Dispersed dye mixture and application thereof

A technology of disperse dyes and mixtures, which is applied in the field of sub-dye, which can solve the problems of poor light fastness of dyes, achieve excellent rubbing fastness and washing fastness, good compatibility, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

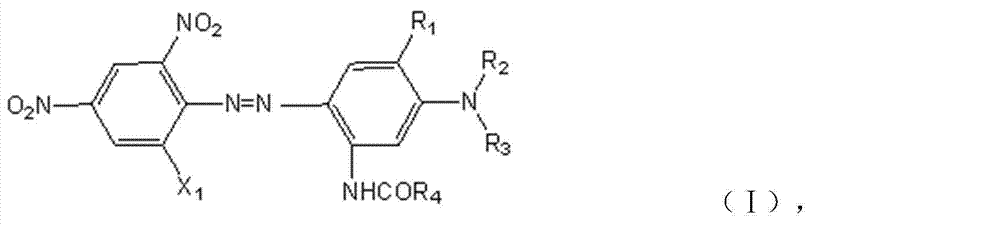

Image

Examples

Embodiment 1

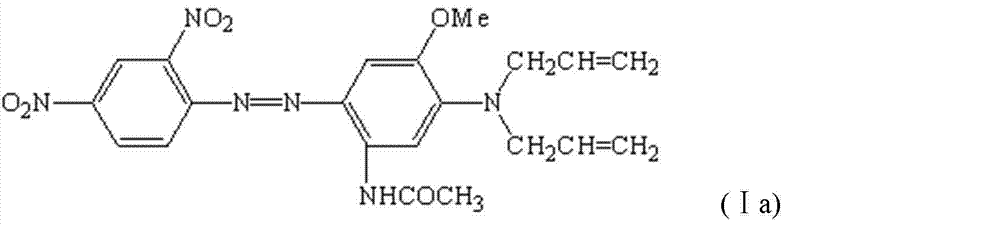

[0037] a) 8 grams of the following formula (Ia) dye:

[0038]

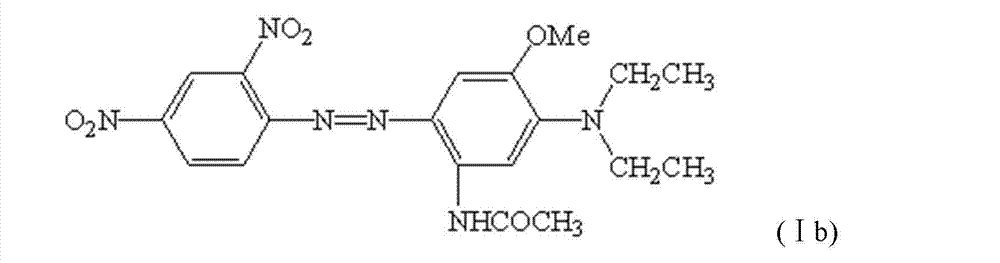

[0039] and 9 grams of a dye of formula (Ib):

[0040]

[0041] and 8.2 g of a dye of formula (Im):

[0042]

[0043] and 8.4 g of a dye of formula (IIa):

[0044]

[0045] Mix the (Ia), (Ib) and (Im) components of component A with the (IIa) component of component B to make disperse dye mixture 1, then use 112 ml of water and 14.4 g of dispersant MF in sand mill Grind together in the machine for 3 hours, and then spray dry (inlet temperature 130°C, outlet temperature 60°C) to obtain a powder (about 50 grams) that is a solid dye product 1 made of disperse dye mixture 1. The dye product 1 is easy to disperse into the water.

Embodiment 2~33

[0047] As shown in Table 1, mix the components of component A with the components of component B to make disperse dye mixtures 2~33, and then mix them together with the water used in Table 1 and the additives used in the sand mill Grind in medium for 4 hours, and then spray dry (inlet temperature 130°C, outlet temperature 60°C) to obtain powder (about 50 grams) that is solid dye product 2~33 made of disperse dye mixture 2~33.

[0048] Table 1

[0049]

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com