Large-format laser high-speed machining mechanism

A processing mechanism and laser processing head technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as the influence of processing accuracy, achieve high processing efficiency, smooth mechanism operation, and improve laser processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention can be better described below in conjunction with the accompanying drawings and specific embodiments.

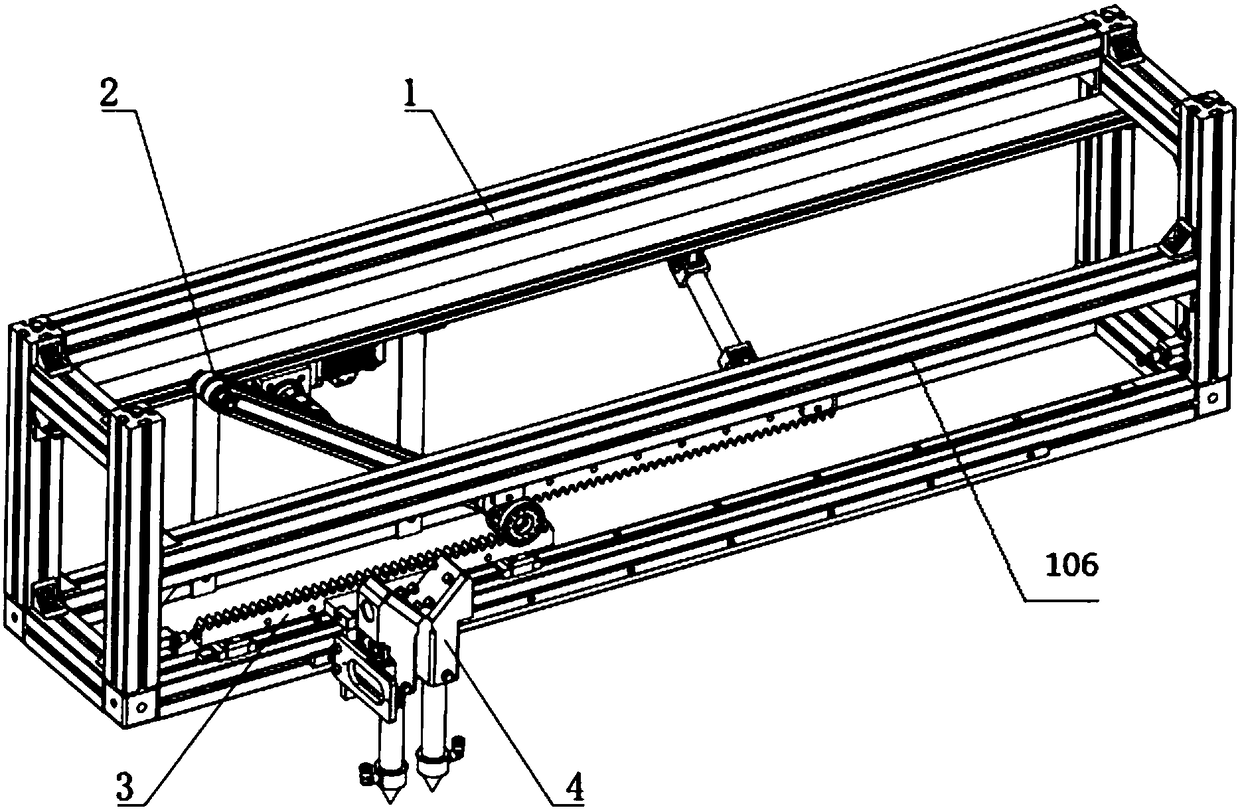

[0023] Such as figure 1 As shown, a large-format laser high-speed processing mechanism includes a frame main body 1, and the frame main body 1 is provided with a driving stepping motor 102, an offset crank slider mechanism 2, a linear differential stroke multiplying mechanism 3, and a laser processing head 4. Since laser processing is non-contact processing, the rigidity requirements of the mechanism are not high. In consideration of cost saving and light weight of the device, the frame body 1 of the overall mechanism is assembled from aluminum profiles 101.

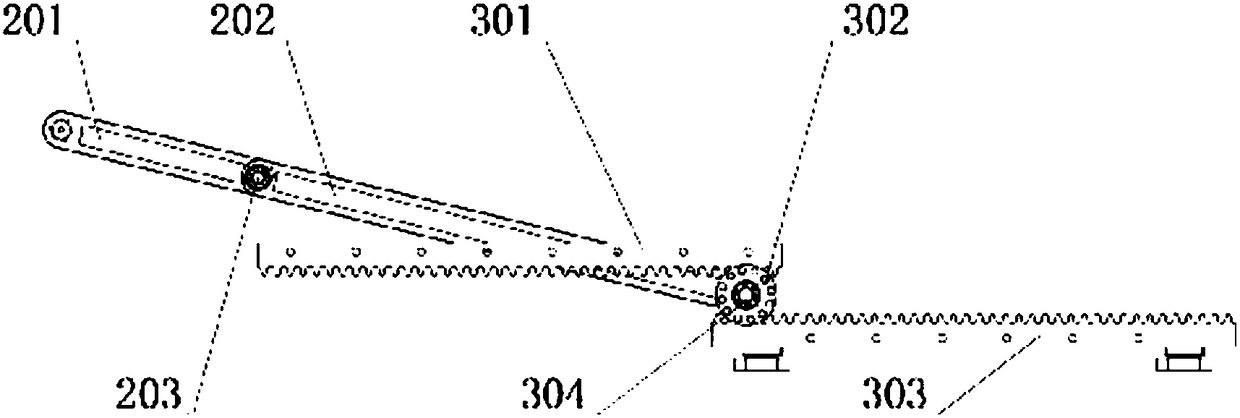

[0024] Such as figure 2 As shown, the offset crank-slider mechanism 2 includes a crank 201 and a connecting rod 202 connected to the driving stepper motor 102, and the crank 201 and the connecting rod 202 are hinged through a connecting groove nut 203, and the straight line The different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com