Noise barrier especially for a high-speed railway line

A technology for high-speed railways and sound barriers, applied in noise absorption devices, buildings, etc., can solve the problem of high installation cost of sound insulation components, and achieve the effect of reliable assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

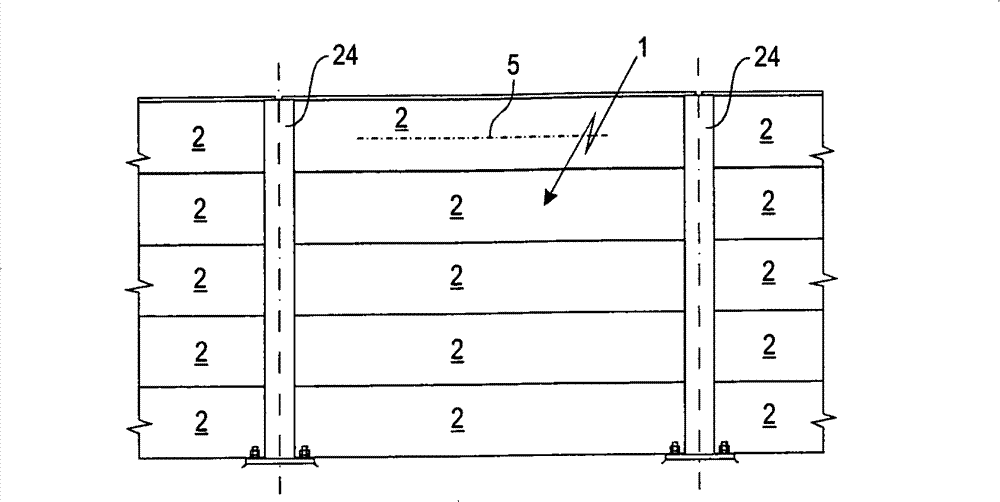

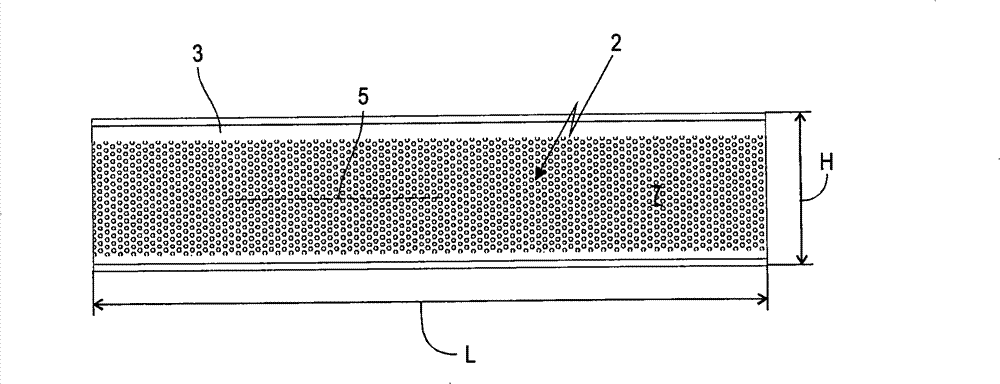

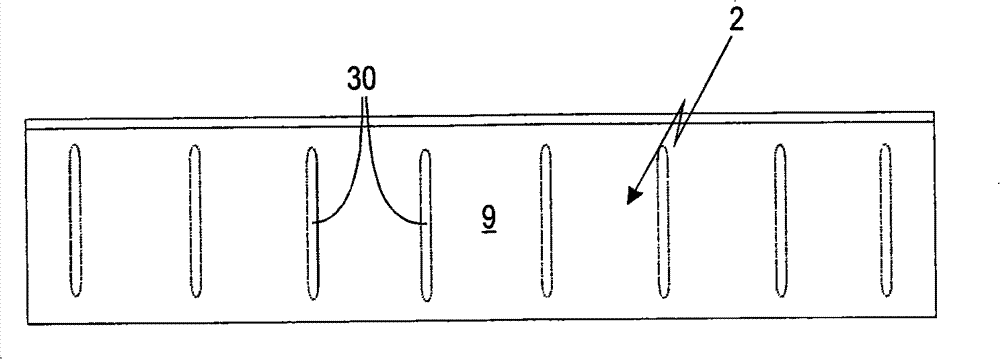

[0029] figure 1 A sound barrier 1 according to the invention is shown in side view, which is formed from a plurality of uprights 24 with panel-type sound insulation elements 2 located therebetween. In this exemplary embodiment, the columns 24 each have a screw flange at their lower end, by means of which the columns are fastened to a base not shown in detail. Expediently, the columns 24 can also be inserted into the foundation, cast in concrete or fixed in some other way. Each sound insulation element 2 is designed as an elongated plate which extends along a longitudinal axis 5 . The longitudinal axis 5 runs horizontally between the columns 24 . Five sound insulation elements 2 are respectively stacked between two adjacent columns 24 . Other quantities may also be suitable. For installation, firstly the column 24 is erected, and then the sound insulation element 2 is inserted into the position of the column 24 from above. Image 6 Between the sides 27, 28 shown in and sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com