Method for filtering, washing and separating crude terephthalic acid by using oxidizing unit of fine terephthalic acid device

The technology of purified terephthalic acid and crude terephthalic acid is applied in the field of energy saving and consumption reduction in the oxidation unit of purified terephthalic acid, and can solve the problems of leakage of filtrate, high energy consumption, easy to affect normal production, etc. The effect of reducing the number of equipment, shortening the process, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

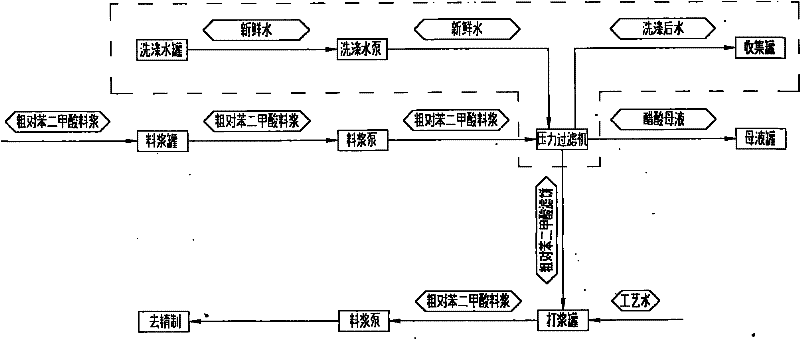

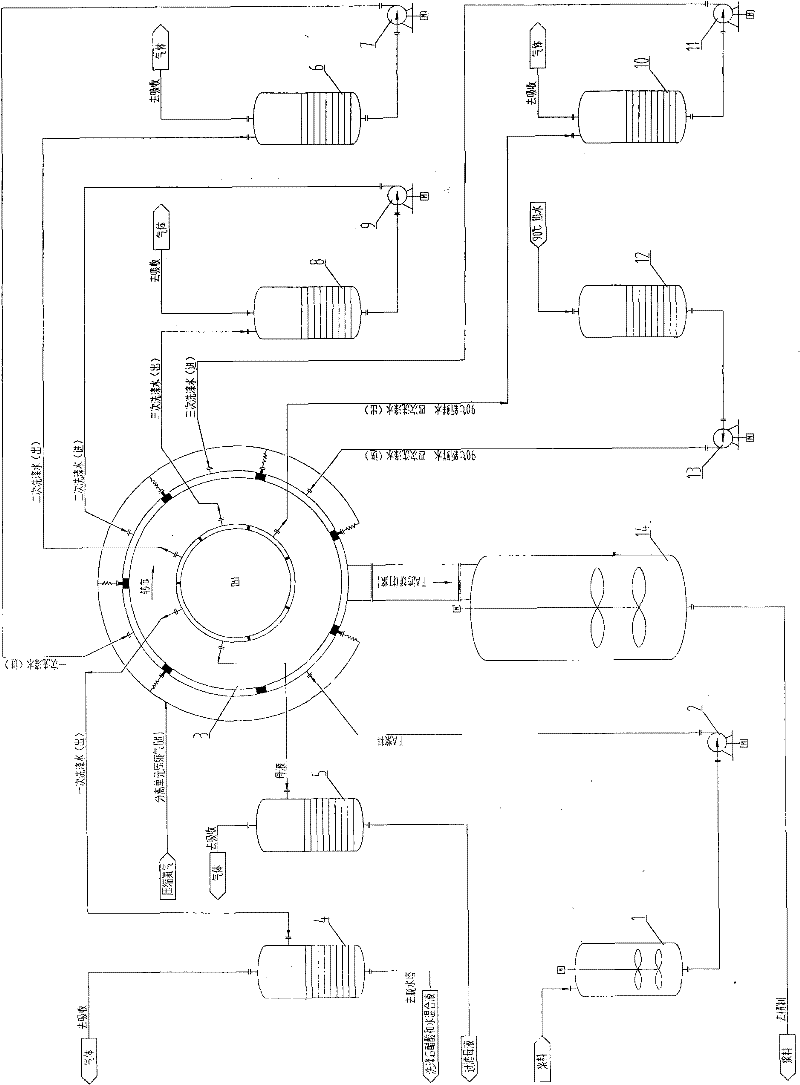

[0028] The pressure filter 3 used in the present invention is a continuous pressure filter that integrates filtration, washing and drying (patent number: 200 2 0144208.5) applied by Tianhua Chemical Machinery and Automation Research and Design Institute. (PTA) device oxidation unit process technology has been used.

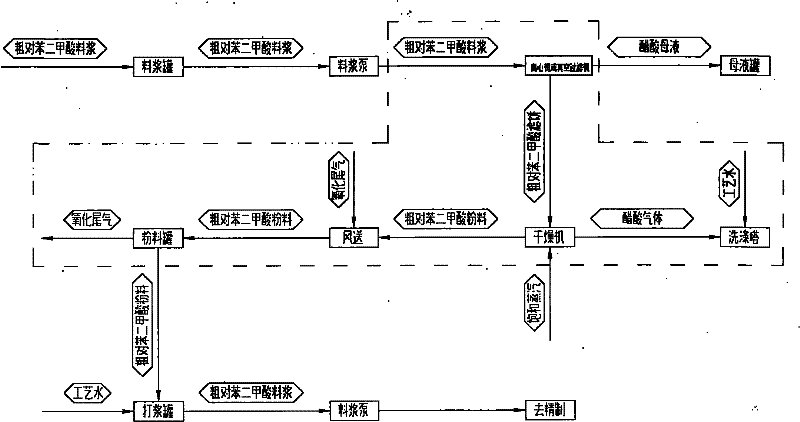

[0029] Attached below Figure 2-3 , further describe the flow process of the "filtration, washing" process of TA suspension:

[0030] A method for "filtering, washing, and separating" the crude terephthalic acid suspension in the oxidation unit of a purified terephthalic acid plant, the steps comprising:

[0031] a. The TA slurry in the TA slurry tank 1 is pressurized to 0.3MPa(G) by the TA slurry pump 2 and then enters the filter unit room of the pressure filter 3, and the pressure filter 3 rotates centripetally by means of frequency conversion speed regulation . The annular area between the drum and the casing of the pressure filter 3 is sealed with a special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com