Cookie machine integrating knife cutting and line cutting

A cookie machine and knife cutting technology, applied in the field of cookie machines, can solve the problem that the cookie machine cannot meet the cutting process, etc., and achieve the effect of high cutting efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

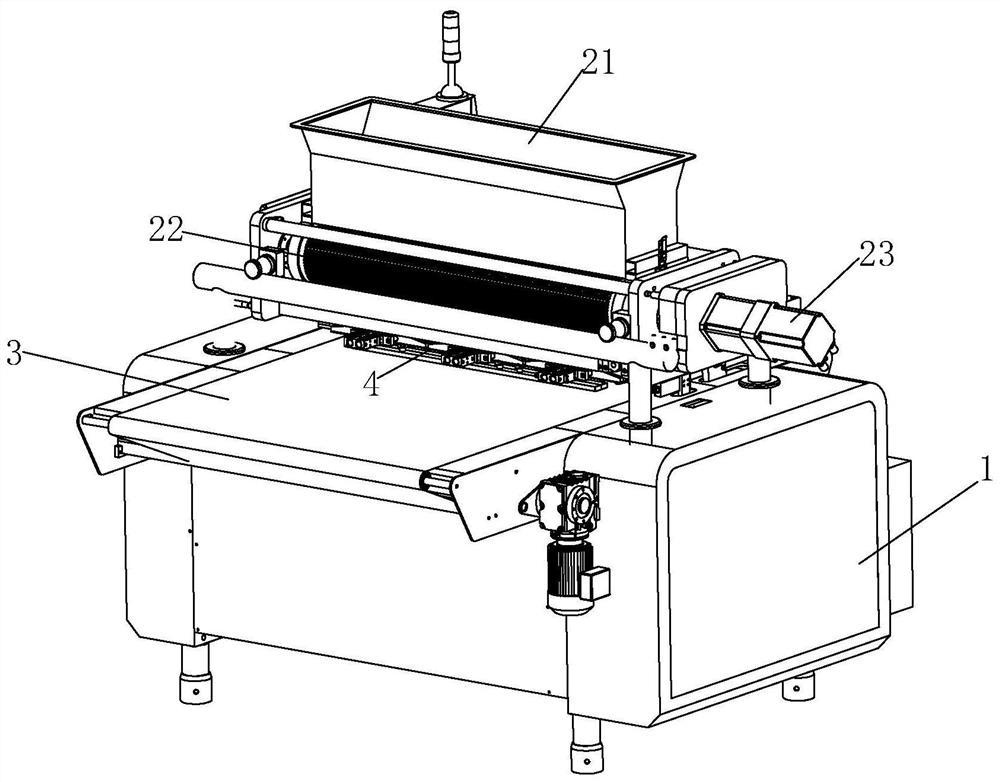

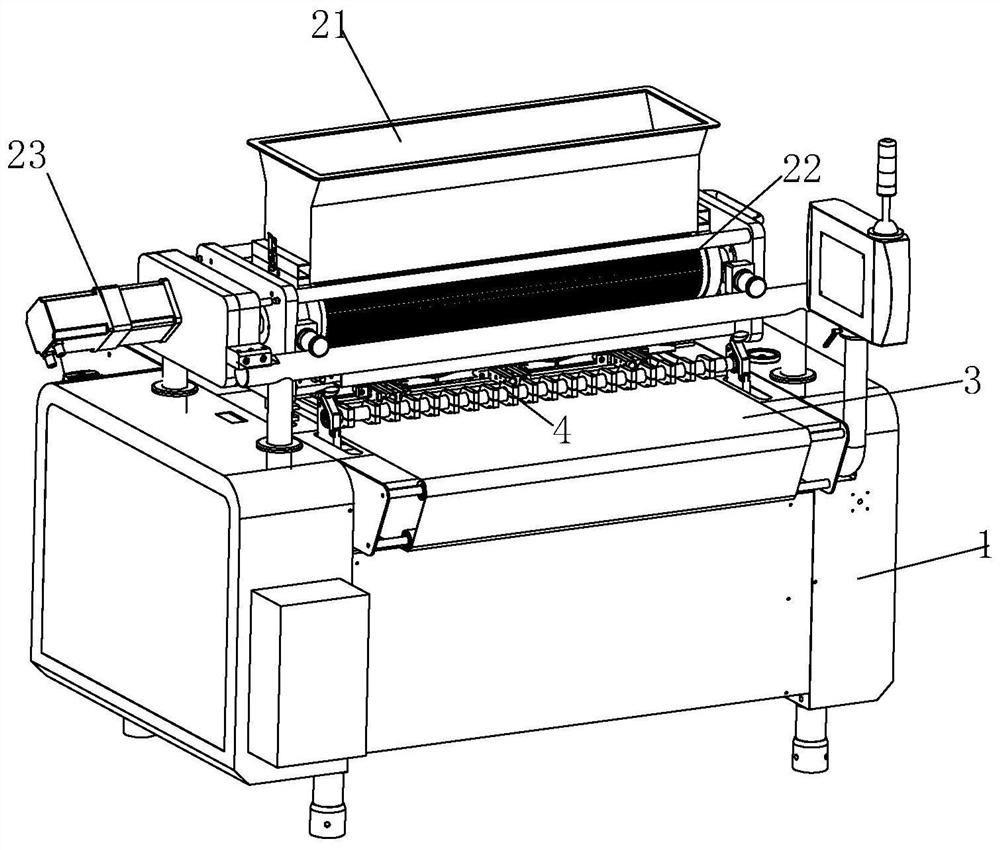

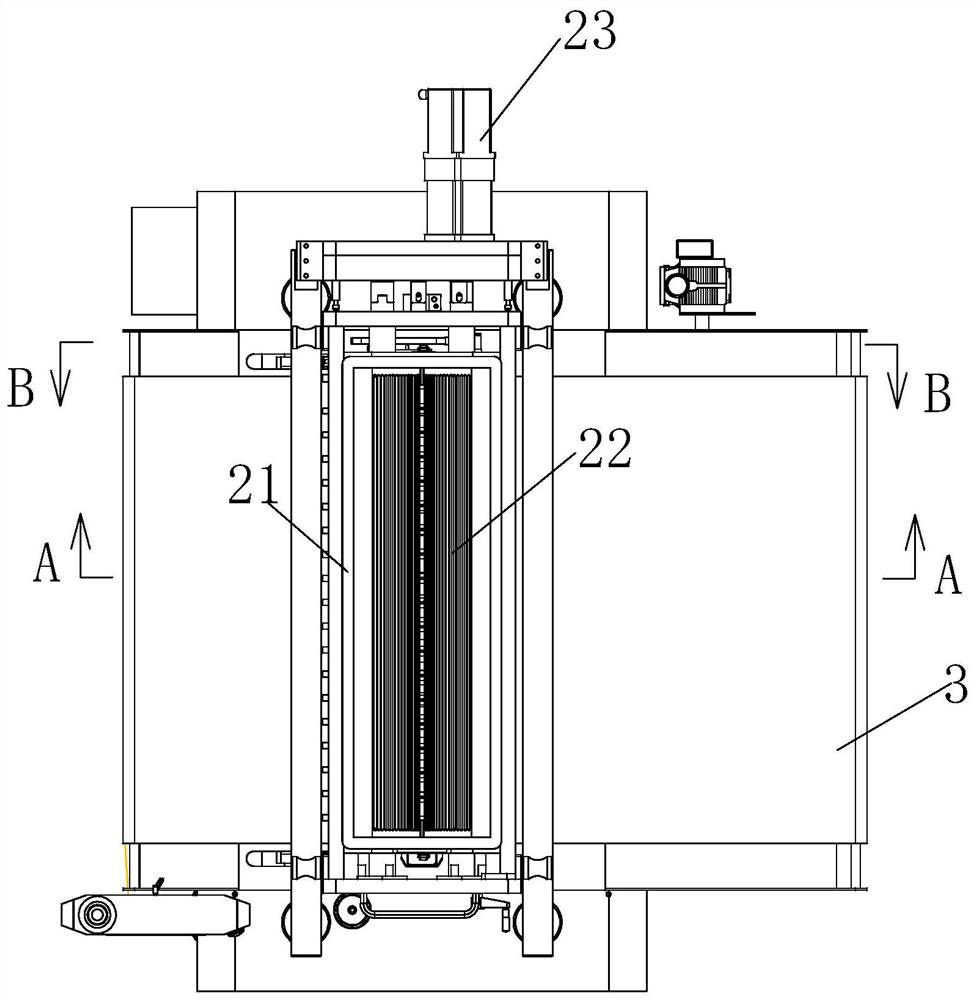

[0048] Embodiment one, such as Figure 1 to Figure 20 As shown, a cookie machine integrating knife cutting and wire cutting includes a frame 1 on which a workbench 500, a cookie conveyor belt 3, a dough feeding hopper 21, and a feeding roller are arranged. Assembly 22, dough discharge seat 20, knife cutting mechanism 4 and wire cutting mechanism 5, the dough feed hopper 21, feeding roller assembly 22 and dough discharge seat 20 are arranged on the frame 1 from top to bottom, so The dough discharge seat 20 is provided with a plurality of dough discharge holes 25 along the length direction of the dough discharge seat 20, the knife cutting mechanism 4 is arranged on the dough discharge seat 20, and the cookie conveyor belt 3 Circulating on the workbench 500, and located below the dough discharge seat 20, the wire cutting mechanism 5 includes a wire cutting motor 51, two front and rear swing arms 52, a swing arm rotating shaft 522, a cutting wire rotating shaft 55, and a lifting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com