Ultrasonic torsional vibration turning-milling system and method

A torsional vibration and ultrasonic technology, applied in the direction of driving devices, milling machine equipment, milling machine equipment details, etc., can solve the problems of difficult to guarantee machining accuracy, low machining quality, high turning and milling temperature, and achieve easy automatic chip removal, high machining quality, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

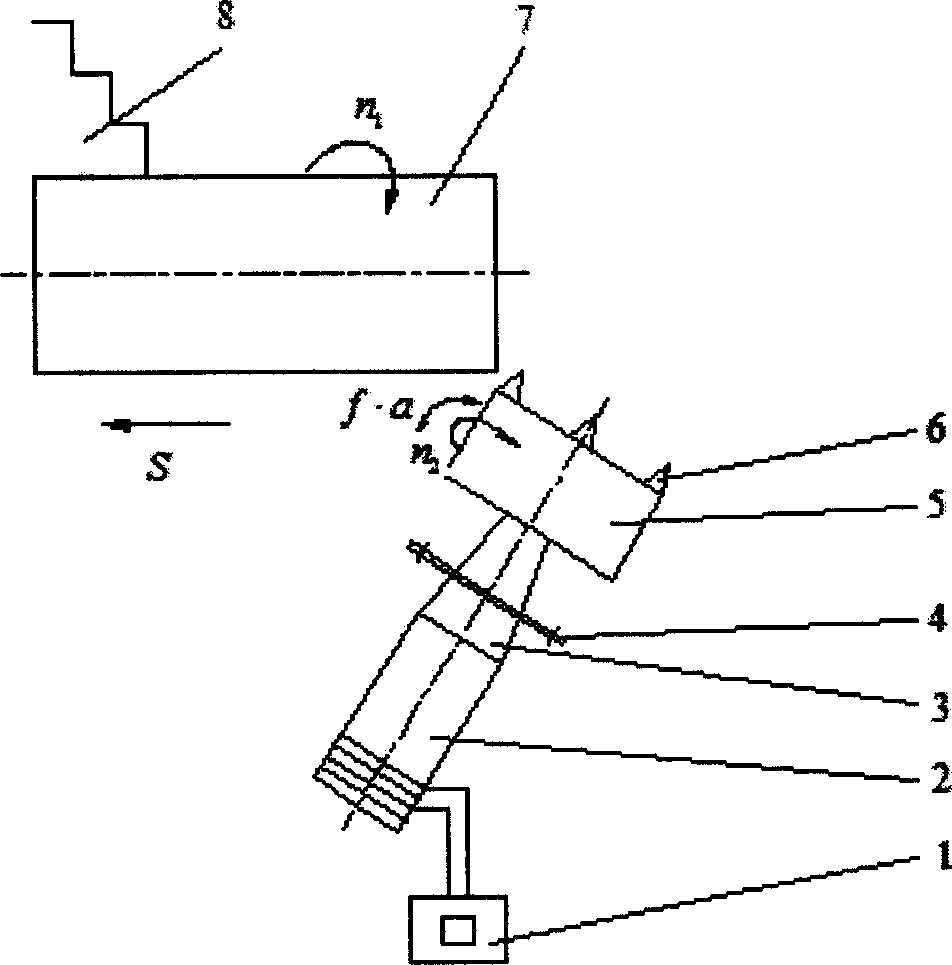

[0025] As shown in the attached figure, the ultrasonic torsional vibration turning and milling system adopts an ultrasonic torsional vibration turning and milling device in the turning and milling system. It has an ultrasonic generator 1, a torsional vibration sandwich piezoelectric transducer 2, a torsional vibration horn 3. Flange plate 4, milling cutter disc 5, cutter teeth 6, frame, torsional vibration sandwich piezoelectric transducer 2 connected to torsional vibration horn 3, milling cutter, milling cutter with milling cutter disc 5, Cutter teeth 6 are arranged on the milling cutter disc, and a flange 4 is arranged on the torsional vibration horn 3, and the flange 4 is connected with the frame.

[0026] The ultrasonic torsional vibration turning and milling method is to realize the cutting of the workpiece by using the synthetic motion of milling cutter rotation, workpiece 7 rotation, milling cutter axial feed, milling cutter radial feed, and milling cutter ultrasonic tor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com