Efficient disc type ditcher

A disc-type, ditching machine technology, applied in the direction of excavation/covering trenches, planting methods, earth movers/shovels, etc., can solve the problem of easily damaged ditching scimitars, ditching scimitars colliding with the ground, etc. Problems, to achieve the effect of reducing damage, reducing instantaneous force, and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

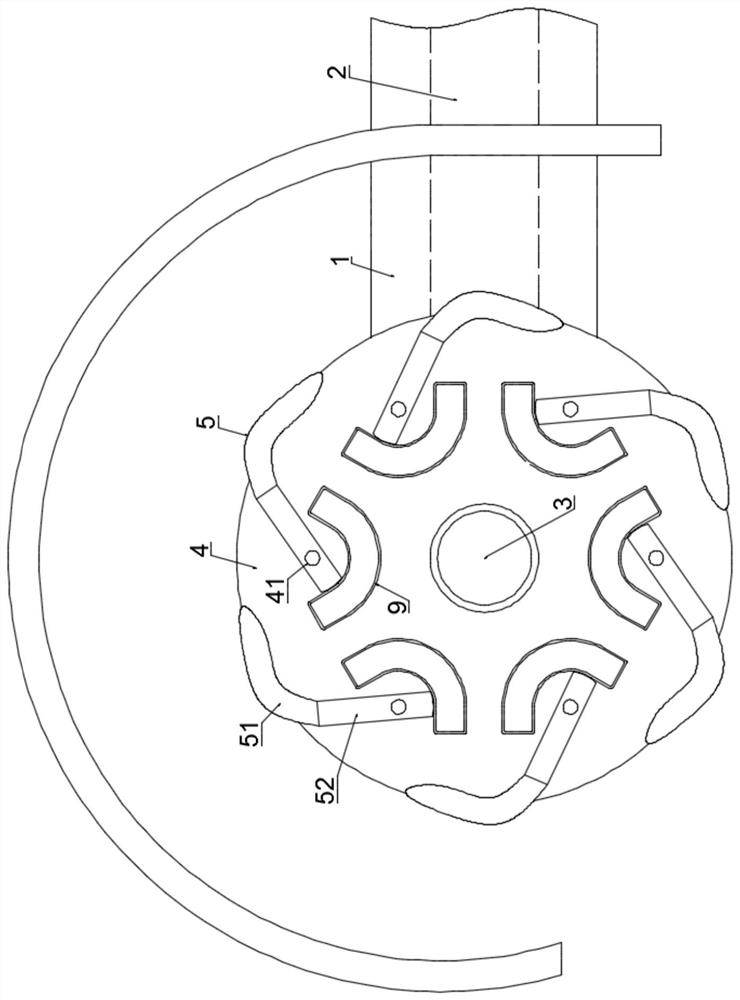

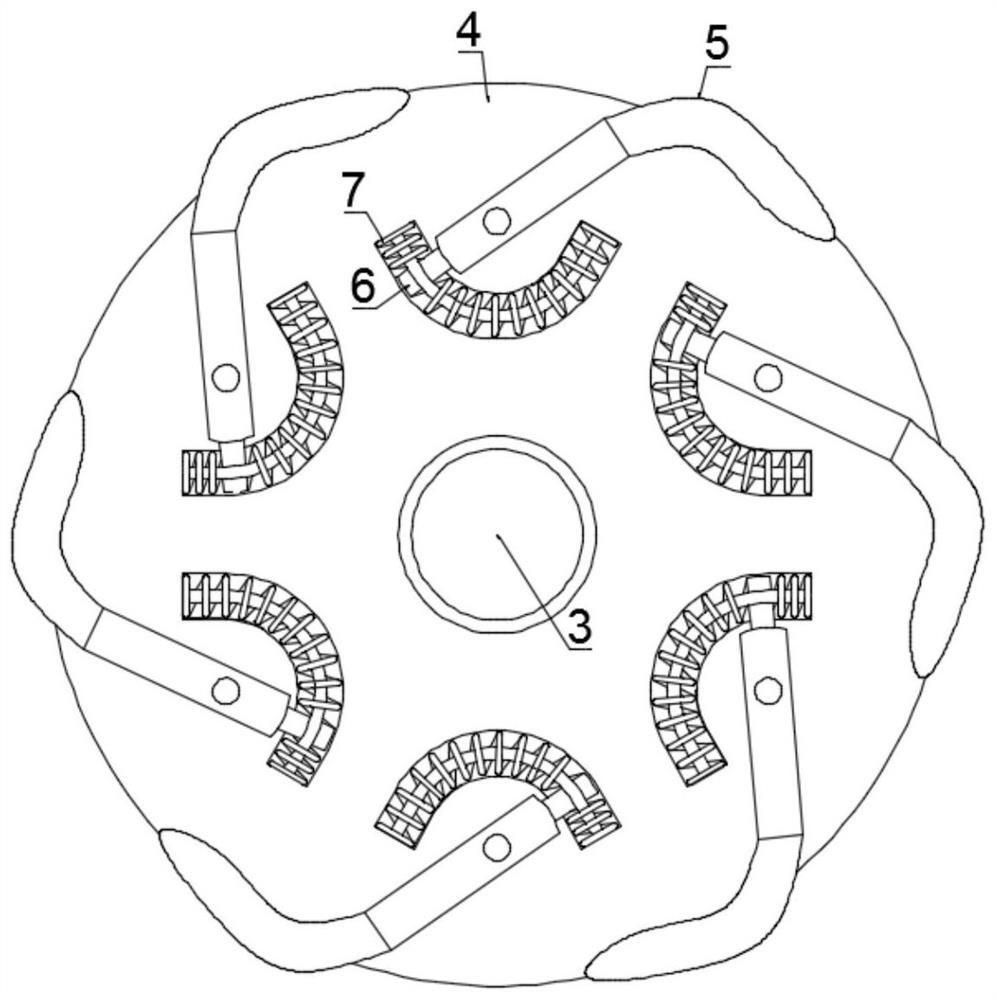

[0026] refer to Figure 1-6 , a high-efficiency disc type trencher, including a frame 1, a drive assembly 2 is fixedly connected to the middle of the frame 1, the drive assembly 2 adopts existing drive equipment, and the output ends of the drive assembly 2 are coaxially fixed The drive shaft 3 is connected, and the output end of the drive assembly 2 drives the two drive shafts 3 to rotate.

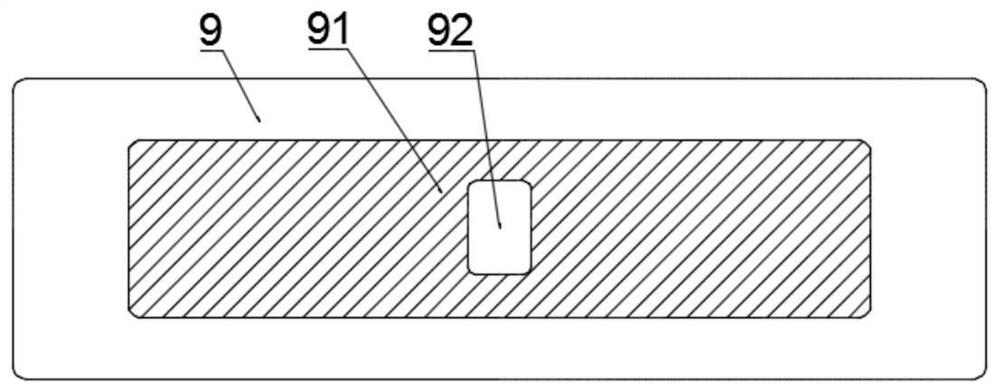

[0027] Both ends of the two driving shafts 3 are rotatably connected to the frame 1, and the middle part is coaxially fixedly connected with a ditching cutter head 4, and the sides of the two ditching cutter heads 4 facing away from each other are connected with a plurality of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com