Efficient energy-saving jet aerator

A jet aeration, high-efficiency and energy-saving technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of unsatisfactory dissolution and mixing effects, low air flotation or aeration efficiency, and large bubble diameter and other problems, to achieve the effect of high gas-liquid mass transfer efficiency, enhanced shearing effect, and strong suction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

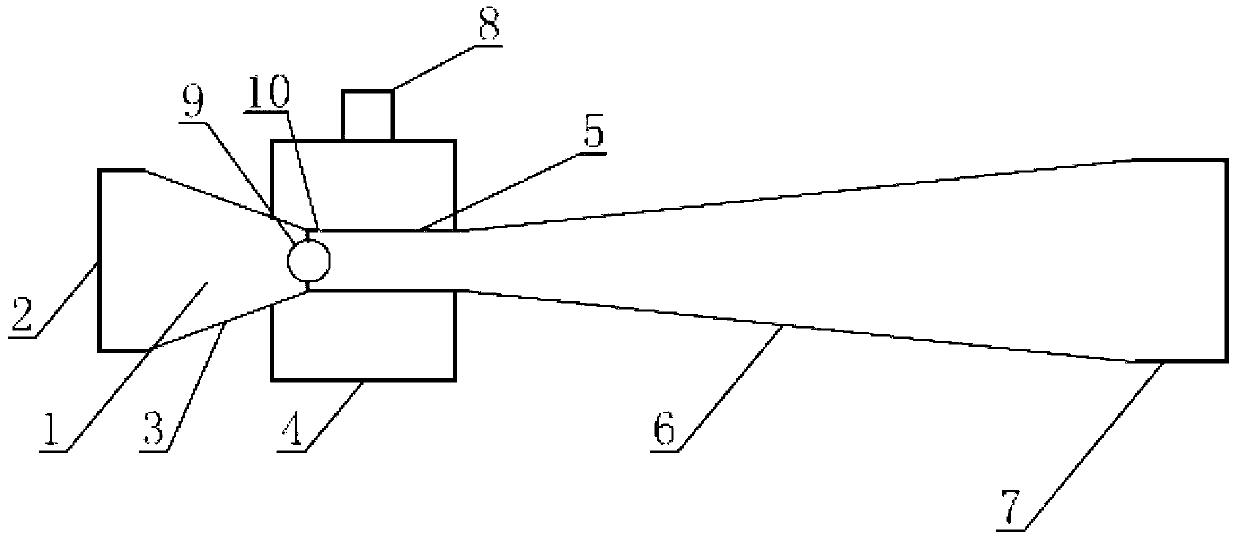

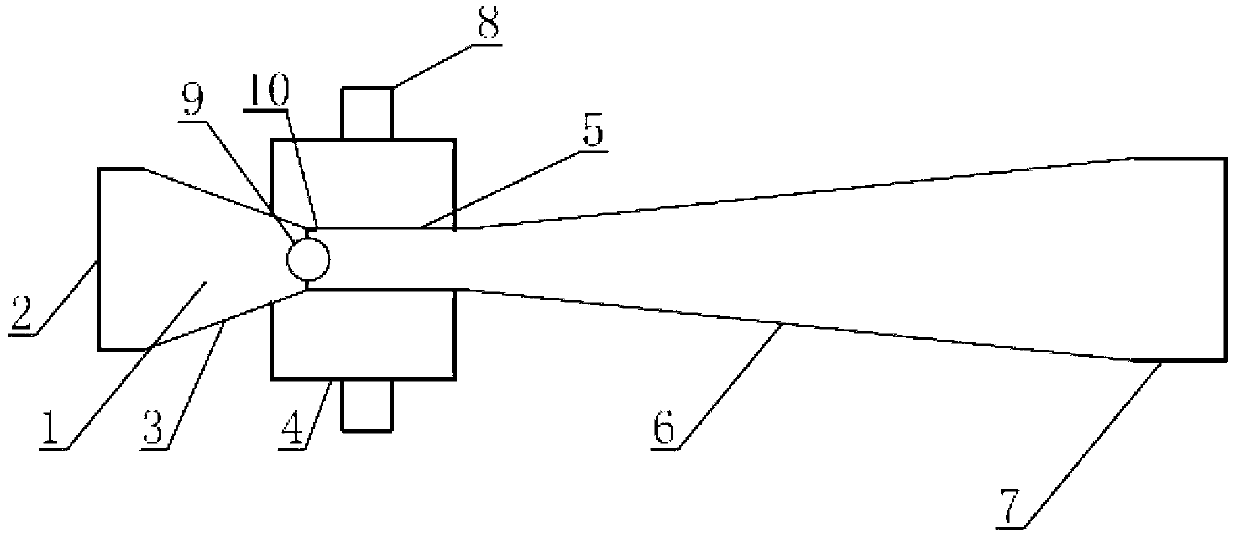

[0026] Such as figure 1 As shown, the high-efficiency energy-saving jet aerator 1 includes a water inlet pipe 2, a reducer pipe 3, a throat pipe 5, an expander pipe 6 and a gas-liquid mixing outlet pipe 7, and the diameter of the throat pipe is smaller than the water inlet pipe and the gas-liquid mixing outlet pipe. , the throat pipe is connected to the water inlet pipe through a reducer, and the gas-liquid mixing outlet pipe is connected through a gradual expansion section. There is an air suction port 10 on the outer wall of the throat pipe. The position, that is, the position of the spout, is fixedly provided with a water flow cutting body 9.

[0027] A gas chamber 4 is also provided outside the throat, and a gas inlet pipe 8 communicating with the outside atmosphere is provided on the gas chamber.

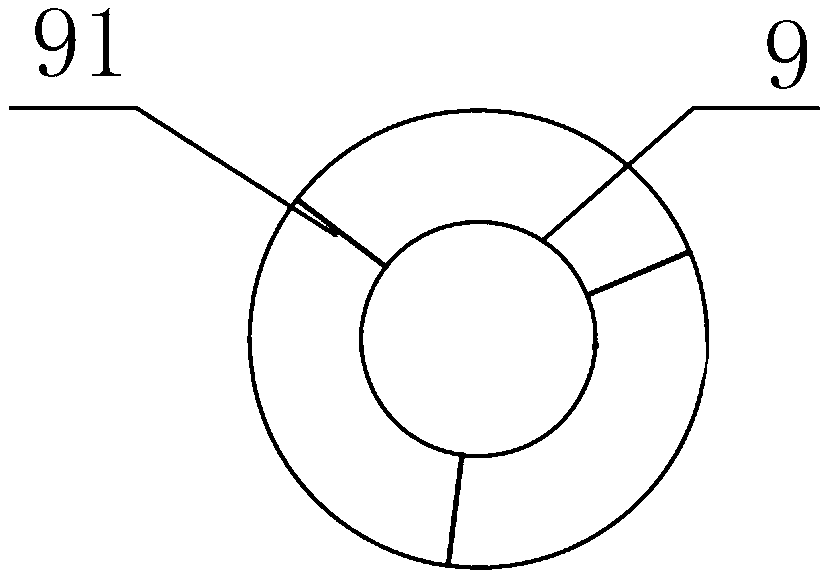

[0028] The water flow cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com