Cutting equipment for plastic particle processing

A technology of plastic granules and equipment, applied in the field of plastic processing, can solve the problems of uneven size and shape of plastic granules, dull blade, and reduced work efficiency, achieve uniform size and shape, high-speed continuous cutting, avoid too little or too much The effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above scheme will be further described below in conjunction with specific embodiments. It should be understood that these examples are intended to illustrate the invention and not to limit the scope of the invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not specified are usually the conditions in routine experiments.

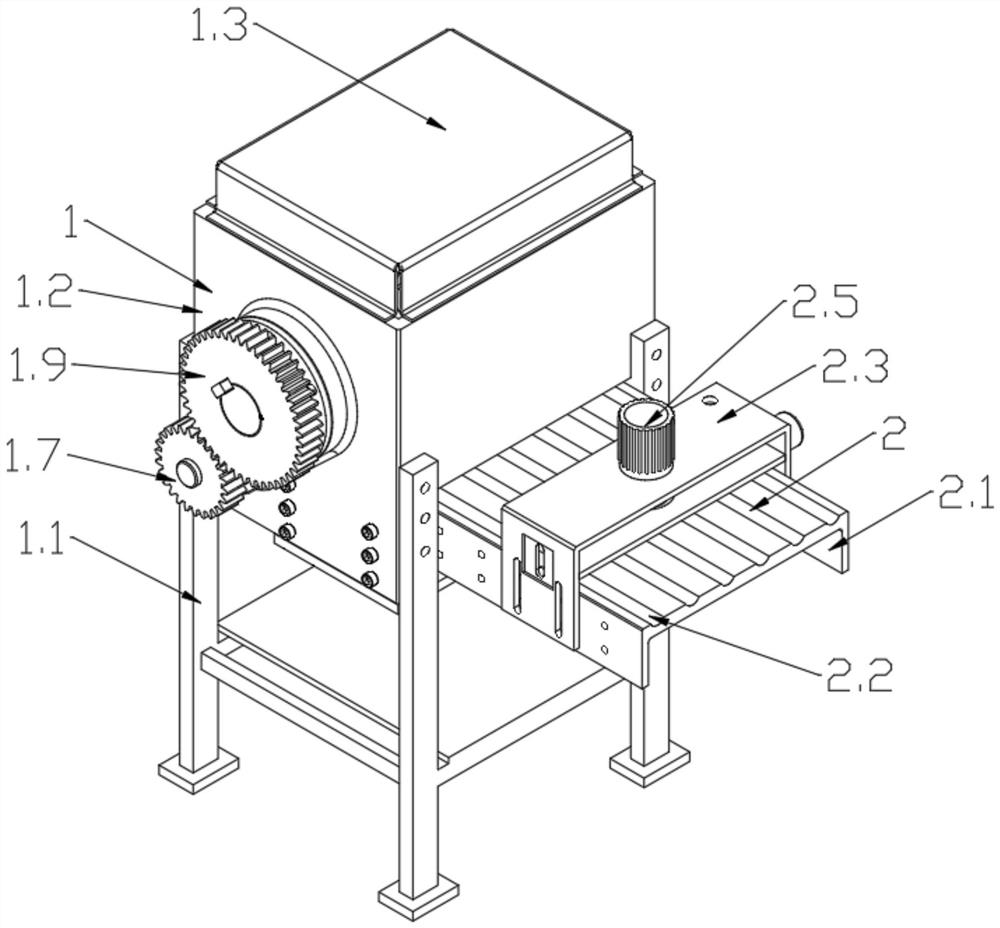

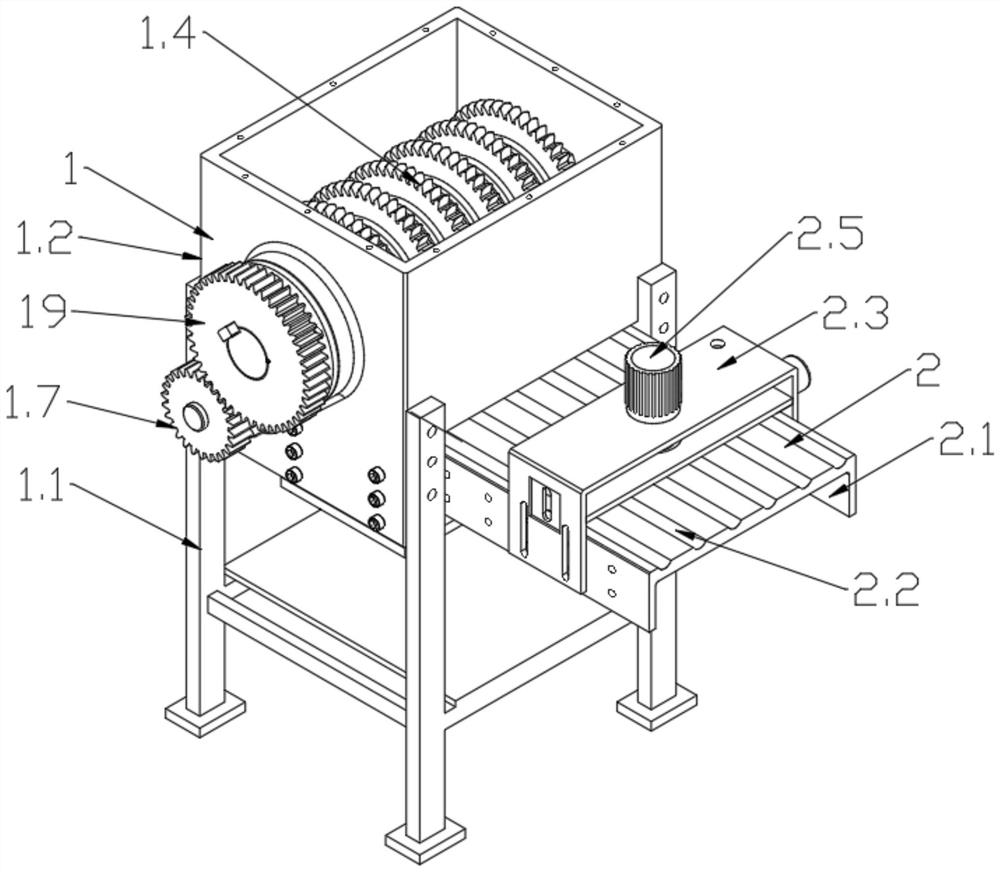

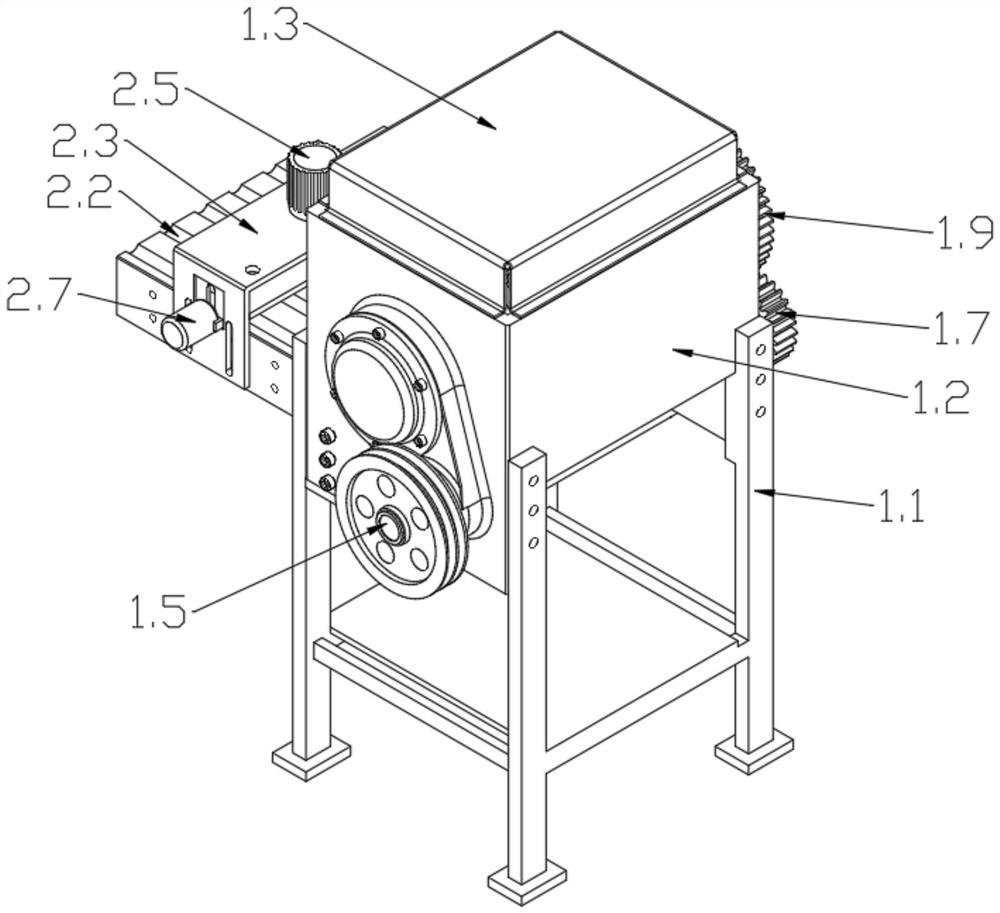

[0033] In a specific embodiment, a cutting device for processing plastic particles is provided, including a cutting device 1 and a feeding device 2. The cutting device 1 includes a mounting frame 1.1, a cutting box 1.2 and a cutting gear 1.4, and the upper end of the mounting frame 1.1 is provided. A cut-off box 1.2 is provided, and the cut-off gears 1.4 are multiple and circumferentially fixedly sleeved on the first transmission shaft 1.8. Specifically, the number of cut-off gears 1.4 can be exchanged according to actual prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com