Tool holder

A tool holder and tool technology, which is used in the manufacture of tools, mechanical equipment, tool holders, etc., can solve the problems of limiting the possibility of using the tool holder and the total length of the axial direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

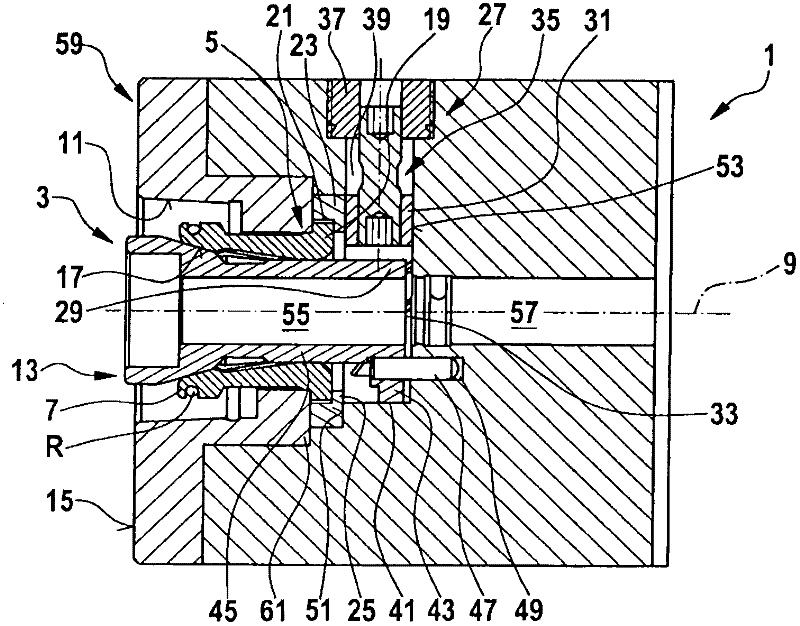

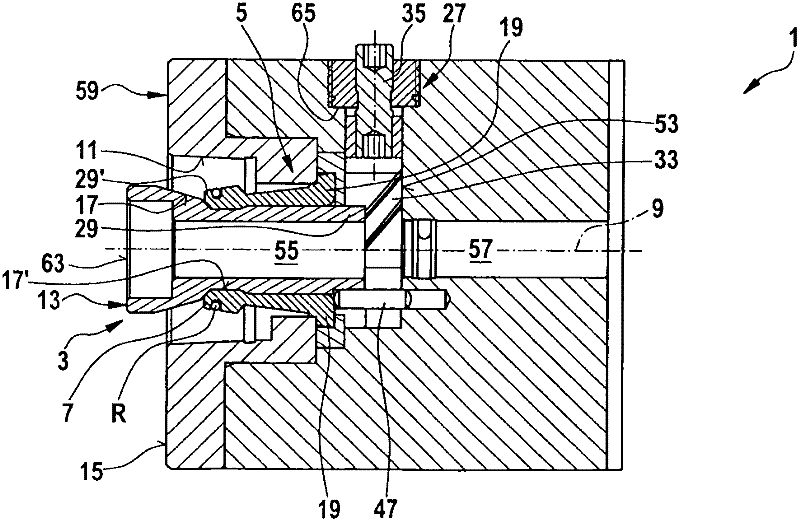

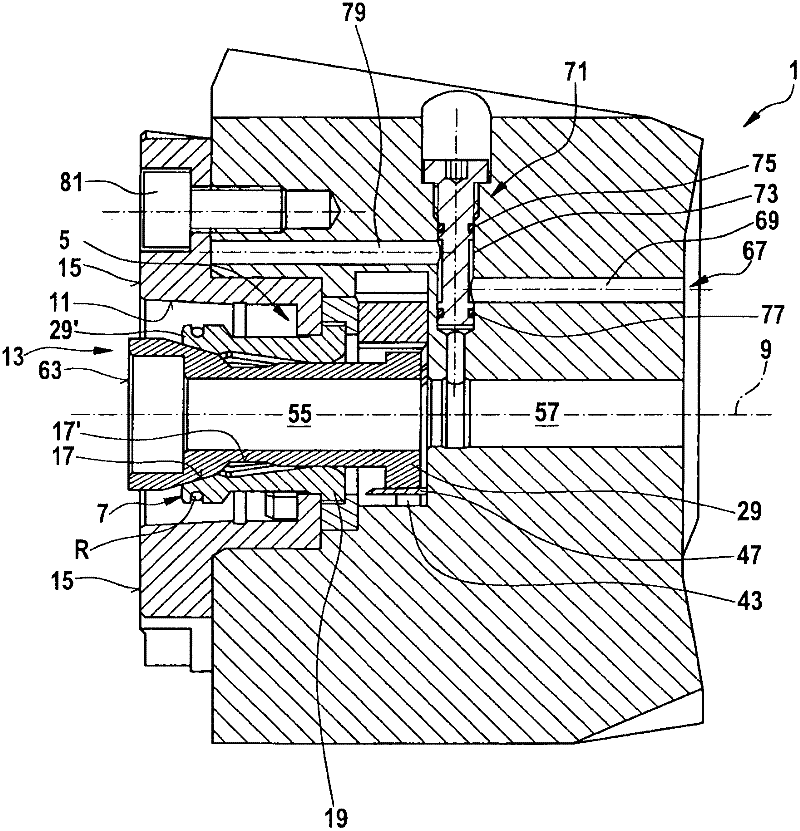

[0029] figure 1 A tool holder 1 with a quill holder 3 is shown. The hollow shaft taper shank clamp 3 includes a clamping device 5 , and the clamping device 5 includes at least one clamping chuck 7 . In order to be able to introduce the clamping force as uniformly as possible on the hollow shaft of the tool (not shown) that should be clamped and fixed in the tool holder 1, the clamping device usually has a plurality of The clamping jaws 7 are arranged at the same distance from one another. Said clamping chuck 7 engages in a hollow shaft of a tool (not shown) and cooperates with a clamping surface provided on the inner side of the hollow shaft, said clamping surface being formed so as to remove substantially radially from the clamping The force exerted by the clamping chuck 7 - that is to say the force acting perpendicularly to the central axis 9 - is resolved into a force component which acts radially outward and presses the hollow shaft taper against the receiving surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com