Hanging net assembling system of concrete prefabricated mold

An assembly system and concrete technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome operation, low work efficiency, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

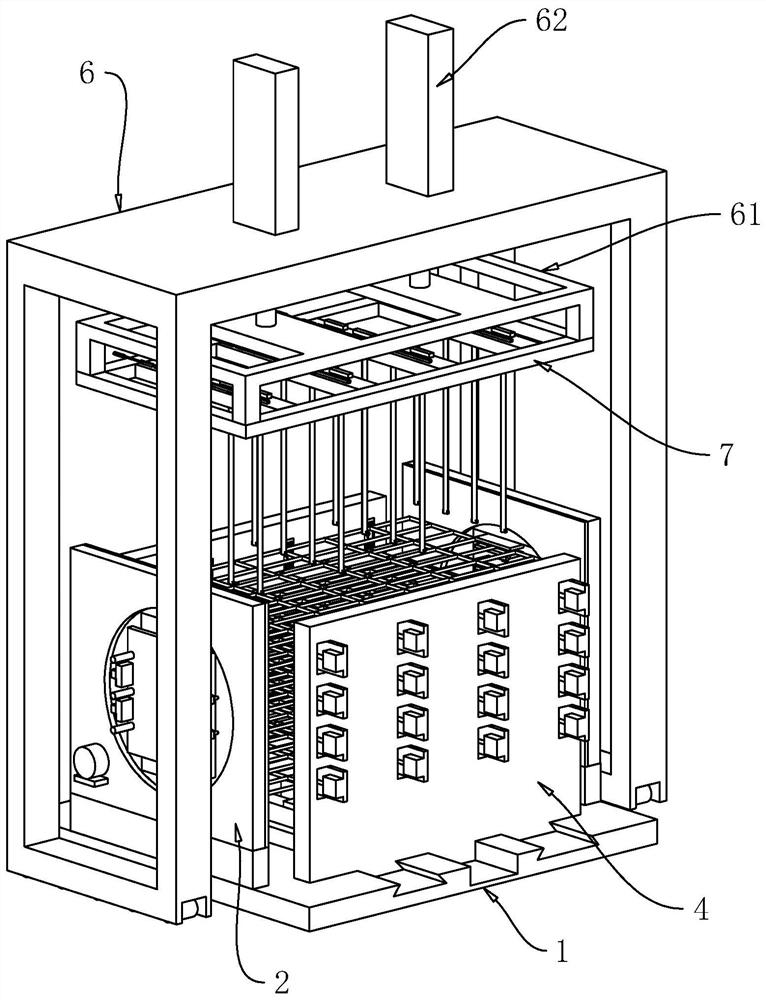

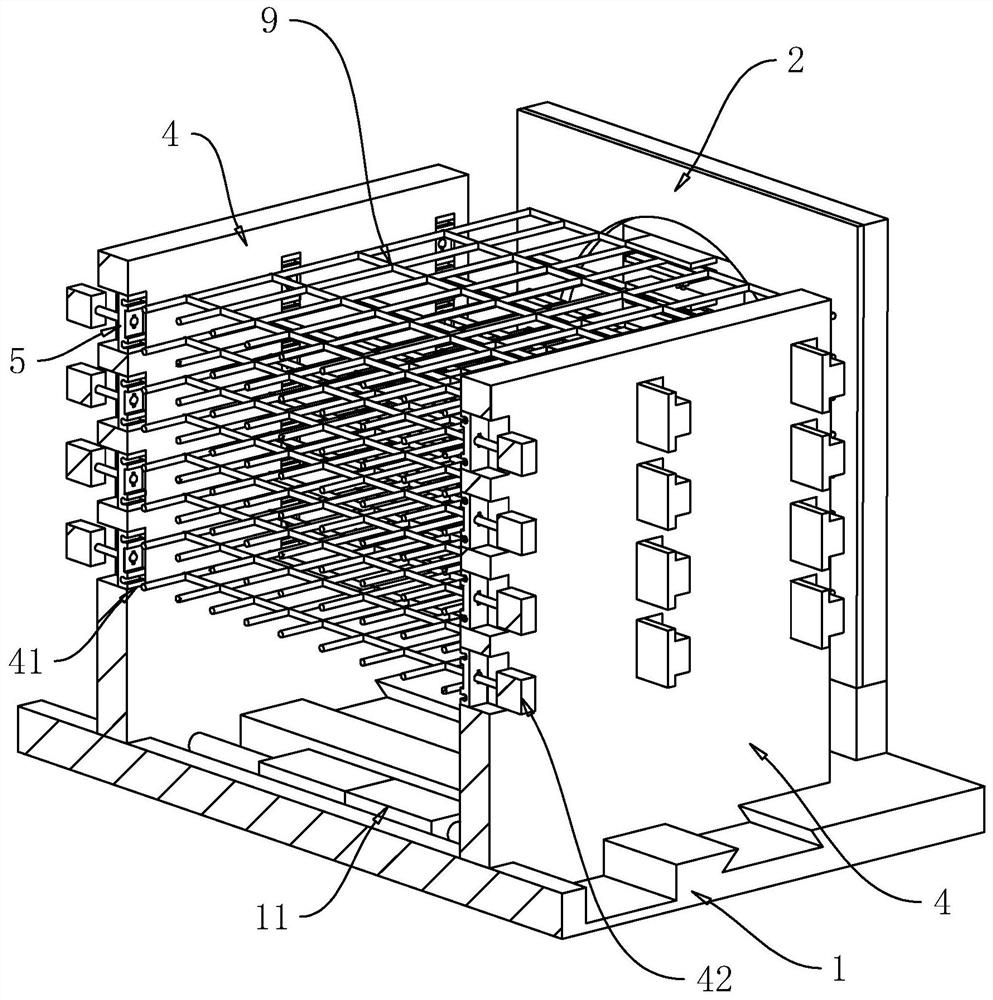

[0048]Contraction belowFigure 1-7Further detailed description of the present application.

[0049]The present application discloses a hanging net assembly system for concrete prefabricated molds.

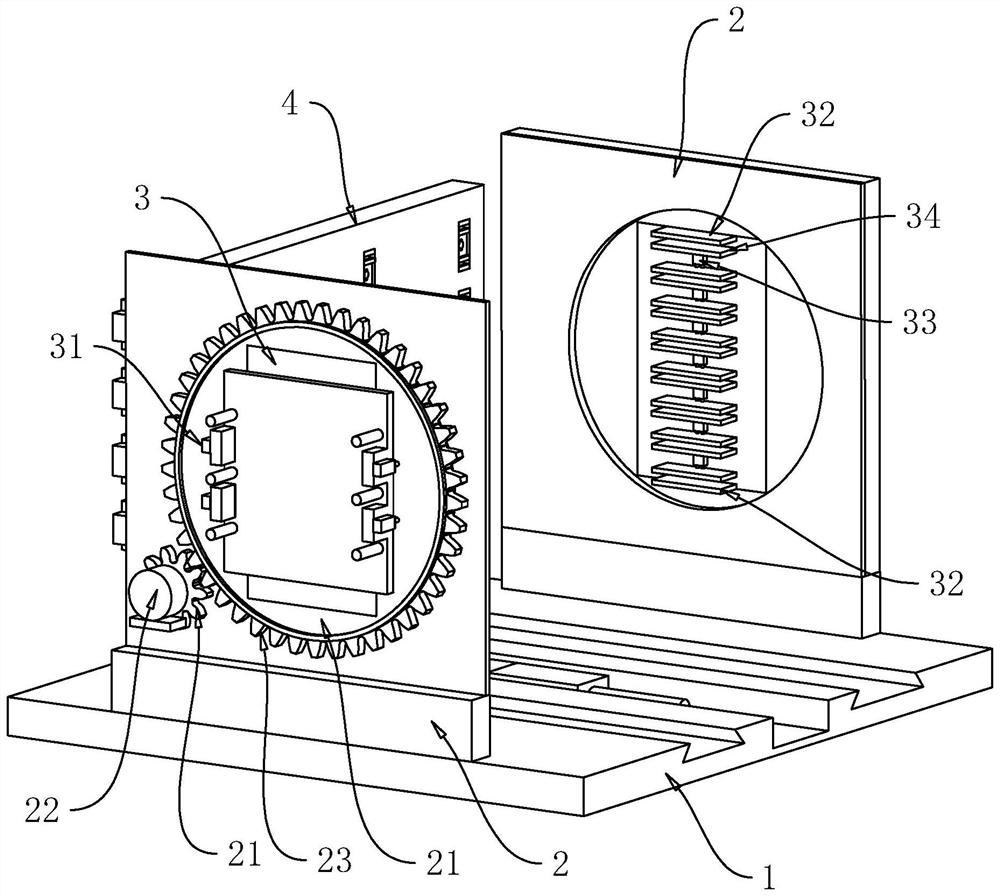

[0050]Referfigure 1 withfigure 2 , A hanging mesh assembly system of a concrete prefabricated mold, including a chassis 1, a chassis 1 having a rectangular shape, and both ends of the chassis 1 are vertically fixed with a fixing frame 2, and the fixed frame 2 is rotated and connected to the rotating frame. 21, the axis of the two rotating frame 21 is the same as the length direction of the chassis 1, and the axis of the two rotating frame 21 is in the same straight line, and the drive gear 21 is fixed to the circumferential surface of the rotating frame 21, and the fixing frame 2 corresponds to the rotating frame 21. On one end, the servo motor 22 is fixed, and the output shaft of the servo motor 22 is solid to have the driven gear 23, and the drive gear 21 engages the driven gear 23. When work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com