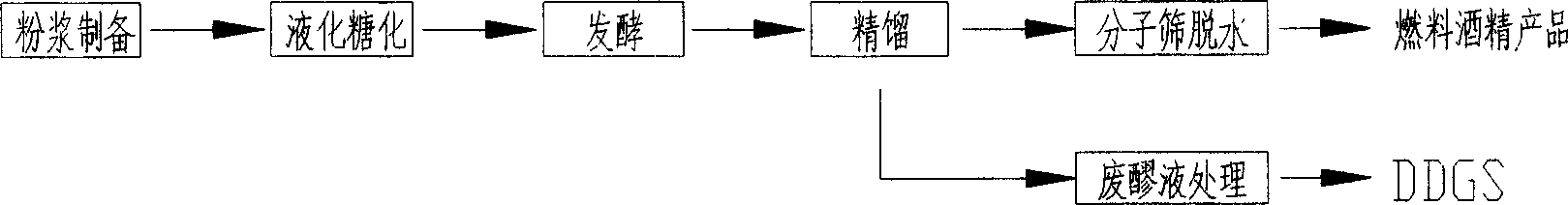

[0029] The process of producing fuel ethanol from starchy raw materials such as corn, rice, wheat, sorghum, dried potato, and cassava, such as figure 1 As shown, in this embodiment, corn is used as raw material to produce fuel ethanol, and the process of other starchy raw materials is roughly the same.

[0030] The raw corn is crushed, and the crushing method can be wet crushing, dry crushing, or semi-dry crushing. Stir with water, adjust the concentration of the powder slurry to be 31% of dry matter content, and the pH value is 4.5. Add amylase, the total amount of amylase added is 2.5 units / gram of raw material, first add 25% of the total amount. Steam cooking is added, the cooking temperature is 80°C, and the cooking time is 30 minutes. After cooking, the starch slurry is sent to the jet liquefier for jet liquefaction. The heating temperature of the material in the jet liquefier is 105°C, and the residence time is 15 minutes to complete a liquefaction process. After com...

Embodiment 2

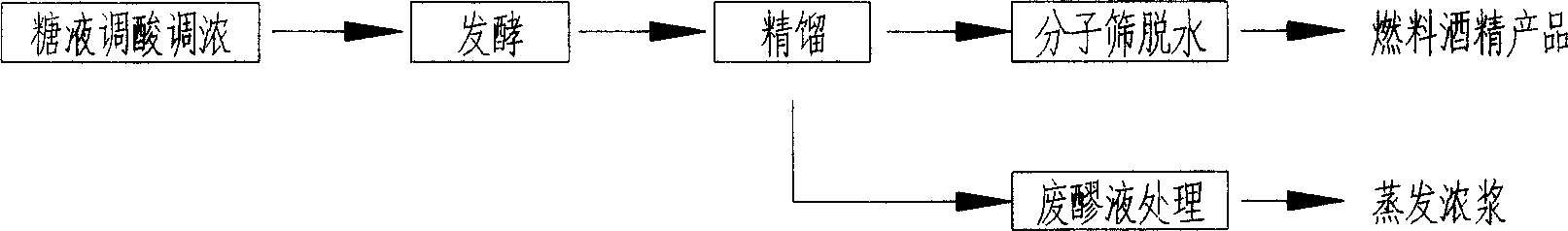

[0035] The process of producing fuel ethanol from sugary raw materials such as beet juice, sugarcane juice, molasses, etc. figure 2 As shown, the present embodiment is the production of fuel ethanol with molasses as raw material.

[0036] The raw material molasses is sent to the pretreatment tank after precipitation and slag removal, and water is added to adjust the sugar concentration to 24%, and acid is added to adjust the pH value of the sugar liquid to 3.5. A small part of the sugar solution with adjusted concentration and acidity is sent to the distiller's multiplication tank, and most of it is sent to the first tank of the fermentation tank. After the active dry yeast is activated in the activation tank, it is sent to the distiller's mother breeding tank for proliferation and cultivation. The qualified distiller's mash is continuously sent to the first tank of the fermenter.

[0037] The implementation process of fermentation process, rectification process and molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com