Membraneless electrodeionization method and system thereof, capable of directly exhausting oxygen gas and hydrogen gas outwards are

An electrodeionization and gas technology, applied in the direction of ion exchange, electron exchanger, ion exchange regeneration, etc., can solve the problems of resin layer resistance rise, regeneration voltage rise, waste of energy consumption, etc., to achieve regeneration voltage drop, easy maintenance, Avoid cumulative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

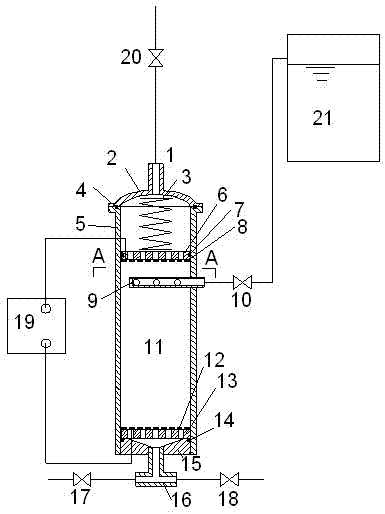

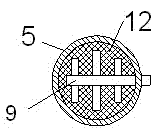

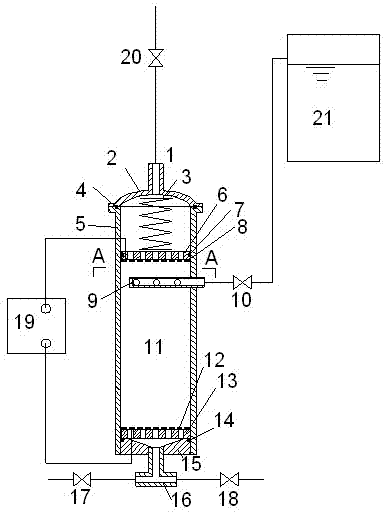

[0034] The reverse osmosis effluent with a conductivity of about 15μs / cm adopts figure 1 The shown hydrogen and oxygen gas is directly discharged to the membraneless electrodeionization device for treatment. The mixed resin of yin and yang is adopted, the volume ratio of yin and yang resin is 3:1, and the height of the resin layer is 0.88m. The operating conditions are as follows: the current density of the direct current for regeneration is 200A / m 2 ; The average voltage is 1100V; the velocity of regeneration water is 15 m / h; the regeneration time is 1.0h; the velocity of treatment water is 15m / h. The operation results are as follows: the conductivity of the effluent after treatment is 0.057-0.067 μs / cm; the average conductivity of the concentrated water produced during the regeneration process is 255 μs / cm; the water recovery rate is about 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com