Electric oilseed rape circulating cutting and airing machine allowing middle laying

A circulating, windrower technology, applied in the direction of cutters, harvesters, chassis of agricultural machinery, etc., can solve the problems of complex structure of conveying and laying devices, low cutting speed of cutting devices, and large loss of headers, etc., and achieves improvement. Ventilation effect, compact equipment, flexible operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

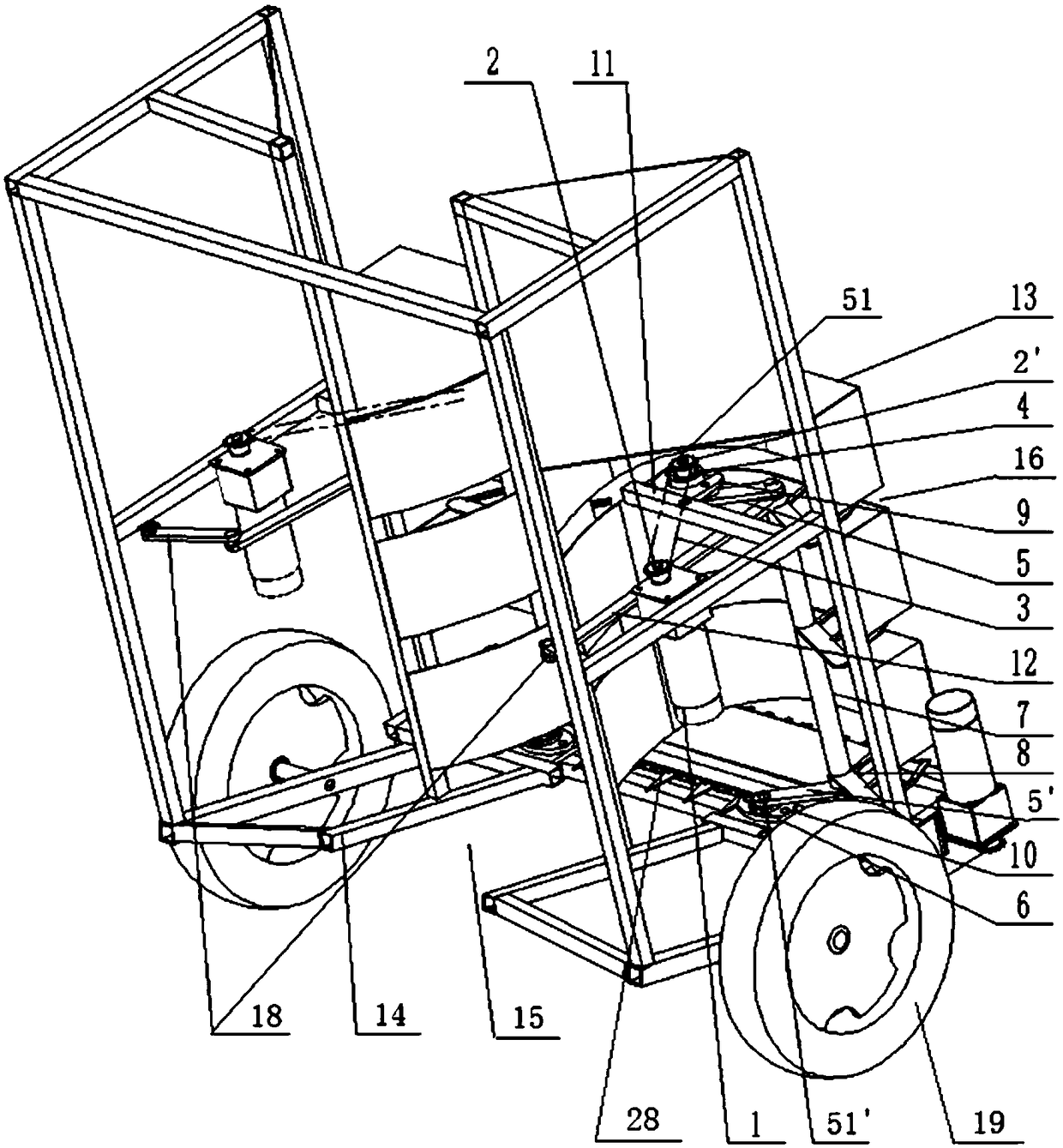

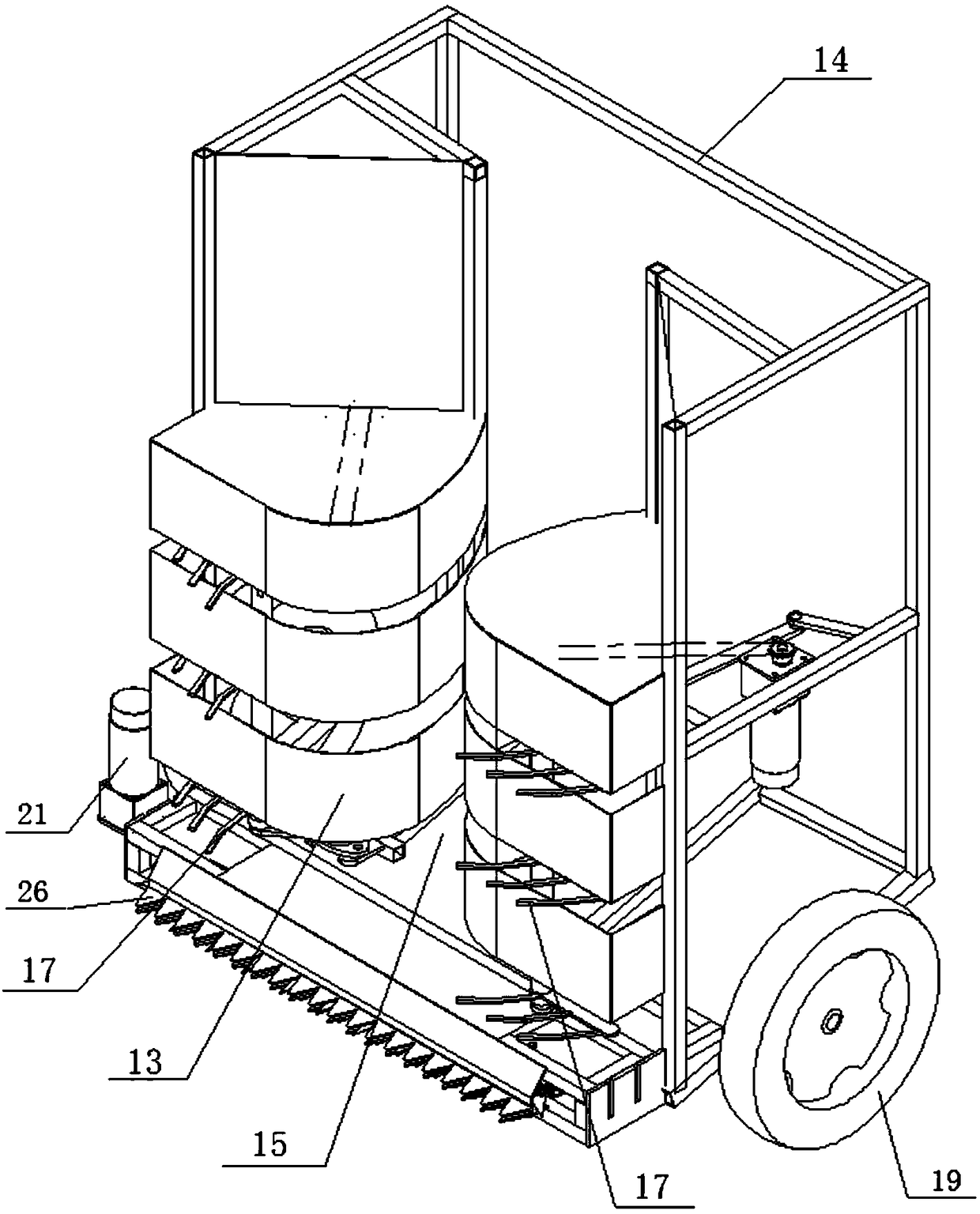

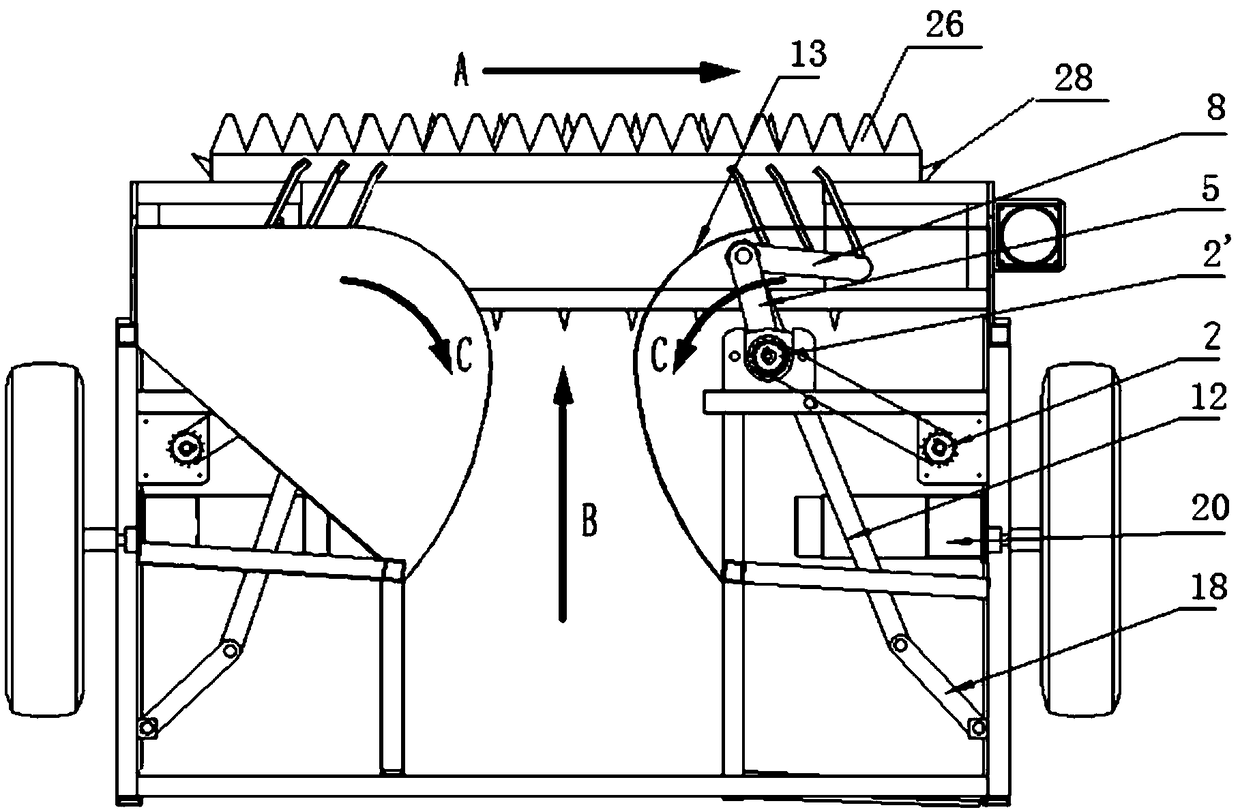

[0024] like Figure 1-Figure 5 As shown, a circular cutting middle laying electric rape windrower of the present invention includes a walking mechanism connected and fixed to the frame 14, a cutting mechanism and a reeling and laying mechanism.

[0025] The traveling mechanism includes traveling wheels 19 pivotally connected to both sides of the bottom of the frame 14 , the traveling wheels 19 are connected to the first motor 20 , driven by the first motor 20 , the traveling wheels 19 realize walking.

[0026] This cutting mechanism comprises the second motor 21 that is installed on the frame 14, and the output shaft of the second motor 21 is provided with the first sprocket 22, and the first sprocket 22 is connected the second sprocket 23 through the chain, and the second sprocket 23 is coaxially installed with cutting drive sprocket 24, and cutting chain 25 is installed between cutting drive sprocket 24 and cutting driven sprocket (not shown in the figure), and the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com